Anti-garbage-pinching automatic door closing system and control method for split type garbage compression equipment

A technology of garbage compression and automatic door closing, which is applied in the direction of garbage bins, garbage collection, waste collection and transfer, etc., which can solve problems such as difficult to eliminate garbage, polluted road surface cleaning, and inaccurate limit switch position collection, so as to prevent garbage from being trapped and garbage hanging, improving human-machine efficiency, and avoiding administrative penalties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

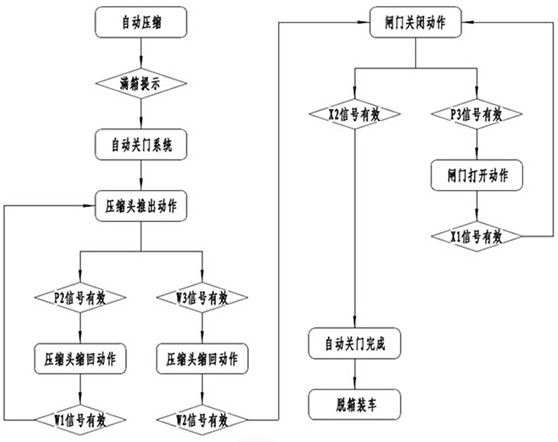

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

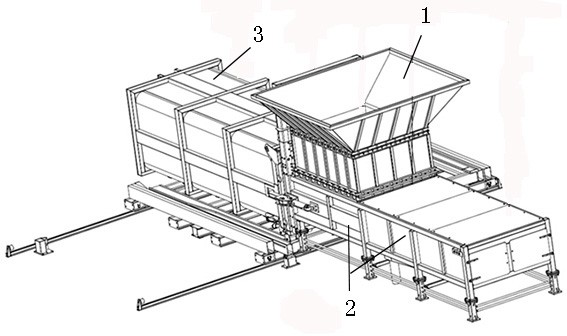

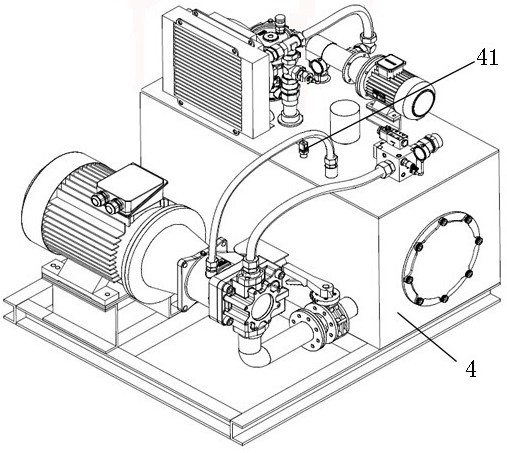

[0044] Such as Figure 1 to Figure 5 As shown, a split-type garbage compression equipment anti-trap automatic door closing system includes a compression head mechanism, a gate opening and closing mechanism, a hydraulic control module 4, a displacement sensor 5, an electrical control module 6, a full box alarm device and a proximity switch.

[0045] The compression head mechanism includes a compression head. The hydraulic control module 4 is connected with the compression head mechanism and the gate opening and closing mechanism, and is used to drive the compression head mechanism to perform a garbage compression operation or drive the gate opening and closing mechanism to perform a gate opening and closing operation, including for collecting Pressure sensor 41 for hydraulic system pressure informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com