Bending mechanism and bending method for wiring terminal of radio frequency coaxial connector

A terminal, radio frequency coaxial technology, applied in the field of assembly equipment, can solve the problems of inconsistent pin shape, inability to accurately locate the bent part, and inability to guarantee the effect of bending, and achieve the effect of ensuring the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

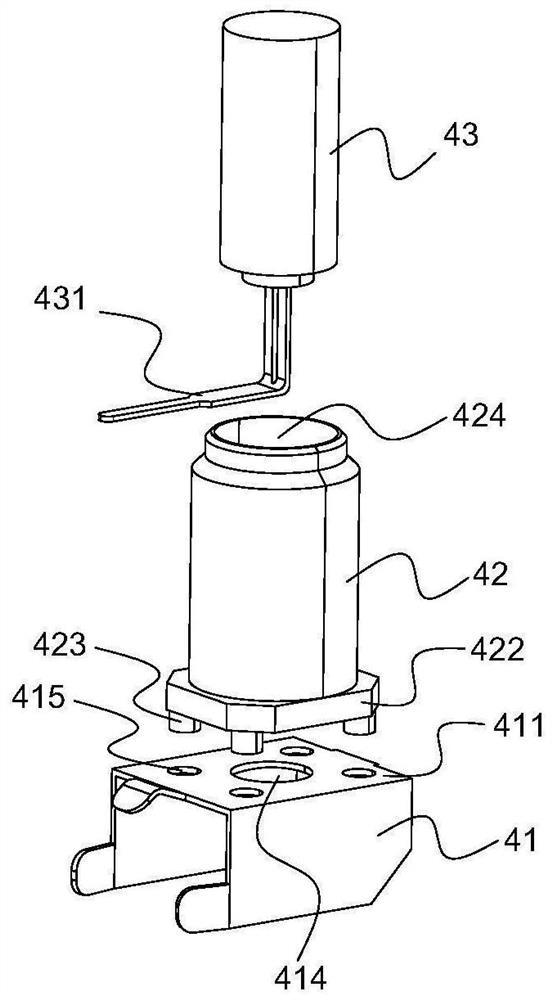

[0022]Such asfigure 1 As shown, a terminal bending mechanism of a radio frequency coaxial connector includes a frame and a material frame 217 installed on the frame, a first pre-compression component 241, a second pre-compression component 242, and side bending The component 243 and the bottom bending component 244; the material rack 217 is provided with a feeding channel; the material rack 217 is provided with a first bending station and a second bending station; the position of the first pre-compression component 241 is the same as that of the first bending The bending station is matched; the position of the second pre-compression component 242 matches the second bending station; the first pre-compression component 241 and the second pre-compression component 242 are located on the same side of the material rack 217; the side bending component 243 is installed On the other side of the material rack 217, the side bending component 243 is simultaneously matched with the first pre-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com