Device and method for improving color fastness of denim

A cloth color, denim technology, applied in the processing of textile materials, textile and papermaking, liquid/gas/vapor textile processing and other directions, can solve the problem of insufficient effect, and achieve the effect of high cost performance, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

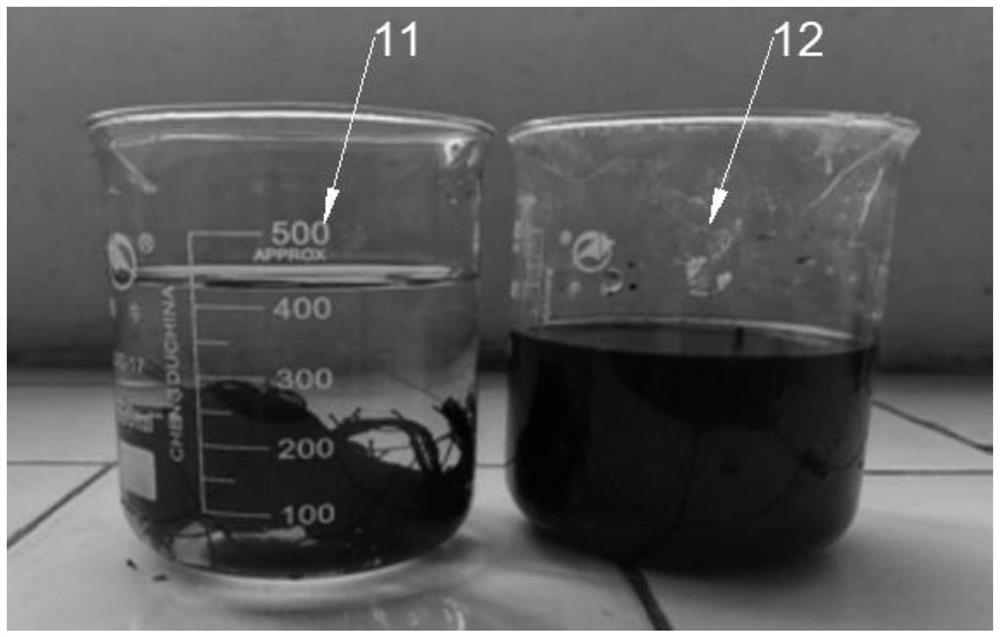

Examples

Embodiment 1

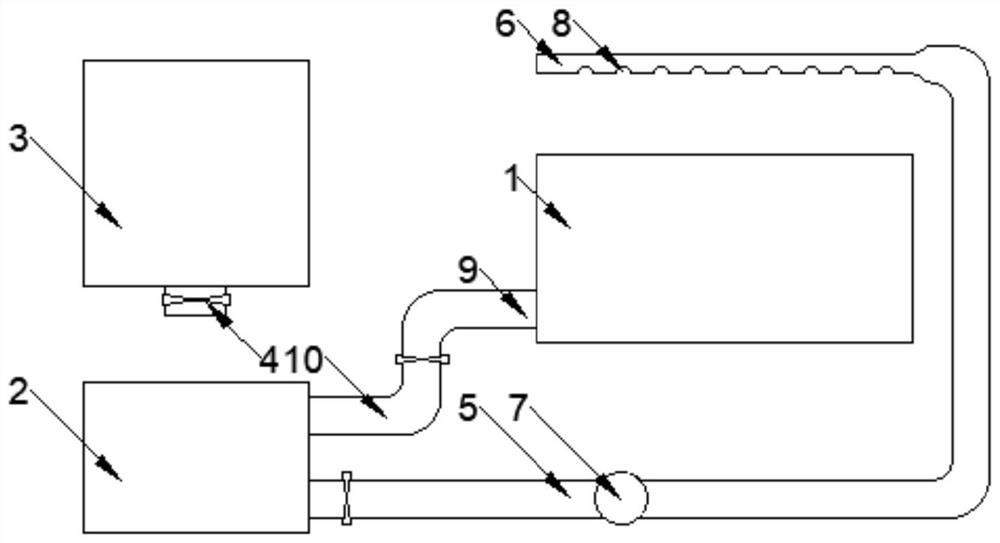

[0024] Such as figure 1 As shown, a device for improving the color fastness of denim, the device includes a pickling tank 1, a circulation cylinder 2 and a feed tank 3, wherein the volume of the circulation tank 2 is 600×400×450mm, and the volume of the feed tank 3 is 600× 600×600mm, the height of the circulation cylinder 2 does not exceed the height of the pickling tank 1, the pickling tank is provided with the pickling tank feed pipe 6 and the pickling tank discharge pipe 9, the circulation cylinder 2 is provided with the circulation cylinder discharge pipe 5 and the circulation Cylinder return pipe 10, feeding barrel is provided with feeding barrel discharging pipe 4,

[0025] The feeding pipe 4 of the feeding barrel is set above the circulation cylinder 2 for replenishing acetic acid into the circulation cylinder 2, the circulation cylinder discharge pipe 5 is connected with the pickling tank feeding pipe 6, and the circulation cylinder discharge pipe 5 is set 2, the circ...

Embodiment 2

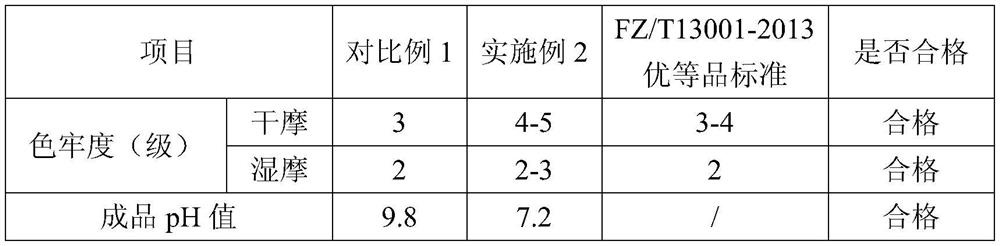

[0029] A method for improving the color fastness of denim using the above-mentioned device, the method is that after the warp yarn is dyed and washed, it is immersed in a pickling tank for pickling, wherein

[0030] The specification of warp yarn is 10,

[0031] The dyeing process uses sulfur black and sulfurized alkali at a mass ratio of 1:2 to dye at 90°C.

[0032] The temperature of the water washing process is 60°C, and the time is 10min.

[0033] The pickling process uses acetic acid with a pH value of 4 to 6, and the acetic acid supply to the pickling tank is controlled at 50mL / 30″.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com