Fin heat exchange tube cleaning equipment

A technology for cleaning equipment and heat exchange tubes, applied in lighting and heating equipment, flushing, cleaning heat transfer devices, etc., can solve the problem of inability to clean finned heat exchange tubes, and achieve high cleaning efficiency and high cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

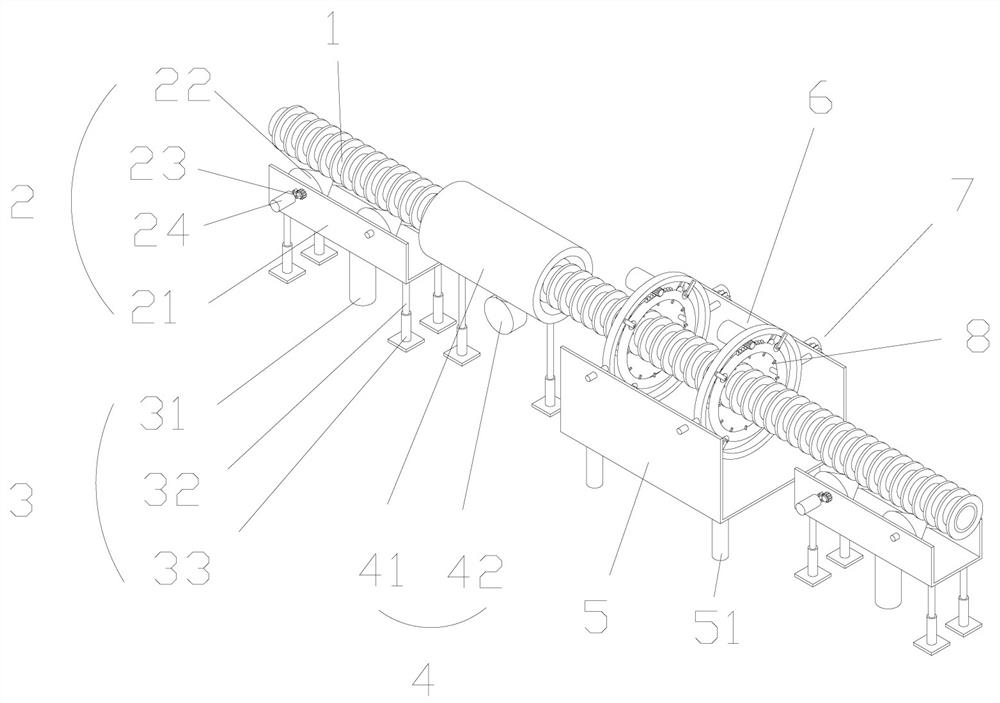

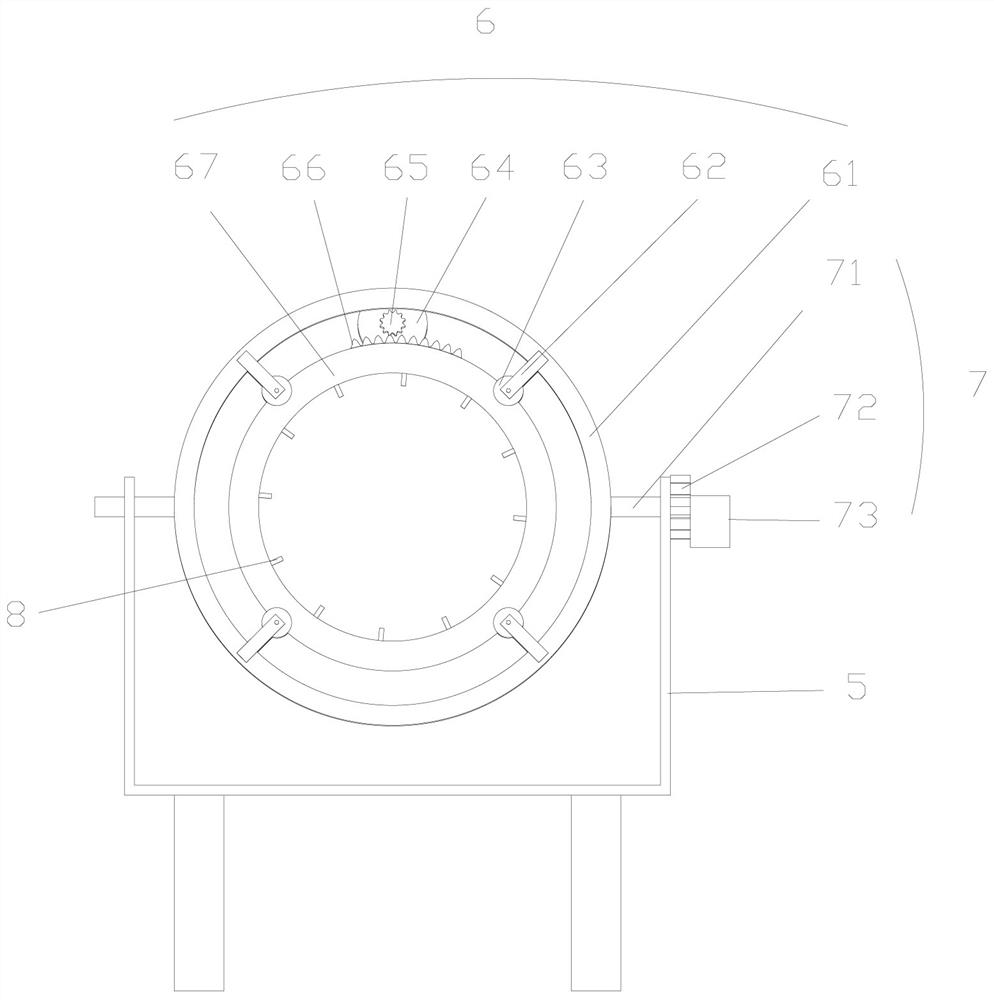

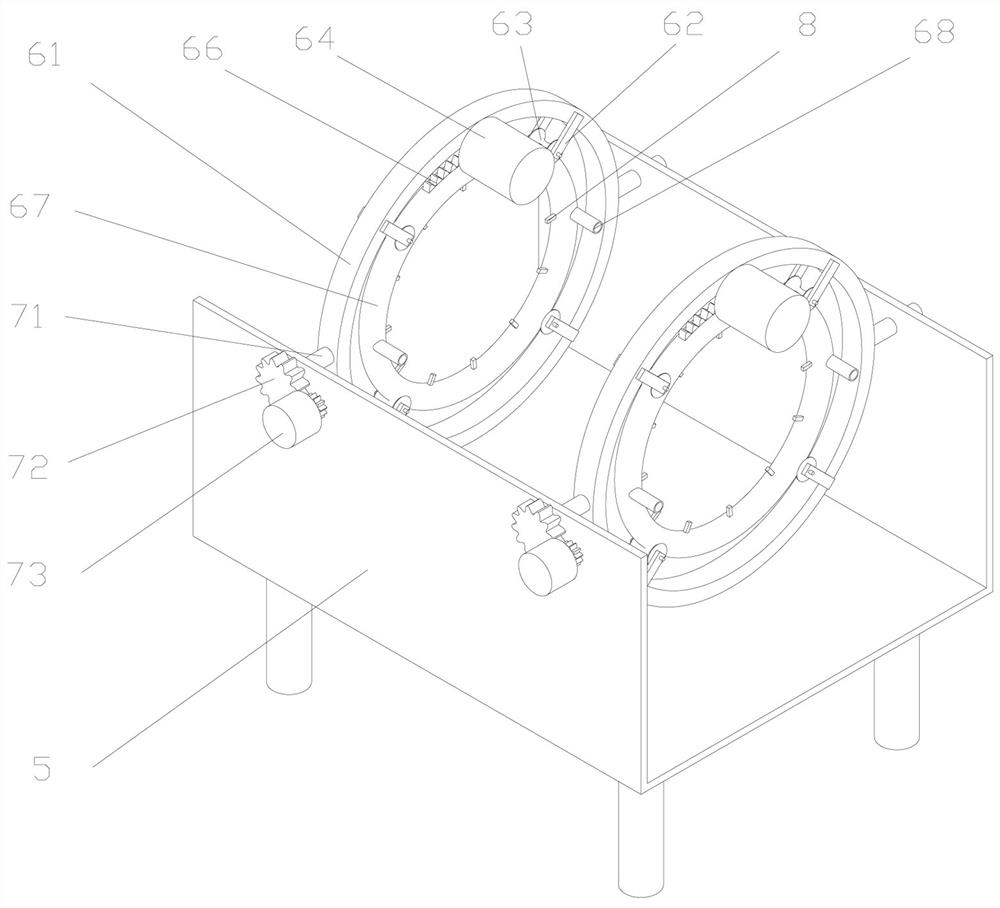

[0033] In order to more clearly illustrate the embodiments of the present invention and the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Apparently, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings according to these drawings without any creative work. and obtain other implementations. In addition, the belonging of the design orientation only indicates the relative positional relationship between the components, not the absolute positional relationship.

[0034]Finned heat exchange welded tubes need to use emulsion for cooling and lubrication during processing. After processing, the emulsion and processing impurities will remain on the surface of the finned tube and in the gap between the fins. In the subsequent process, the emulsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com