Hollow porous tin dioxide-cuprous oxide-copper or hollow porous tin dioxide-copper integrated lithium battery negative electrode and preparation method thereof

A technology of tin dioxide and cuprous oxide, used in battery electrodes, lithium batteries, secondary batteries, etc., can solve problems such as poor electrical conductivity, capacity decay, and complex processes, and reduce the possibility of pulverization and peeling. , the effect of suppressing the increase in internal resistance and shortening the transmission time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In this example, a method for preparing a hollow porous tin dioxide-cuprous oxide-copper integrated lithium battery negative electrode based on copper foam growth is provided, and the steps are as follows:

[0054] (1) Cut the foamed copper with micron-scale pores into square pieces with a side length of 6mm and press it thinly, then immerse in 1mol / L sulfuric acid solution, let it stand for 12h, remove the oxide layer on the surface of the foamed copper, and then use it successively Ionized water and ethanol were washed under ultrasonic vibration conditions, and vacuum-dried to obtain foamed copper with a thickness of about 1200 μm.

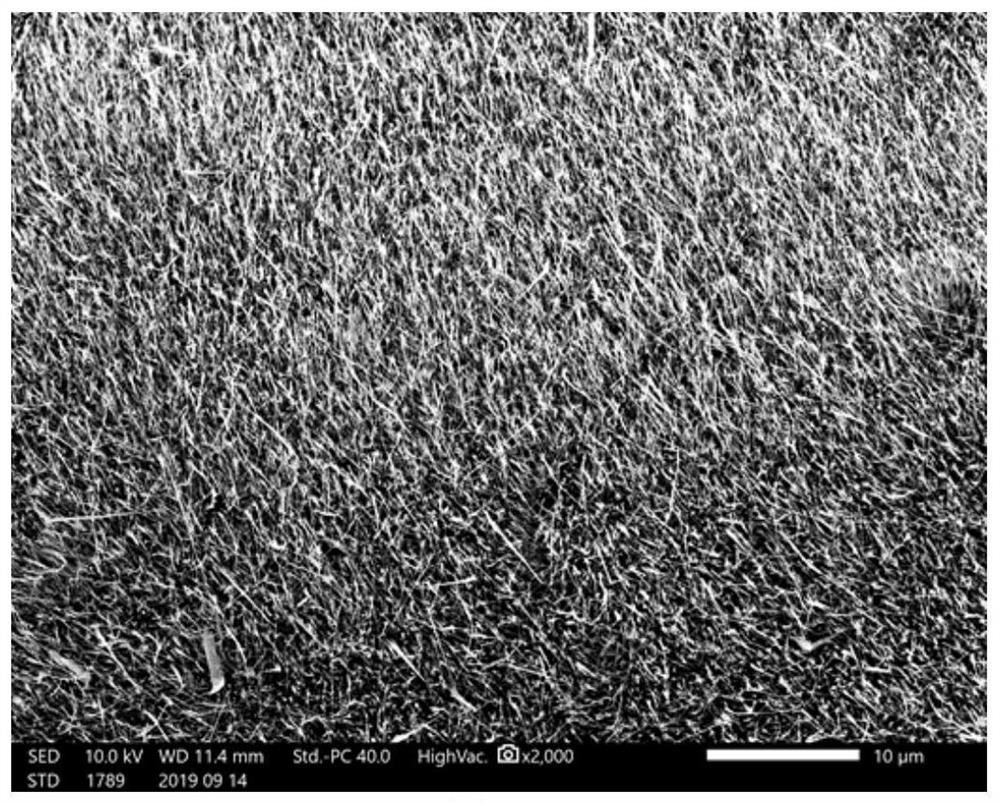

[0055] (2) Place the copper foam treated in step (1) in a tube furnace, raise the temperature to 400°C at a heating rate of 12°C / min in the air atmosphere, and keep it at this temperature for 6h, and the foam copper is partially oxidized into Copper oxide, during the oxidation process, copper oxide nanowires grow on the surface of the foa...

Embodiment 2

[0075] In this example, a method for preparing a hollow porous tin dioxide-cuprous oxide-copper integrated lithium battery negative electrode based on copper foam growth is provided, and the steps are as follows:

[0076] (1) Cut the foamed copper with micron-scale pores into square pieces with a side length of 6mm and press it thinly, then immerse in 1mol / L sulfuric acid solution, let it stand for 12h, remove the oxide layer on the surface of the foamed copper, and then use it successively Ionized water and ethanol were washed under ultrasonic vibration conditions, and vacuum-dried to obtain foamed copper with a thickness of about 2000 μm.

[0077] (2) Place the copper foam treated in step (1) in a tube furnace, raise the temperature to 420°C at a heating rate of 12°C / min in the air atmosphere, and keep it at this temperature for 6h, the foam copper is partially oxidized into Copper oxide, during the oxidation process, copper oxide nanowires grow on the surface of the foamed ...

Embodiment 3

[0085] In this example, a method for preparing a hollow porous tin dioxide-cuprous oxide-copper integrated lithium battery negative electrode based on copper foam growth is provided, and the steps are as follows:

[0086] (1) Cut the foamed copper with micron-scale pores into square pieces with a side length of 6mm and thin it, then immerse it in 1mol / L sulfuric acid solution, let it stand for 10h, remove the oxide layer on the surface of the foamed copper, and then use it successively Ionized water and ethanol were washed under ultrasonic vibration conditions, and vacuum-dried to obtain foamed copper with a thickness of about 1000 μm.

[0087] (2) Place the copper foam treated in step (1) in a tube furnace, raise the temperature to 390°C at a heating rate of 10°C / min in the air atmosphere, and keep it at this temperature for 8 hours. The foamed copper is partially oxidized into Copper oxide, during the oxidation process, copper oxide nanowires grow on the surface of the foame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com