Square section type prestress ultra-high performance concrete pipe combined column

An ultra-high performance, concrete pipe technology, applied in the direction of columns, piers, pillars, etc., can solve the problems of limited length, application restrictions, and inability to transmit the tensile force of longitudinal bars downward, and achieves convenient length, simplified construction, and convenient adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

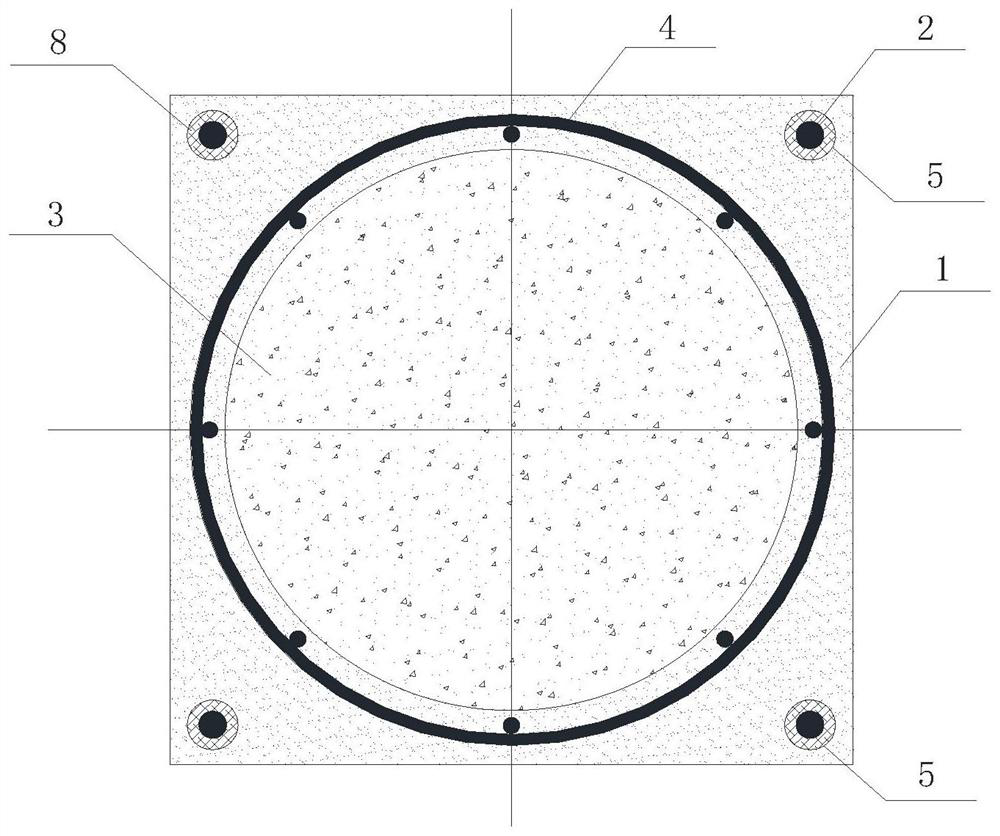

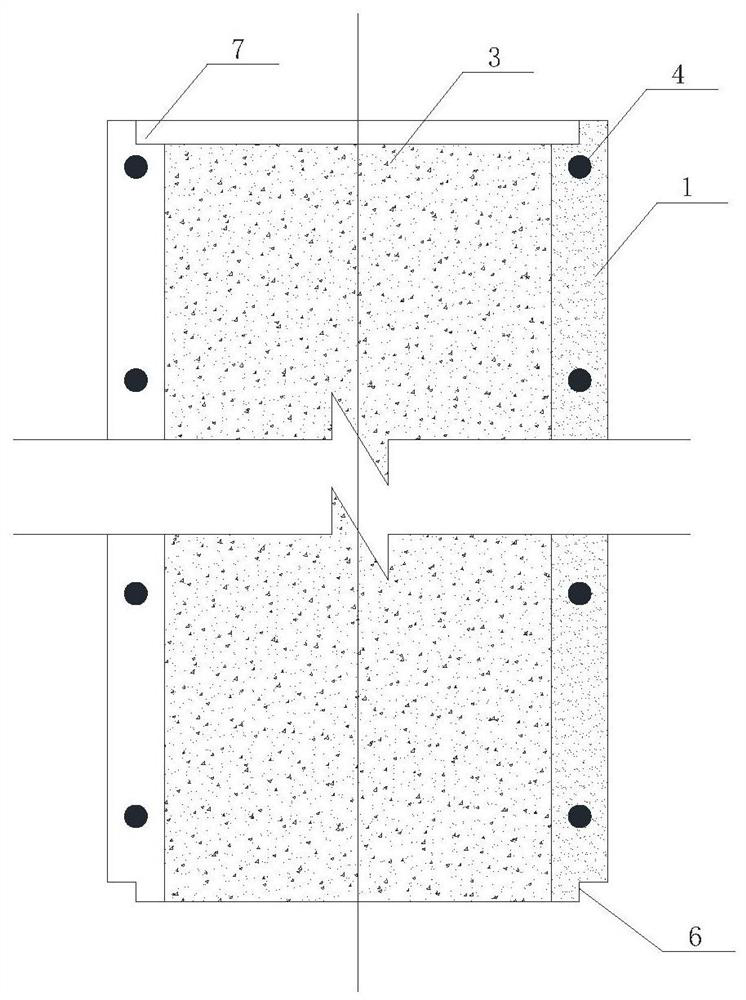

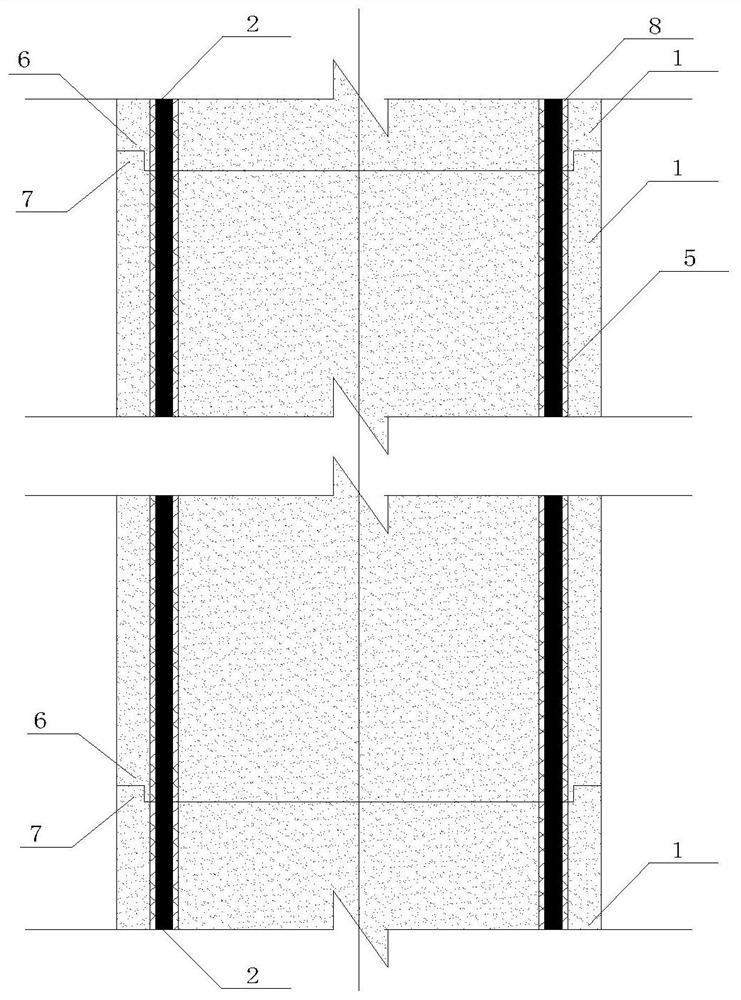

[0021] The invention is attached figure 1 , attached figure 2 And attached image 3 As shown, the square segmental prestressed ultra-high performance concrete pipe composite column includes ultra-high performance concrete pipe joints (1) and prestressed longitudinal bars (2), and ultra-high performance concrete pipe joints (1) (2) connect them, and pour concrete (3) inside; it is characterized in that: the ultra-high-performance concrete pipe joint (1) is an empty pipe with a square outside and a circle inside, which is formed by centrifugal method. The stirrup (4) is closed, and a long reserved channel (5) is arranged at the corner along the longitudinal axis, and a male interface (6) and a female interface (7) are respectively arranged at both ends; the prestressed longitudinal reinforcement (2 ) through the reserved channels (5) of one or more ultra-high-performance concrete pipe joints (1), and apply an axial preload to the ultra-high-performance concrete pipe joints (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com