Fuel injector

A technology for fuel injectors and valve components, applied in fuel injection devices, special fuel injection devices, charging systems, etc., can solve problems such as the inconstant closing time of control valves, and achieve the effect of improving the accuracy of injection volume and enhancing swirl flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

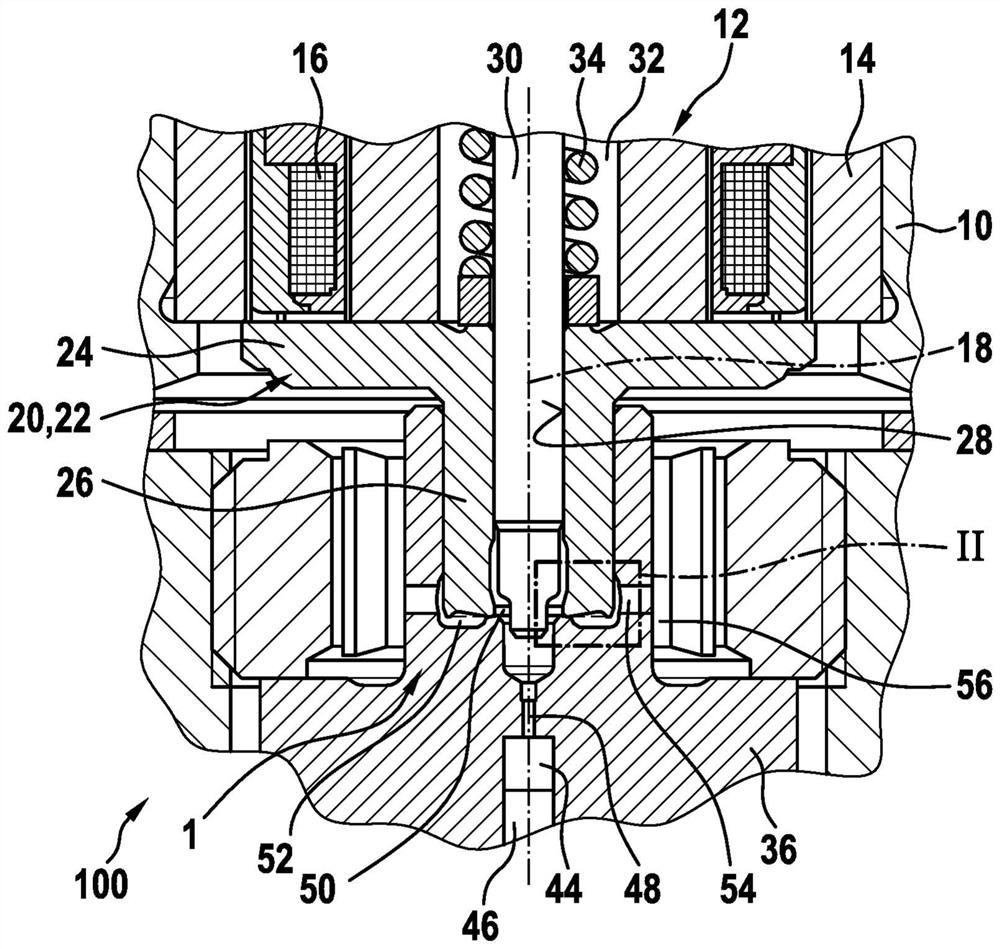

[0024] exist figure 1 The fuel injector 100 shown partially in the center is used to inject fuel into a not shown combustion chamber of a self-igniting internal combustion engine, wherein the system pressure of the fuel stored in the rail can preferably be greater than 2000 bar.

[0025] The fuel injector 100 has an injector housing 10 in which an electromagnet 12 is arranged in a stationary manner. The fuel injector 12 has a magnetic core 14 in which an annular magnetic coil 16 is arranged. When the solenoid coil 16 is energized, a magnetic field is created which attracts the magnetic armature 20 capable of reciprocating on the longitudinal axis 18 and at the same time serves as the valve element 22 and moves it towards the magnetic core 14 until at least indirectly at the core. In the schematic diagram of the drawing, the magnetic armature 20 is shown in a correspondingly de-energized position of the magnetic coil 16 .

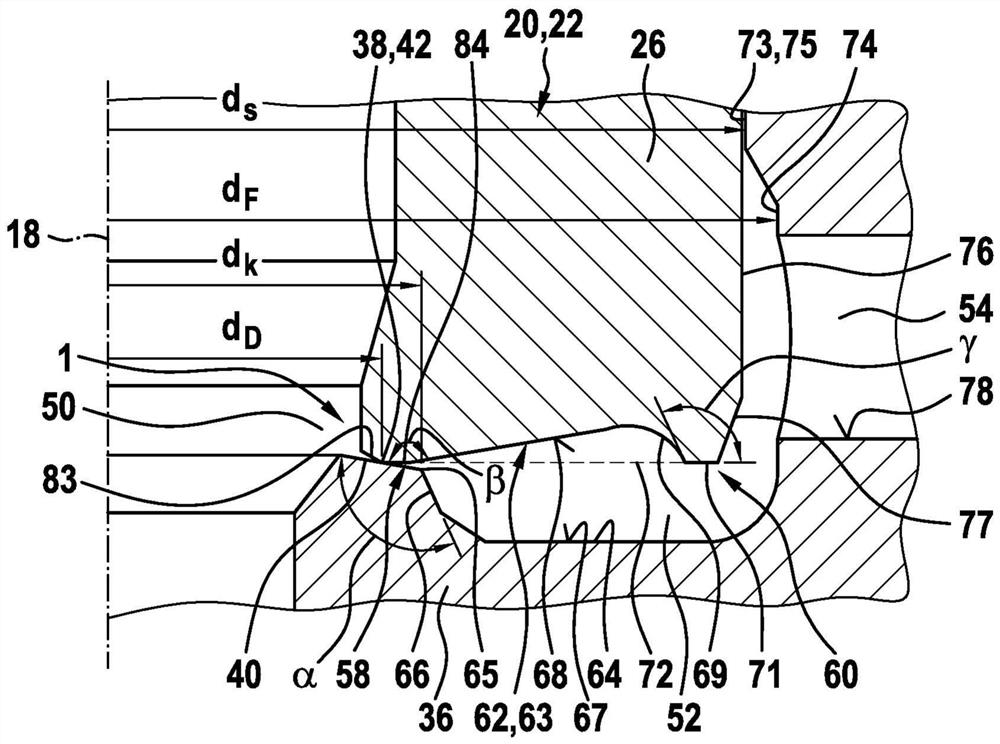

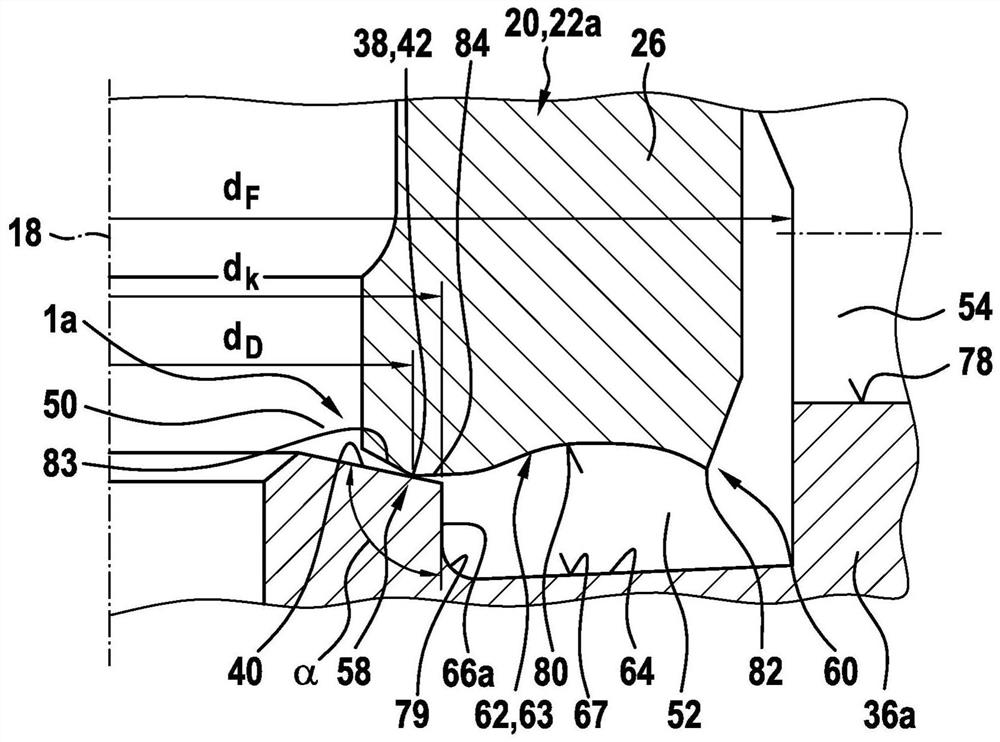

[0026] In the exemplary embodiment, the one-piece a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com