Autonomous mobile robot system for spot welding of passenger car side wall skin, and working method

A robot system and autonomous movement technology, applied in the direction of manipulators, manufacturing tools, welding equipment, etc., can solve the problems of reducing the labor intensity of operators, welding quality cannot be guaranteed, and the distribution of solder joints is unstable, so as to improve the welding quality of solder joints, The process parameters are stable and controllable, and the solder joints are evenly distributed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

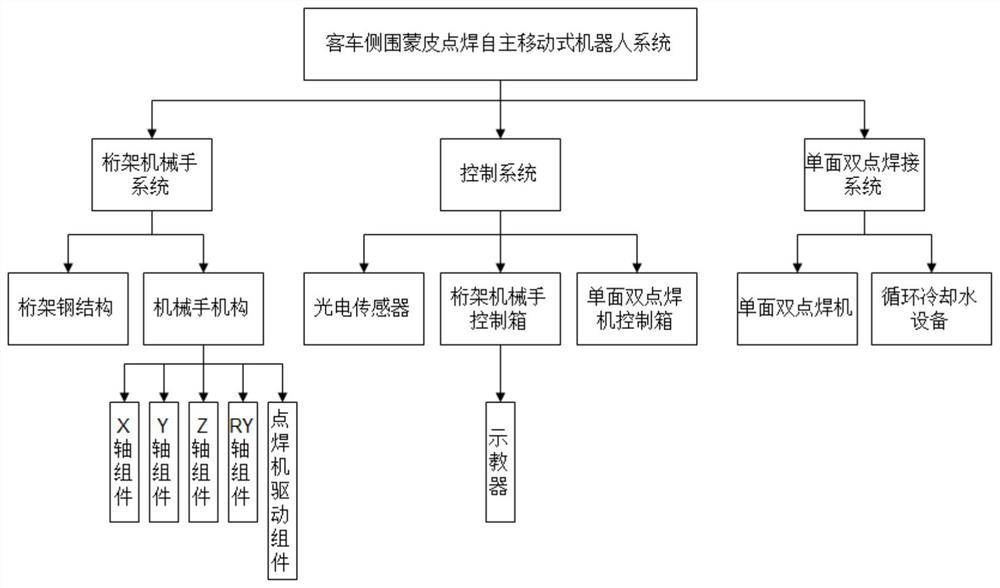

[0044] Such as figure 1 , 2 , 3 and 4, an autonomous mobile robot system for spot welding of passenger car side panels, including a truss manipulator system, a control system and a single-sided double-point welding system, a truss manipulator system, a control system and a single-sided double-point welding system Connected by cables, the single-sided double-spot welding system includes a single-sided double-spot welder 31, and the truss manipulator system includes a truss steel structure 11 and a manipulator mechanism 12 that is arranged on the truss steel structure 11 and is used to move the single-sided double-spot welder 31, The control system includes a photoelectric sensor 21, a teach pendant 22, a truss manipulator control box 23 and a single-sided double-spot welding machine control box 24. The photoelectric sensor 21 is used to measure the deviation of the vehicle's front and rear and height parking positions to realize the automatic positioning function of the device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com