A fracturing well reservoir testing device

A testing device and technology for fracturing wells, which are applied in the directions of measurement, wellbore/well components, and production fluids, etc., can solve problems such as sensors and other electronic accessories that cannot withstand pressure, and sensors and other electronic accessories are damaged, so as to achieve clear division of responsibilities and oil production. The hidden data is accurate and intuitive, and the effect of easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

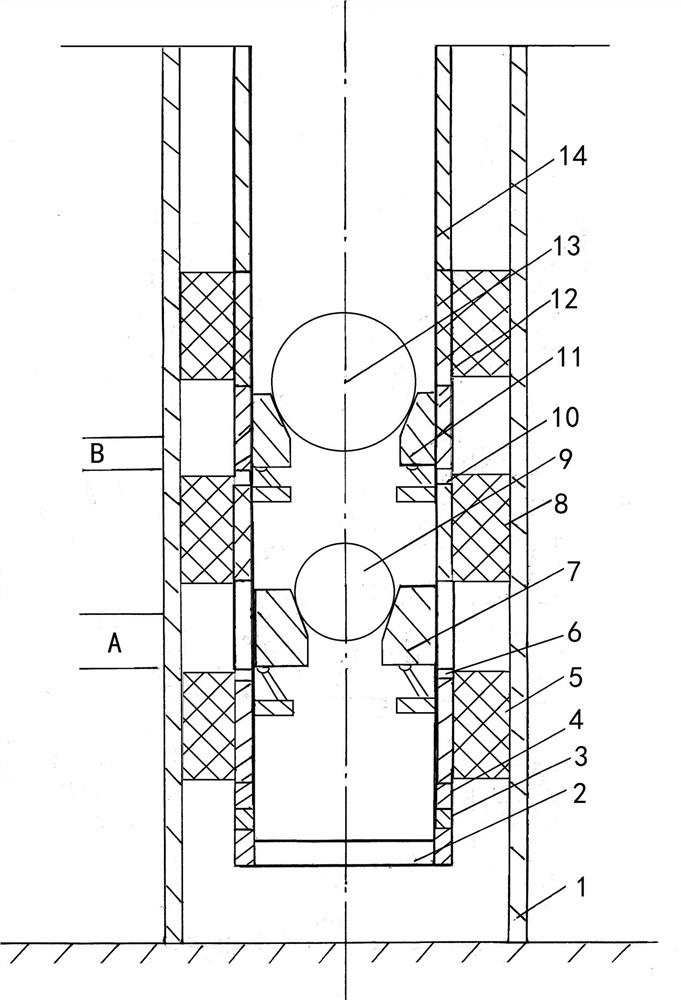

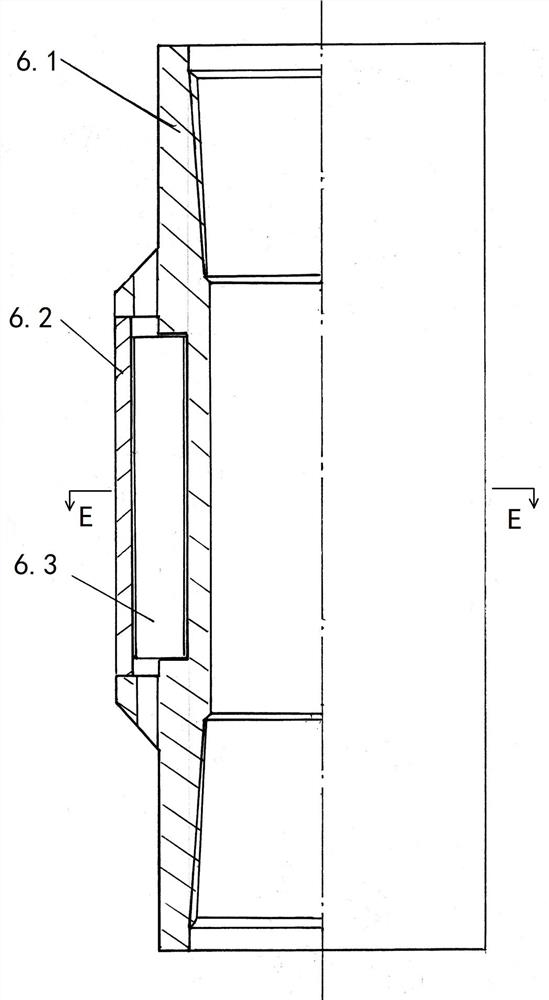

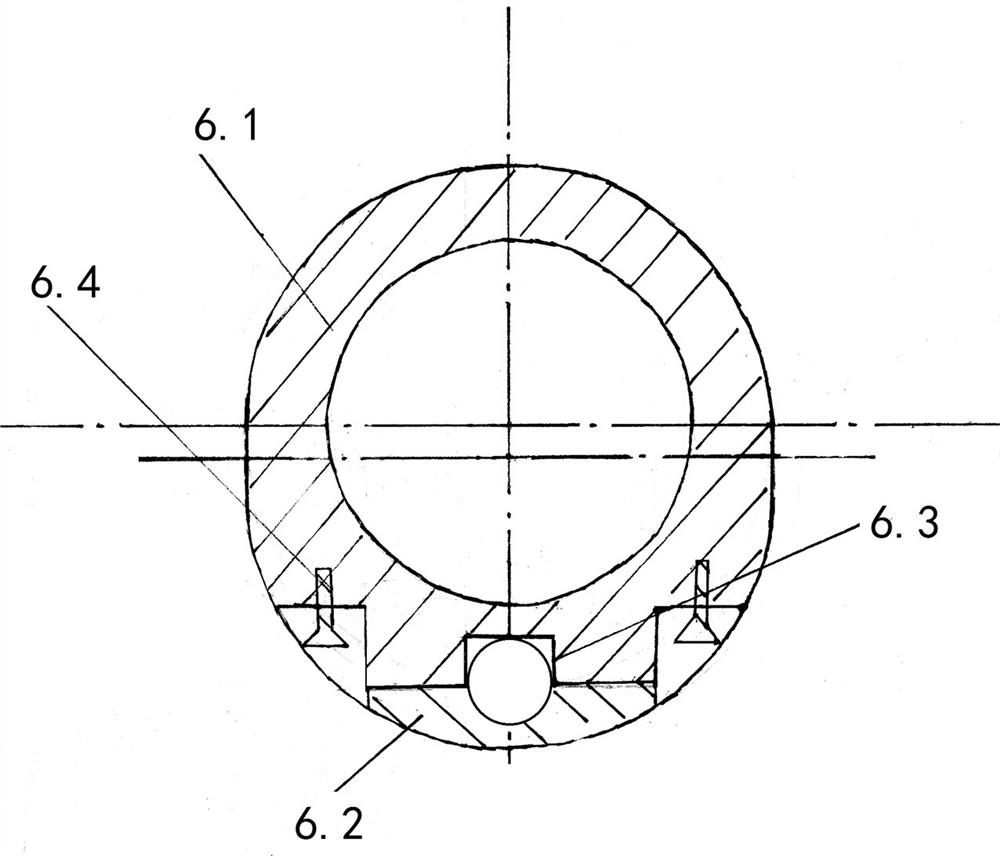

[0027] Example 1, refer to figure 1, a fracturing well reservoir testing device mentioned in the present invention, a second fracturing packer 12, a second fracturing switch 11, a second fracturing tester 10, a first The fracturing packer 8, the first fracturing switch 7, the first fracturing tester 6, the protection packer 5, the buffer tailpipe 4, the well flushing valve 3 and the comparison measuring instrument 2, through the protection packer 5, The first fracturing packer 8 and the second fracturing packer 12 isolate the two oil reservoirs into the first oil reservoir and the second oil reservoir; the second fracturing packer 12 is installed below the second oil reservoir Two fracturing switches 11, the second fracturing tester 10 is installed on the lower side of the second fracturing switch 11, the first fracturing switch 7 is installed under the first fracturing packer 8, the first fracturing switch 7 The first fracturing tester 6 is installed on the lower side; the b...

Embodiment 2

[0049] Embodiment 2, a kind of fracturing well reservoir testing device mentioned in the present invention, differs from Embodiment 1 in that:

[0050] This embodiment can be applied to fracturing wells with more than two oil reservoirs, and a corresponding number of fracturing packers, fracturing switches and fracturing testers can be added according to the number of layers of the oil reservoirs, so as to meet the test of more oil reservoirs Work.

[0051] In addition, the difference from Embodiment 1 is: the number of induction grading ports a17 in the high-voltage test inductor 6.3 can also be set in different numbers according to needs, and the first induction contact a14 can measure more pressure changes, so that the drawn track There are more changes in the graph and the display is more intuitive.

Embodiment 3

[0052] Embodiment 3, a fracturing well reservoir testing device mentioned in the present invention (an oilfield downhole testing device), in which a second fracturing packer 12 and a second fracturing switch are installed below the fracturing string 14 11. The second fracturing tester 10, the first fracturing packer 8, the first fracturing switch 7, the first fracturing tester 6, the protection packer 5, the buffer liner 4, the well flushing valve 3 and Blind plugging, by protecting the packer 5, the first fracturing packer 8 and the second fracturing packer 12, the two oil reservoirs are isolated into the first oil reservoir A and the second oil reservoir B; The second fracturing switch 11 is installed under the second fracturing packer 12, the second fracturing tester 10 is installed under the second fracturing switch 11, and the first fracturing switch 10 is installed under the first fracturing packer 8. The fracturing switch 7, the first fracturing tester 6 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com