Heat dissipation and temperature rise method for power storage device of new energy automobile

A new energy vehicle and power storage device technology, which is applied in battery temperature control, batteries, circuits, etc., can solve the problems of poor shock resistance of power storage devices, inability to adjust the temperature of power storage devices, and general heat dissipation effect, etc., to improve the shock resistance performance , good temperature environment, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

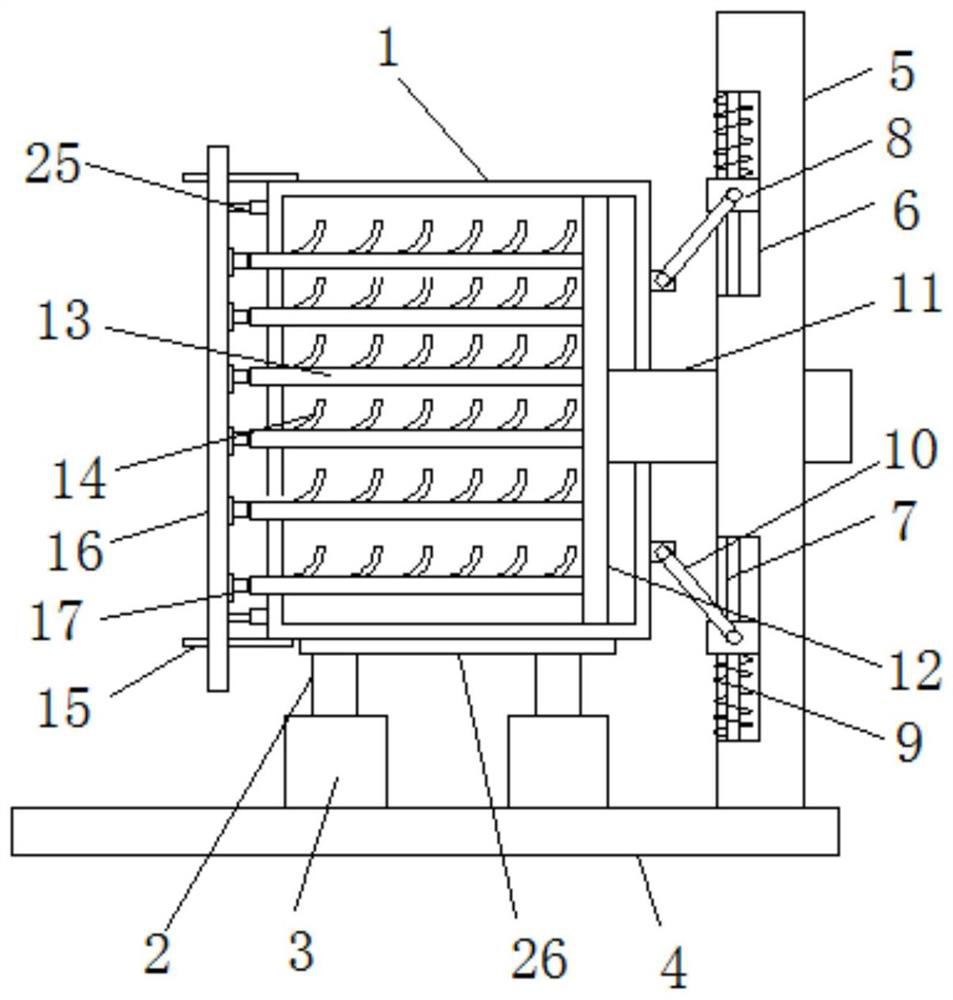

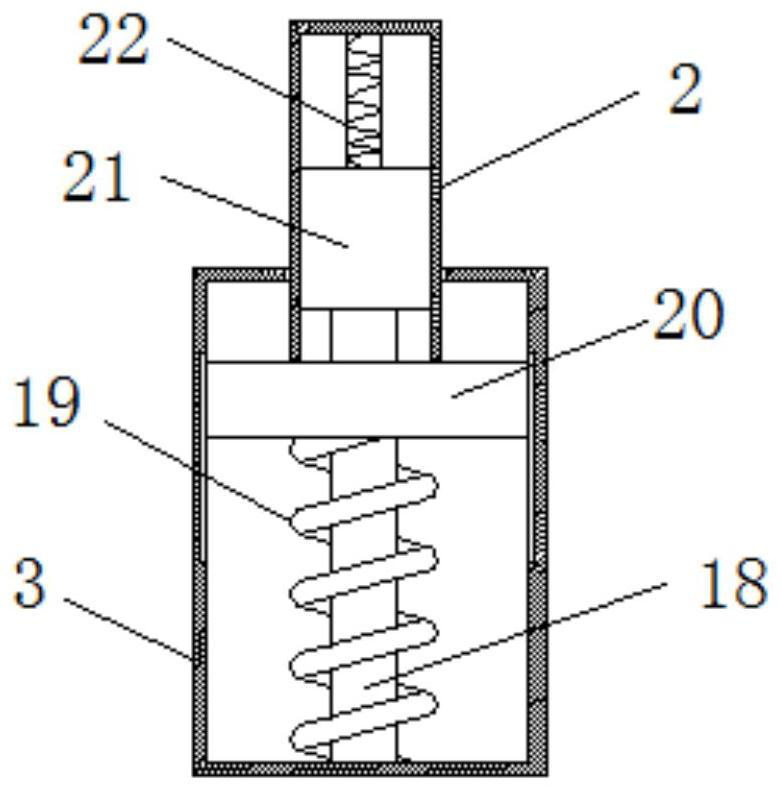

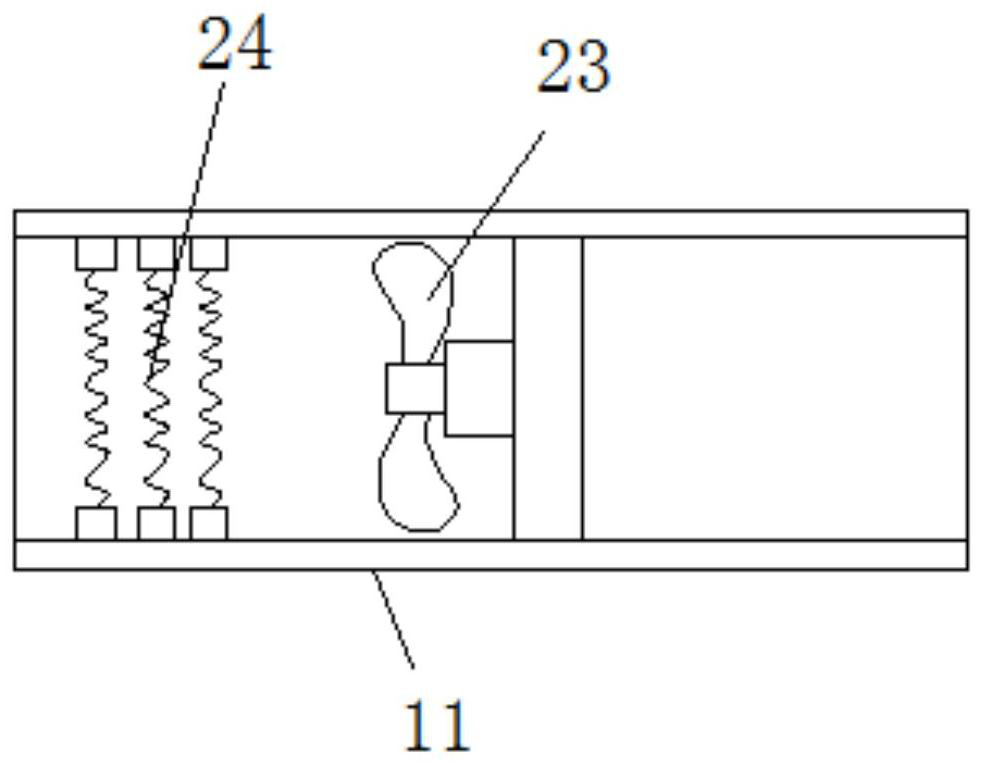

[0021] refer to Figure 1-3 , a new energy vehicle power storage device, comprising a casing 1, a support plate 26 is slidably installed on the bottom of the casing 1, a first column 2 is fixedly connected to the bottom of the support plate 26, and the bottom of the first column 2 is slidably connected to There is a second cylinder 3, the bottom of the second cylinder 3 is fixedly connected with a bottom plate 4, and the top of the bottom plate 4 is fixedly connected with a riser 5, and the side of the riser 5 close to the housing 1 is provided with two symmetrically arranged track grooves 6. A vertical bar 7 is fixedly installed in the track groove 6, a buffer block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com