Stirring rotary type screening device for can production

A screening device and rotary technology, which is applied in the field of rotary rotary screening devices for can production, can solve the problems of lowering sales competitiveness, affecting the quality of cans, and low work efficiency, avoiding easy damage, facilitating protection, and saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

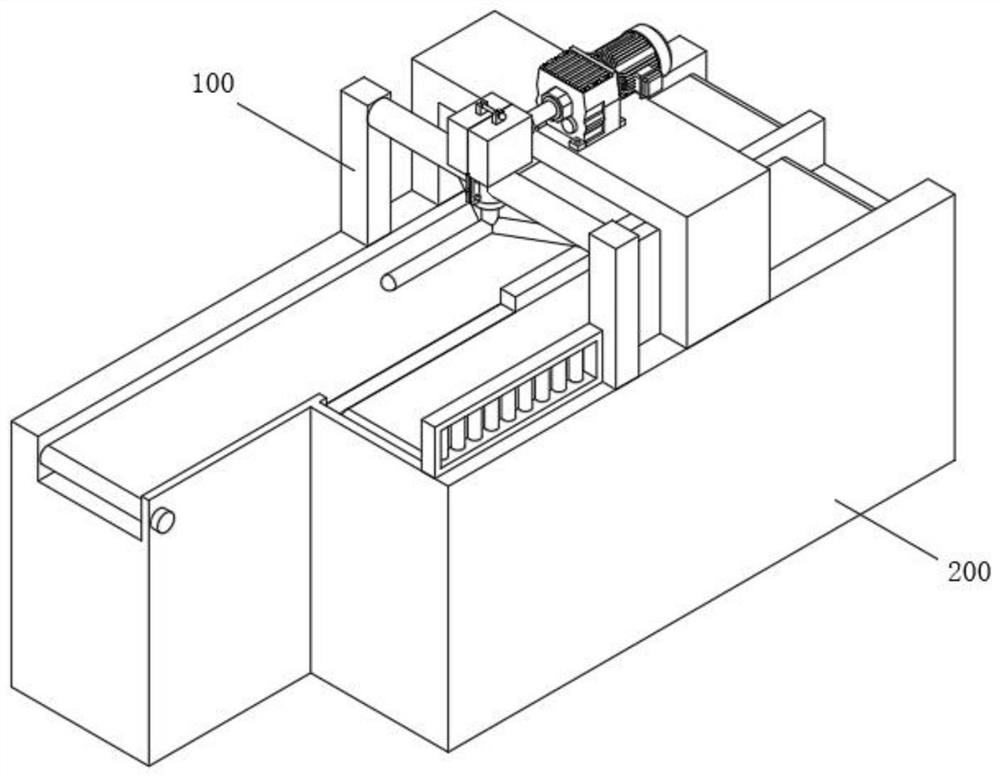

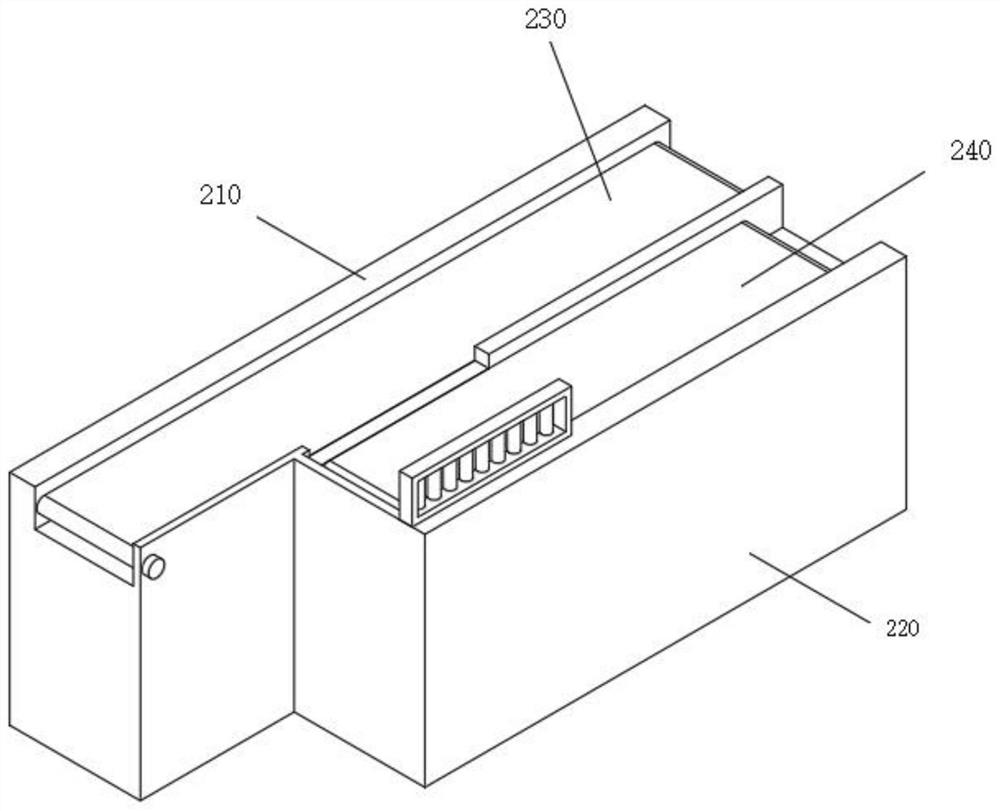

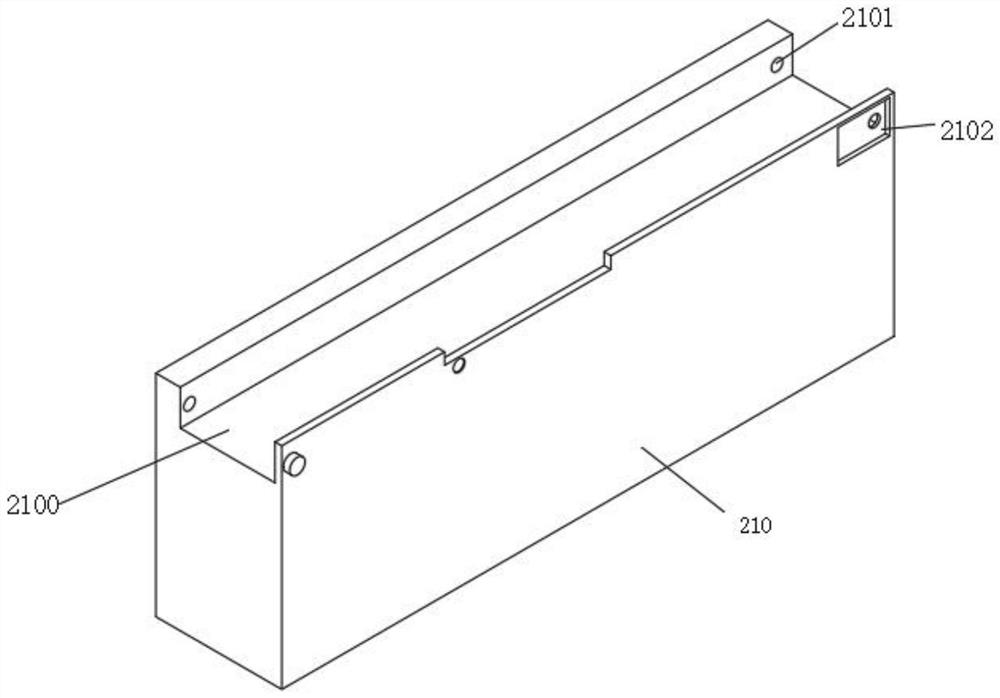

[0062] see Figure 1-Figure 14 As shown, the present embodiment provides a screening device for toggle rotary can production, including a conveying device 200 and a screening device 100 installed above the conveying device 200. The conveying device 200 includes a left conveying platform 210 and a The right conveying platform 220 on the right side of 210, the left conveying platform 210 is connected with the left conveyer belt 230 by the left groove 2100 that offers inside, and left conveyer belt 230 front and rear ends all rotate and be connected with left turn bar 231, left groove 2100 front and back two The end and side walls are all provided with a left groove turning hole 2101, and the left turning rod 231 is connected with the left groove turning hole 2101 in rotation, and the left conveyor belt 230 is driven to rotate inside the left groove 2100 through the driving device, so as to be convenient to the left conveyor belt 230. The cans on the surface are transported, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com