New energy lithium battery vacuum packaging device

A technology of vacuum packaging and lithium batteries, which is applied in the direction of packaging material feeding devices, packaging, wrapping paper, etc., can solve the problems of high labor intensity of workers, and achieve the effect of preventing damage and efficient packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

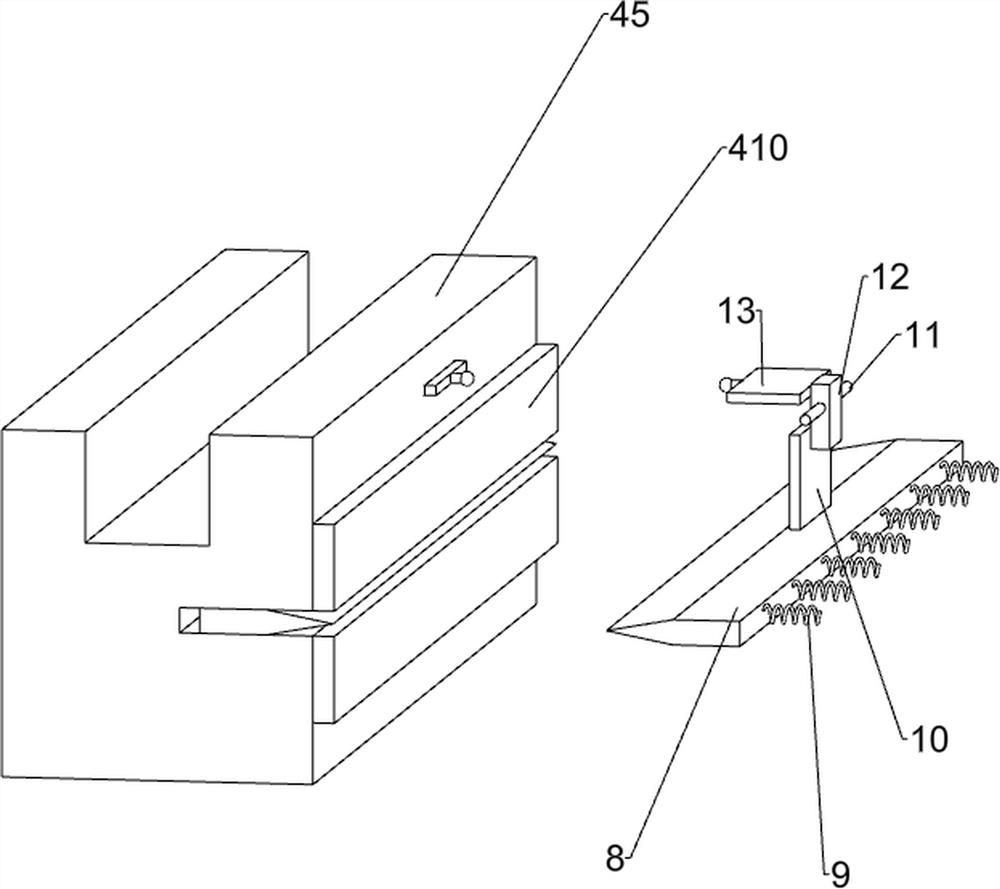

[0030] A new energy lithium battery vacuum packaging device, such as figure 1 , figure 2 and image 3 As shown, it includes a bottom plate 1, a workbench 2, a reciprocating mechanism 3 and a packaging bag sealing mechanism 4, the bottom plate 1 is provided with a workbench 2, the bottom plate 1 is provided with a reciprocating mechanism 3, and the workbench 2 is provided with a packaging bag sealing mechanism 4.

[0031] When people need to use the device, first people will move the part of the bag containing the lithium battery to be sealed between the packaging bag sealing mechanism 4, and then start the reciprocating mechanism 3 and the packaging bag sealing mechanism 4, so that the reciprocating mechanism 3 drives The packaging bag sealing mechanism 4 operates, and then the packaging bag is sealed. After the sealing is completed, the packaging bag sealing mechanism 4 releases the packaging bag, and then people can move the next packaging bag to between the packaging bag...

Embodiment 2

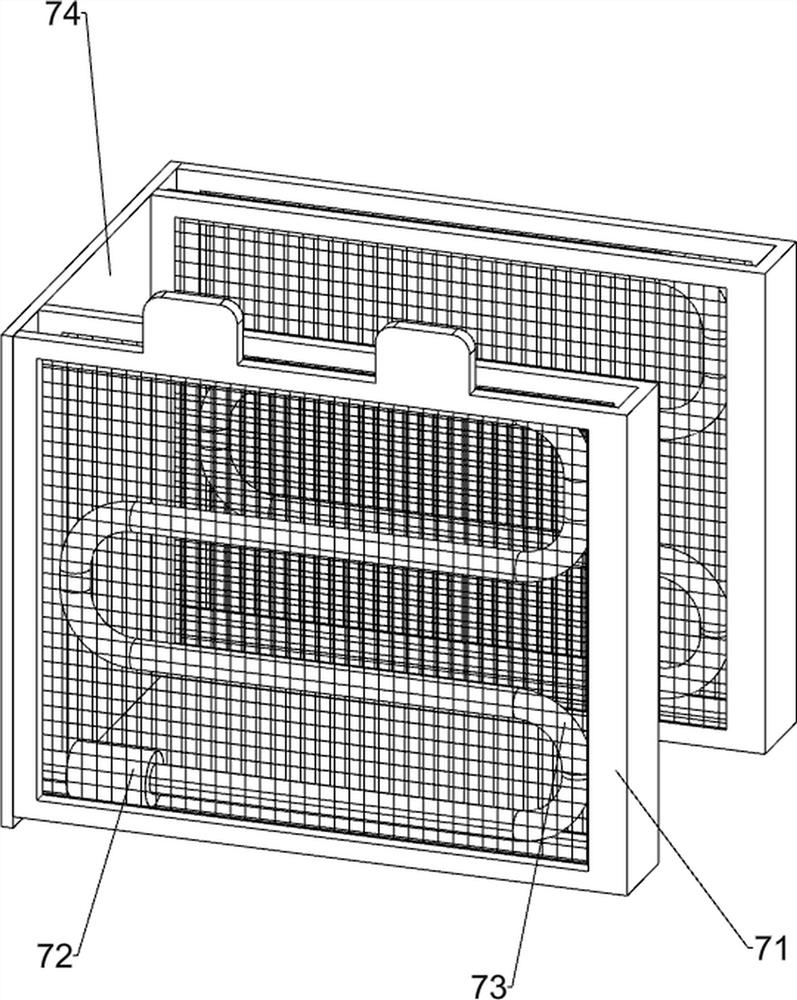

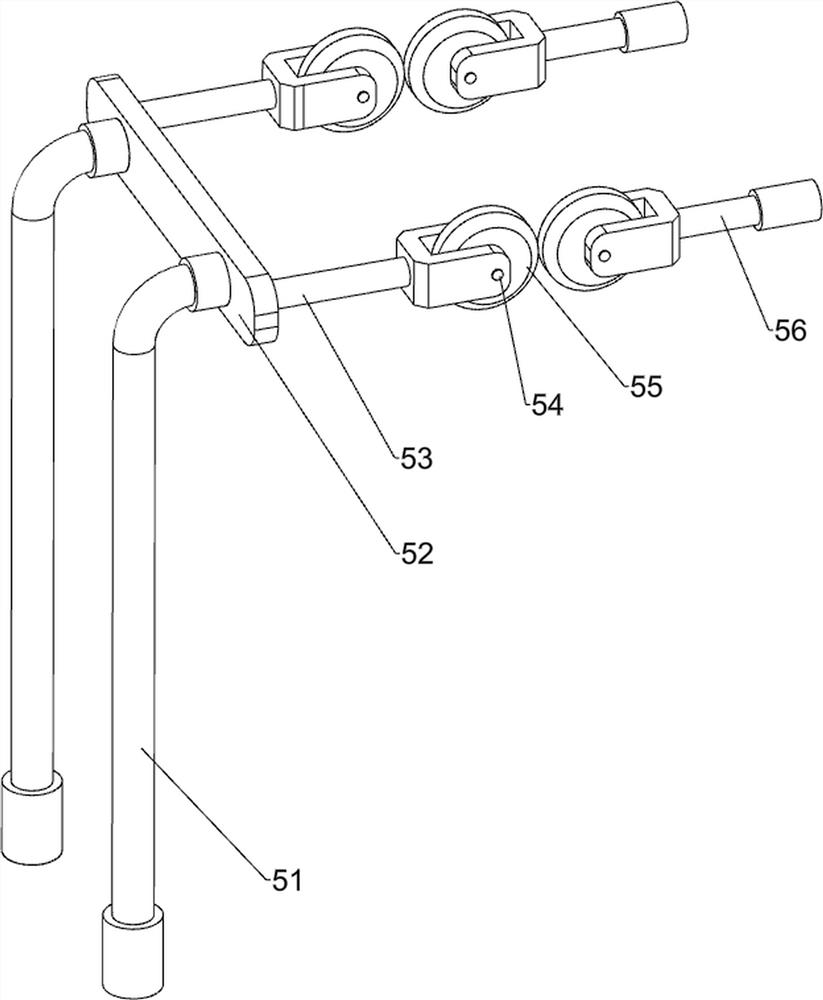

[0036] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 Shown, also comprise intermittent unloading mechanism 6, intermittent unloading mechanism 6 comprises bearing seat 61, second rotating shaft 62, conical missing gear 63, bevel gear 64, the 3rd rotating shaft 65, the first belt transmission device 66, the 2nd Three rotating rods 67, material bearing cylinder 68, the second belt transmission device 69 and circular gear 610, the lower part of the workbench 2 right side is provided with a bearing seat 61, the bearing seat 61 is provided with a second rotating shaft 62, and the first rotating shaft 32 bottom is provided with Conical missing gear 63 is arranged, and the second rotating shaft 62 rear end is provided with bevel gear 64, and bevel gear 64 meshes with conical missing gear 63, and the rotary type of upper left side of workbench 2 is provided with the 3rd rotating shaft 65, and the 3rd rotating shaft 65 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com