Baseball pitching machine

A ball machine and baseball technology, applied to rackets, sports accessories, etc., can solve the problems of electric shock hazard, unfavorable outdoor use, unstable base, etc., achieve easy disassembly and installation, one machine with dual-purpose practicability, and improve the technical level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

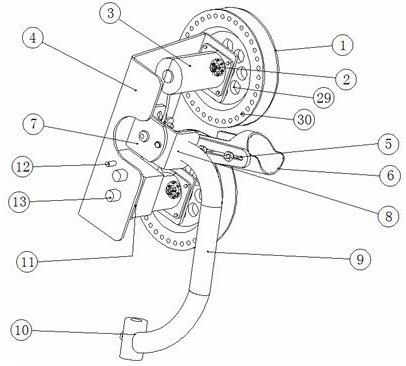

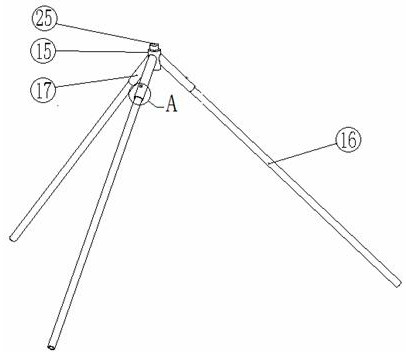

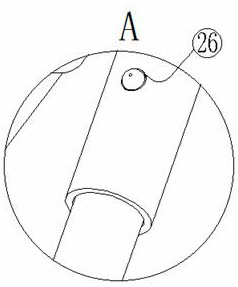

[0037] Such as Figure 1-12As shown, it includes a storage battery 18, an AC / DC power converter 19, an upper part 20, a lower part 21, and a steering part 22 connecting the upper part 20 and the lower part 21. It is characterized in that the upper part includes: Friction wheel 1, flange 2, motor 3, panel 4, goal cylinder bracket 5, goal cylinder 6, corner brace I7, corner brace II8, intermediate bracket 9, connecting sleeve 10, control box 11, power switch 12, Governor 13, wherein, the core of the friction wheel 1 is an aluminum alloy wheel hub, and the aluminum alloy wheel hub is covered with a polyurethane rubber wheel, and the friction wheel 1 and the flange 2 are connected by bolts. The flange 2 is connected with the motor shaft of the motor 3, and the motor 3 is connected with the panel 4 by bolts to increase structural stability; the goal cylinder support 5 is connected with the goal cylinder 6 by bolts, and the progress Bar-shaped grooves are opened on the ball barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com