Metal cutting machine tool

A metal cutting and machine tool technology, which is applied in metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of affecting the use of devices, debris splashing, difficult collection, etc., and achieve the effect of reducing jitter and moving conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

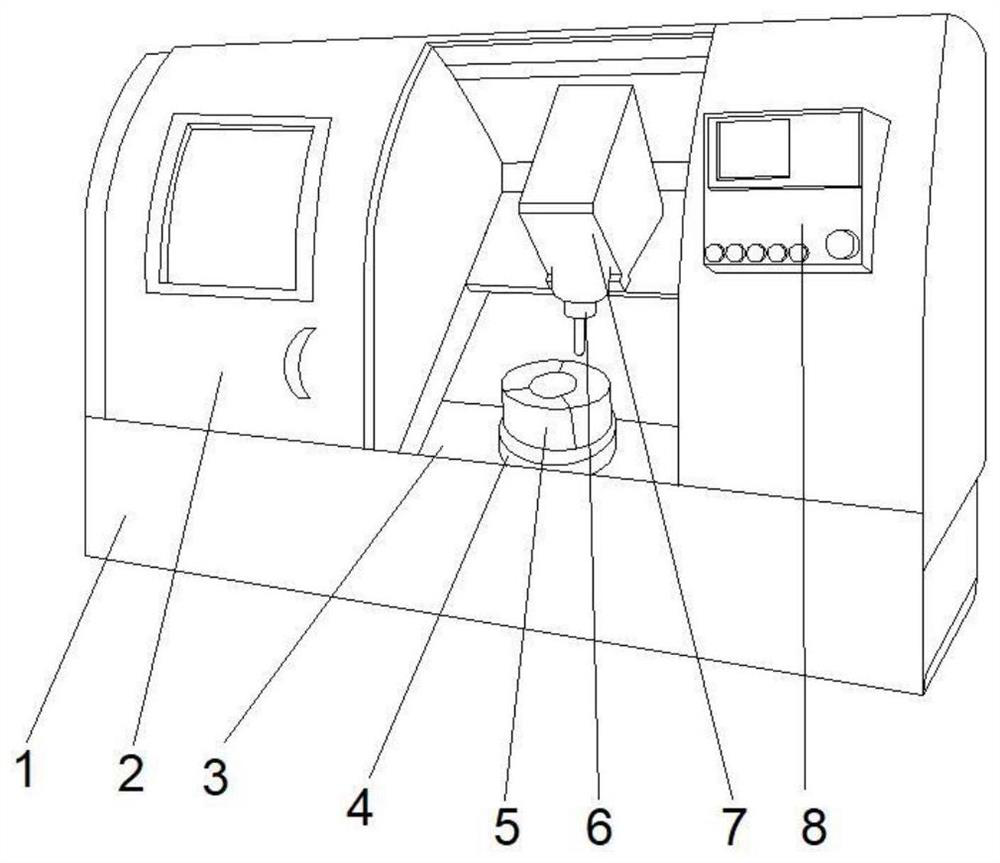

[0035] like Figure 1-2 , a technical solution proposed by the present invention: a metal cutting machine tool, including a main body 1, a working chamber 3 is provided in the middle of the front top of the main body 1, a box door 2 is arranged on the left side of the front top of the main body 1, and the front of the main body 1 The right side of the top is fixedly connected with a controller 8, the top of the inner chamber of the working chamber 3 is provided with a working mechanism 7, the front bottom of the working mechanism 7 is fixedly connected with a cutter 6, and the middle position of the inner chamber bottom of the working chamber 3 is fixedly connected with a communication device 4 , the top of the communication device 4 is fixedly connected with a transition device 5 .

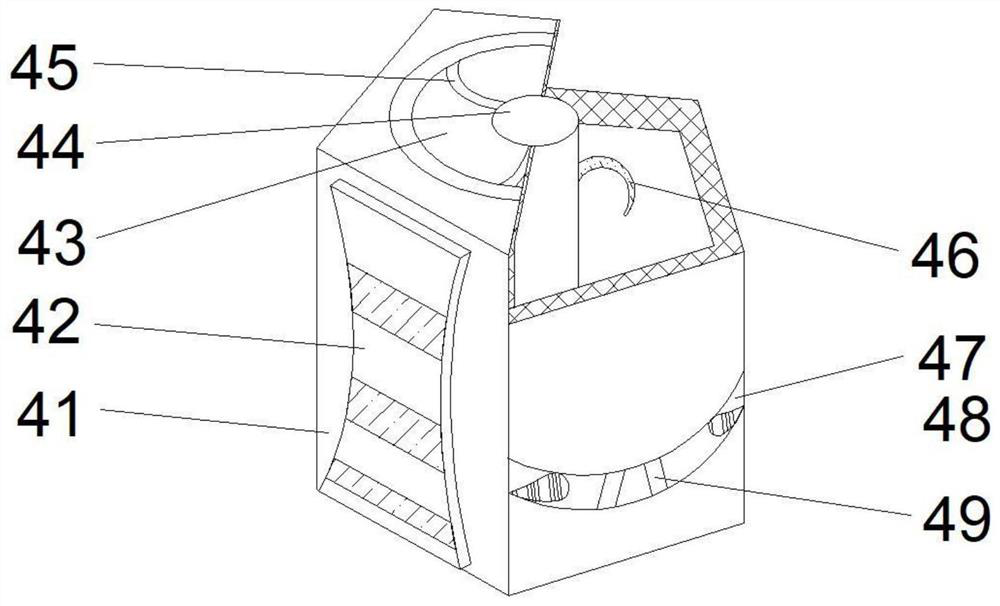

[0036] Wherein, the communication device 4 includes a casing 41, the bottom left side of the front of the casing 41 is fixedly connected with a bottom plate 42, the right side of the front bottom...

Embodiment 2

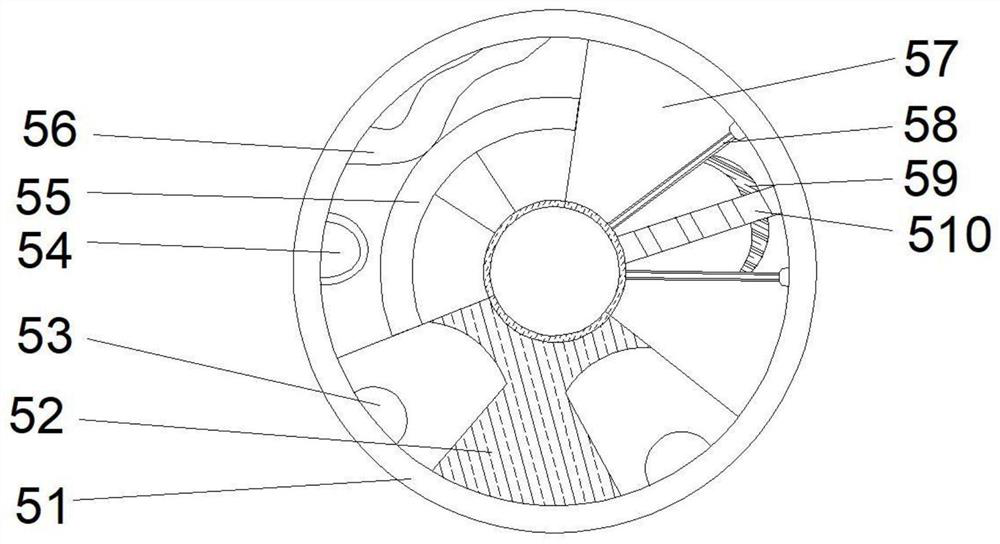

[0039] like Figure 1-3 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the transition device 5 includes an outer frame 51, the bottom of the outer frame 51 is fixedly connected with a top plate 52, and the bottom of the outer frame 51 is located on both sides of the top plate 52. The side is fixedly connected with a communication hole, the middle part of the left side of the outer frame 51 is provided with a rotating ring 55, the position of the outer frame 51 close to the rotating ring 55 is fixedly connected with a wave plate 56, and the position of the outer frame 51 close to the communication hole is fixedly connected with an elastic ball 54 The middle part of the right side of the outer frame 51 is fixedly connected with a connecting fixed rod 510, and the two sides of the connecting fixed rod 510 are fixedly connected with a swing rod 58, and an arc-shaped slider 59 is arranged between the supported swing rod 58 and the connec...

Embodiment 3

[0042] like Figure 1-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the inner walls on both sides of the bottom plate 42 are fixedly connected with fixed plates 424, and the positions between the tops of the fixed plates 424 are fixedly connected with fixed seats 423 A support block 422 is fixedly connected to the top of the fixing seat 423 , and a groove 421 is fixedly connected to the top of the support column 422 .

[0043] Wherein, the front top of the arc block 46 is provided with a turning arc 461, the front middle part of the arc block 46 is provided with a leakage hole 462, and the front bottom of the arc block 46 is fixedly connected with a contact post 464, and the arc block 46 is close to the contact post 464 The position is fixedly connected with fixed teeth 463 .

[0044] Wherein, the top plate 52 includes a connecting frame 522, a guide groove 524 is opened at the middle position of the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com