All-working-condition heat-pump heat recovery type fresh air ventilator with multiple reheating modes

A technology of heat recovery type and all working conditions, applied in the direction of heating method, heat recovery system, energy recovery system of ventilation and heating, etc., can solve the problems of unsatisfactory air supply temperature, blowing feeling, and difficulty in guaranteeing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

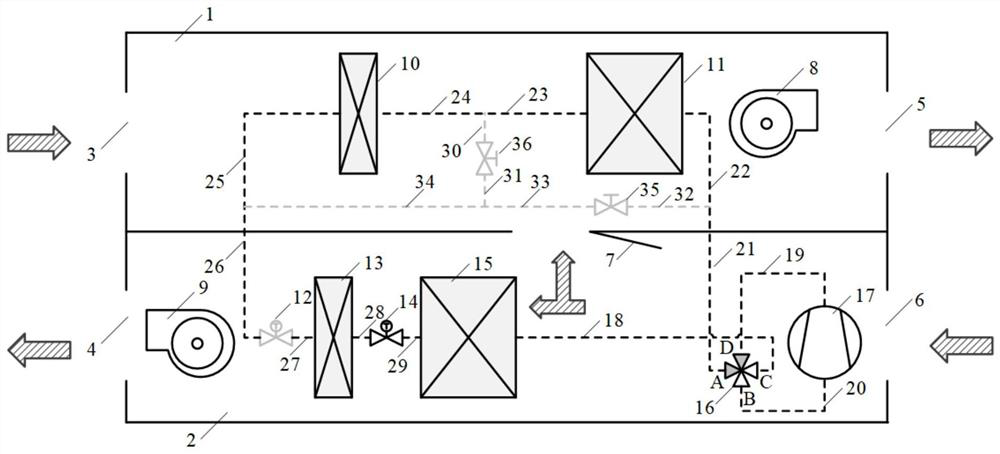

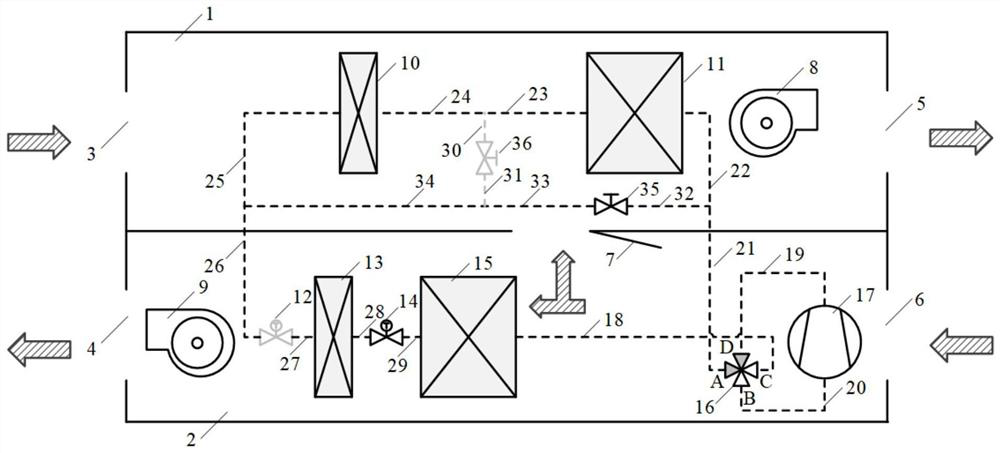

[0079] In this embodiment, a full-working-condition heat pump heat recovery fresh air fan with multi-reheating mode has a structure such as figure 1 As shown, the main structure includes the first air duct 1, the second air duct 2, the return air outlet 3, the air supply outlet 4, the exhaust air outlet 5, the fresh air outlet 6, the mixing air door 7, the exhaust fan 8, and the air supply fan 9. Subcooling coil 10, exhaust coil 11, first throttling device 12, reheat coil 13, second throttling device 14, air supply coil 15, four-way reversing valve 16, compressor 17 , connecting the pipelines 18-34, the first shut-off valve 35, and the second shut-off valve 36.

[0080] In this embodiment, the compressor 17, the connecting pipe 19, the four-way reversing valve 16, the connecting pipes 21, 22, the refrigerant flow path of the exhaust coil 11, the connecting pipes 23, 24, and the refrigerant of the subcooling coil 10 Flow path, connecting pipes 25, 26, first throttling device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com