Multi-axis milling equipment for workpiece machining

A multi-axis milling and workpiece technology, applied in the field of metal cutting, can solve the problems of inconvenient loading and dismantling of parts, inability to realize automatic locking of parts to be processed, and inability to realize high flexibility, fast and convenient processing, etc., to achieve guaranteed processing Accuracy and consistency, the effect of large space for clamping and dismantling parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Attached below Figure 1-11 The present invention is described in detail below.

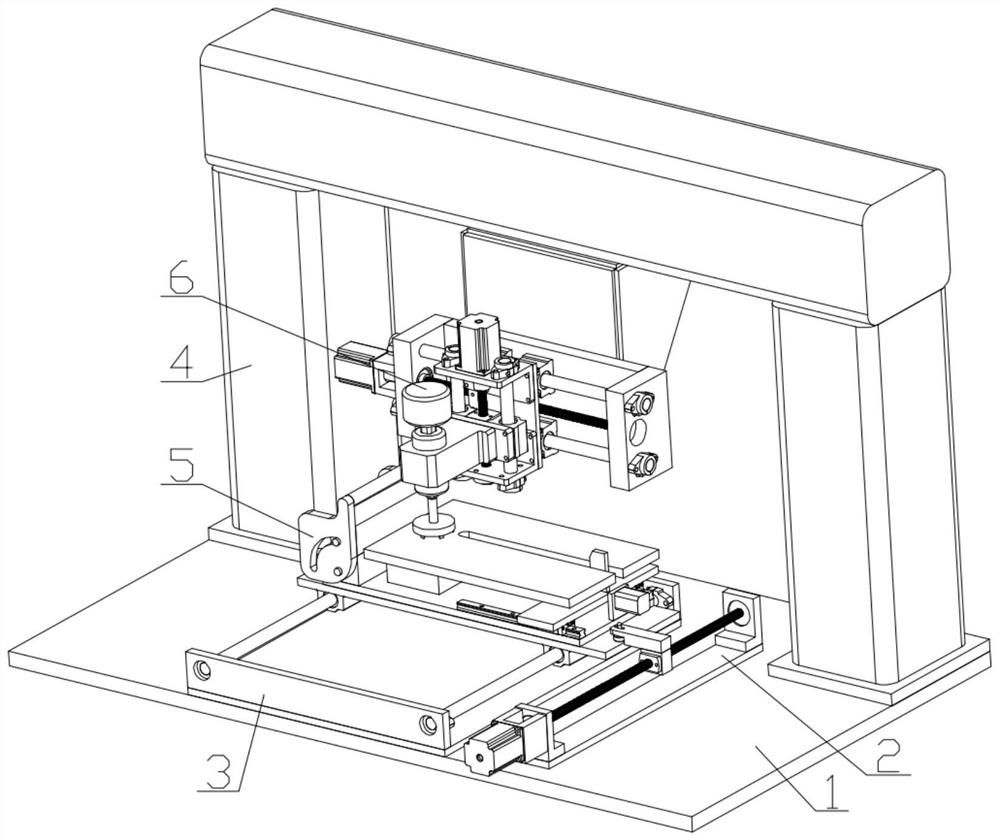

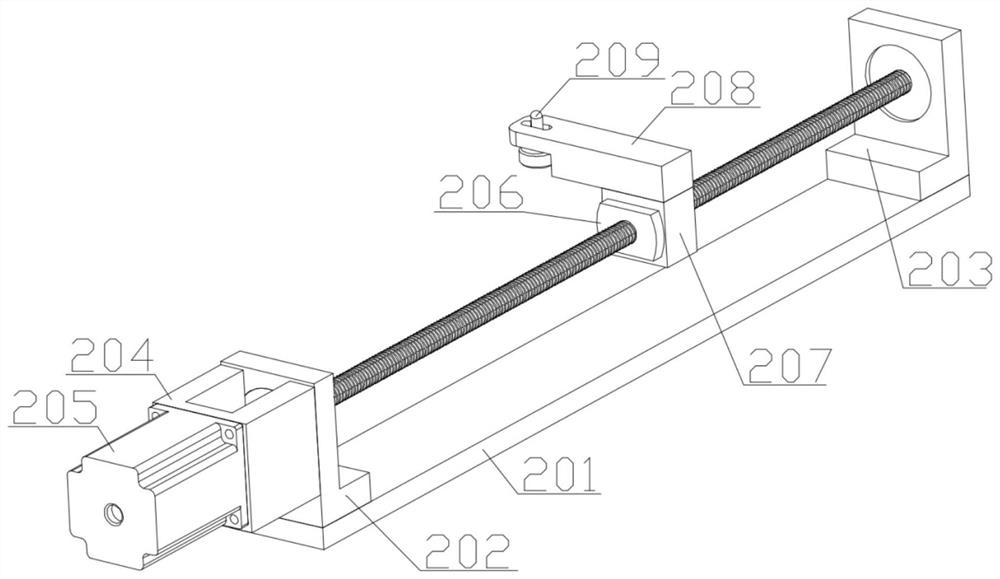

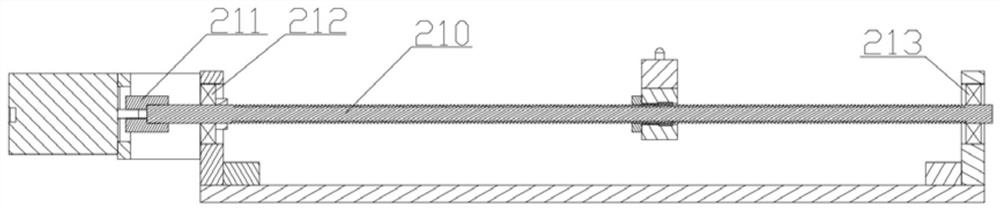

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, a multi-axis milling equipment for workpiece processing includes an equipment base plate 1, the upper mounting surface of the equipment base plate 1 is installed together with the lower mounting surface of the workpiece transporting device base plate 301 in the workpiece transporting device 3, and the workpiece in the workpiece transporting device 3 The front side edge of the transportation device base plate 301 is aligned with the front side edge of the equipment base plate 1, the upper installation surface of the equipment base plate 1 is installed together with the lower installation surface of the gantry frame body frame 401 in the gantry frame device 4, and the equipment base plate 1 The rear side edge of the gantry frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com