Cooling arrangement for a high voltage power device

A technology of high-voltage power equipment and cooling devices, which is applied in the direction of transformer/inductor cooling, transformer/inductor parts, heat storage equipment, etc., can solve the problems that the aging of insulating materials affects the expected life of high-voltage power equipment, and achieve flexible cooling, Effect of increasing thermal inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

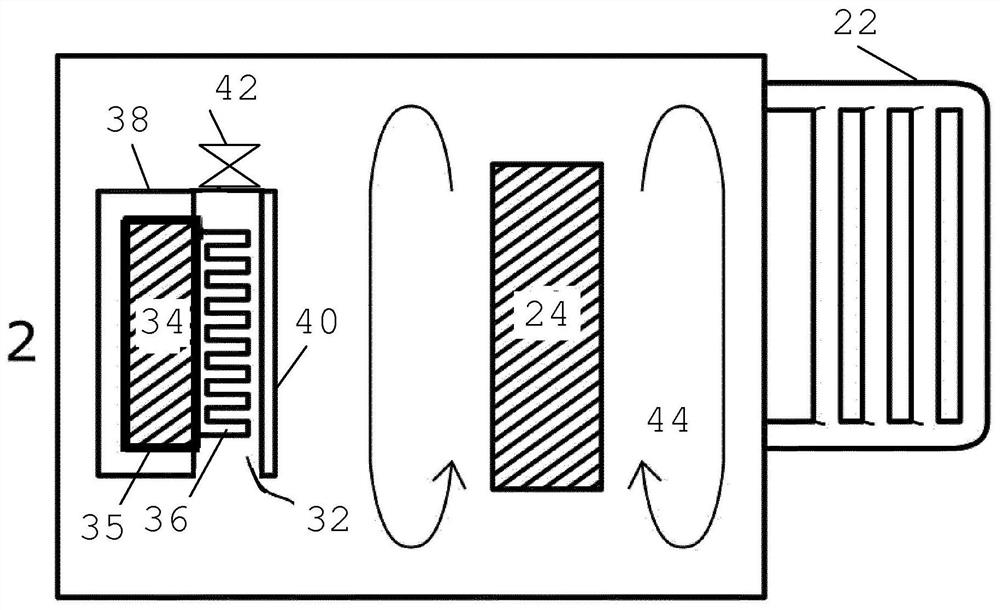

[0039] The present invention relates to high-voltage electrical equipment, such as power transformers such as transformers, power switches, power converters, reactors or electric motors, cooled by using an insulating fluid such as transformer oil.

[0040] The invention relates more particularly to a cooling arrangement for such high-voltage electrical equipment, comprising a cooling device. In some variants, it also includes a control device controlling the valve of this cooling device. The invention also relates to a high-voltage electrical installation comprising a high-voltage electrical device, an enclosure for accommodating the high-voltage electrical device and such a cooling device.

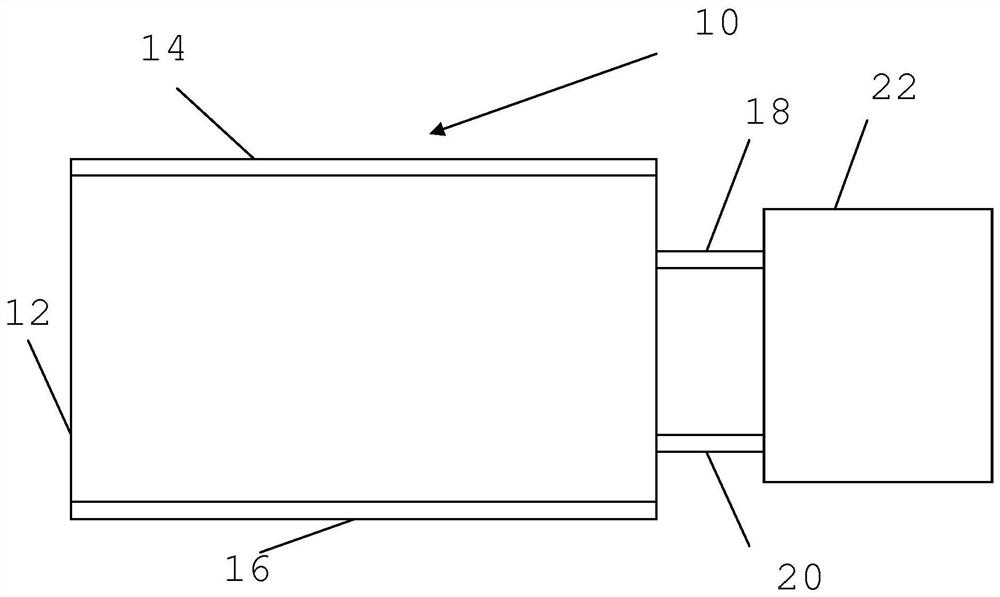

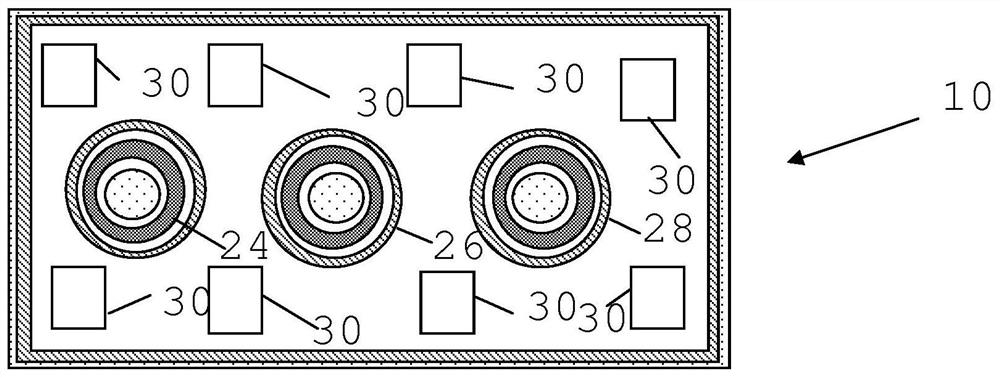

[0041] In FIG. 1, a side view of an exemplary first enclosure for housing such a voltage electrical device is shown. For example, the high-voltage power equipment is a transformer, so the first enclosure is the transformer box 10 . The transformer tank 10 has at least one wall 12 , a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com