Triangular sheet folding assembly

A technology for folding components and triangular pieces, which is applied in the field of sewing machines to prevent burrs from spreading out, ensuring the folding effect and preventing them from falling out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

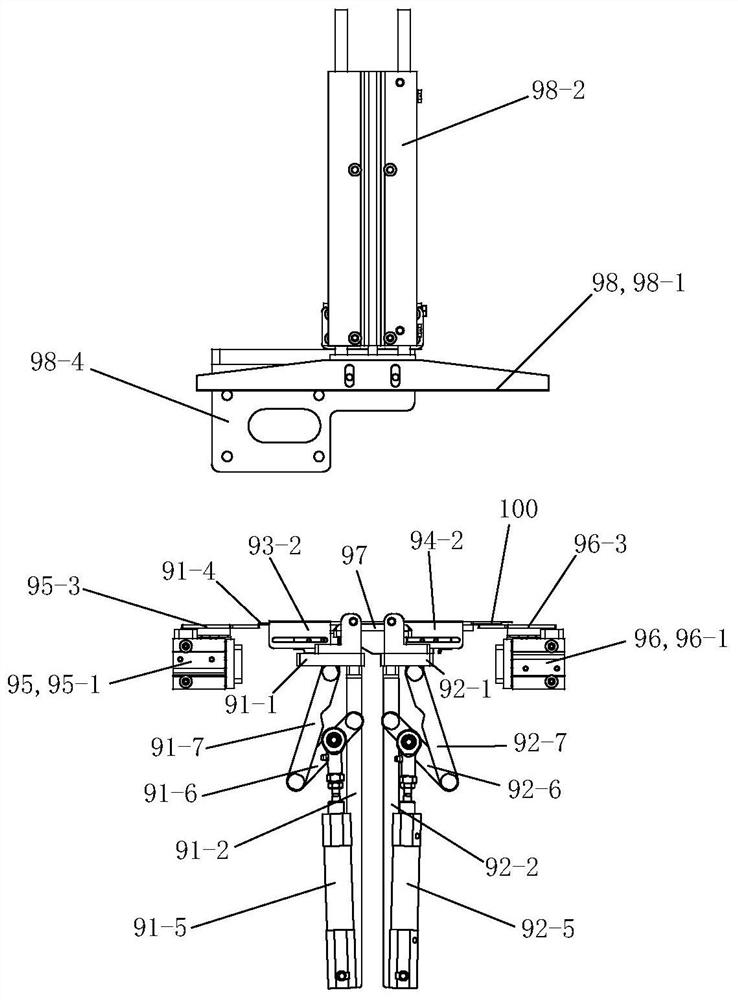

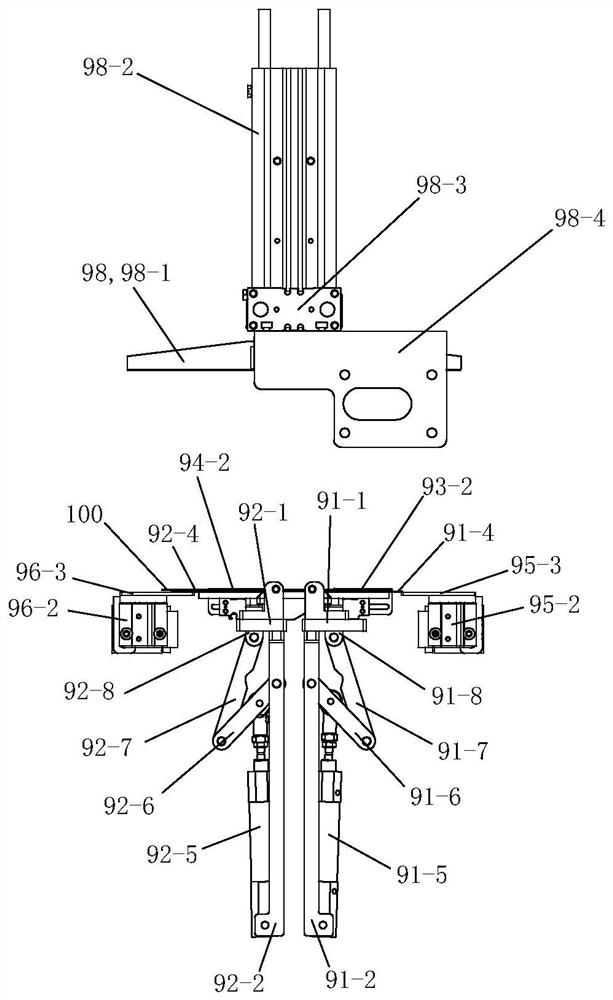

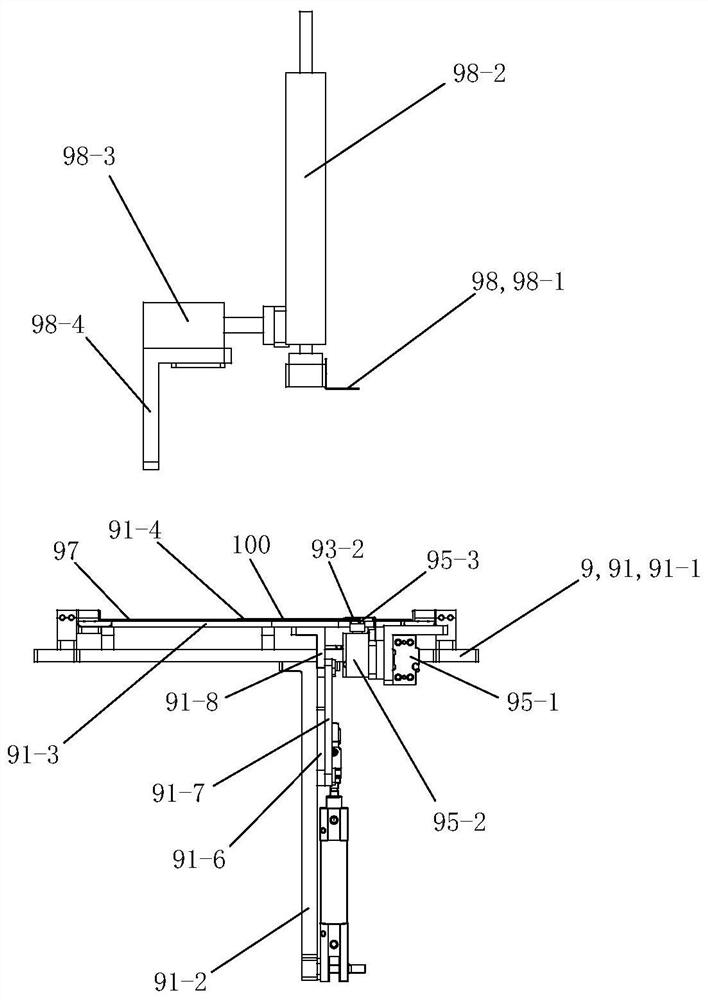

[0044] See Figure 1 to Figure 11 , the gusset folding assembly 9 of the present invention comprises a left side flap device 91, a right side flap device 92, a left side hemming device 93, a right side hemming device 94, a left side platen device 95, a right side platen device 96, Tape positioning plate 97 and upper platen assembly 98.

[0045] See Figure 1 to Figure 5 and Figure 7 to Figure 11 , the left flap device 91 includes a left flap mounting seat 91-1, a left flip cylinder seat 91-2, a left flap frame 91-3, a left flap 91-4, and a left flip cylinder 91- 5. The left first connecting rod 91-6, the left second connecting rod 91-7 and the left third connecting rod 91-8.

[0046] The left flap mounting seat 91-1 is fixedly arranged on the frame of the corresponding tape sewing equipment along the front and back, and is positioned at the lower side of the workbench of the tape sewing equipment. The left turning cylinder seat 91-2 is fixedly arranged on the lower front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com