kind of la@zr@sio 2 Preparation method of @bentonite composite phosphorus removal adsorbent

A composite adsorption and bentonite technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sewage treatment, etc., can solve the problems of bentonite adsorbents that are not easy to separate and regenerate, limited phosphorus adsorption capacity, and high viscosity of bentonite. Achieve good reusability, easy access, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

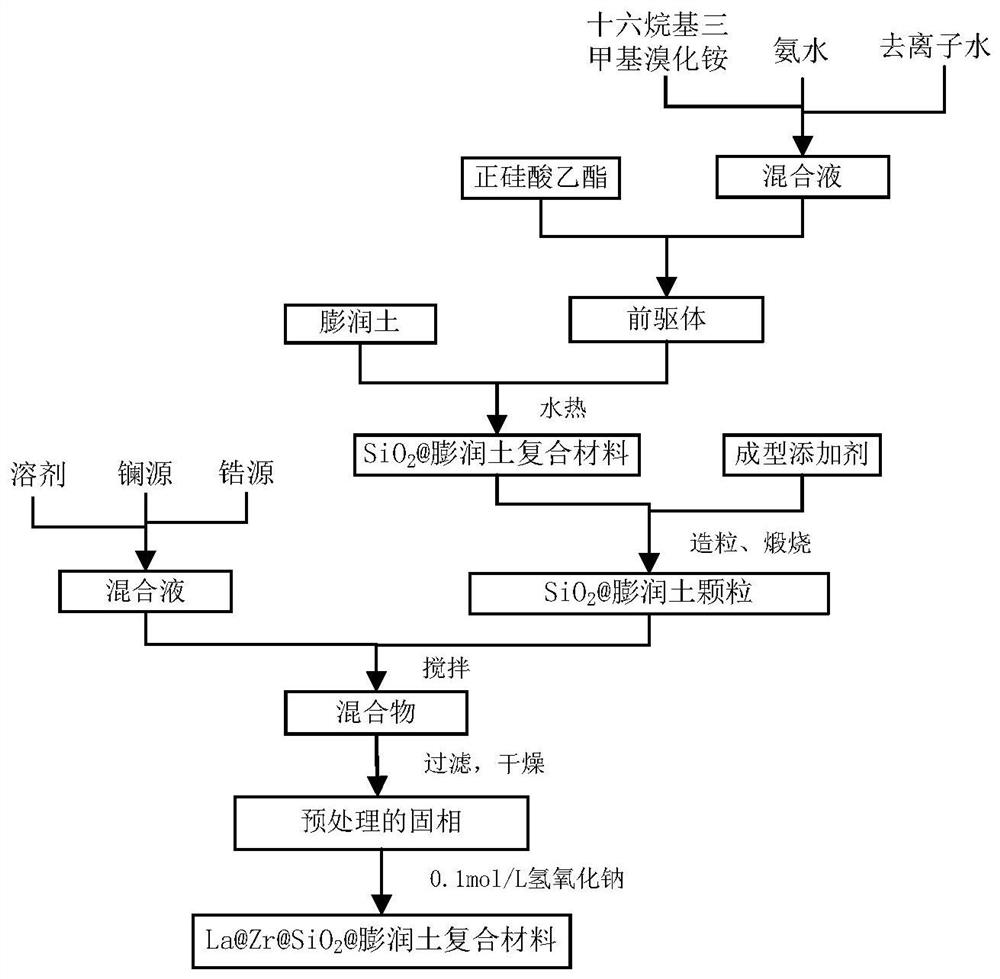

[0032] 1) Mix 20.0 g of cetyltrimethylammonium bromide and 80.0 mL of ammonia water in 1000.0 mL of deionized water, and stir for 1 h to obtain a mixed solution;

[0033] 2) 80.0 mL of ethyl orthosilicate was added to the mixed solution in step 1), and stirred for 3 h;

[0034] 3) Weigh 100.0 g of bentonite, add it to the mixture in step 2), stir at room temperature for 6 hours, transfer it to a round-bottomed flask, and react at a constant temperature in an oil bath at 100°C for 24 hours;

[0035] 4) After suction filtration and washing of the solid-liquid mixture in step 3), the solid phase was dried at a constant temperature of 80° C. for 12 hours, and then mixed with the bentonite raw material powder in a mass ratio of 30:1, and 25 mL of 1% PVA aqueous solution was added and fully mixed, After granulation (the particles are cylindrical with a diameter of 1-2mm and a length of 2-3mm), after drying at a constant temperature of 80°C for 12h, the obtained particles are calcine...

Embodiment 2

[0039] 1) Mix 24.0 g of cetyltrimethylammonium bromide with 100.0 mL of ammonia water in 1200 mL of deionized water, and stir for 1 h;

[0040] 2) 90.0 mL of ethyl orthosilicate will be added to the mixed solution in step 1) and stirred for 4 h;

[0041] 3) Weigh 100.0 g of bentonite, add it to the mixture in step 2), stir at room temperature for 7 hours, transfer it to a round-bottomed flask, and react at a constant temperature in an oil bath at 100°C for 24 hours;

[0042] 4) After suction filtration and washing of the solid-liquid mixture in step 3), the solid phase was dried at a constant temperature of 80° C. for 12 hours, and then mixed with the bentonite raw material powder used in the present invention according to a mass ratio of 30:1, and 20 mL of 1.2% PVA aqueous solution was added. And fully mixed, after granulation (the particles are cylindrical with a diameter of 1-2mm and a length of 2-3mm), after drying at a constant temperature of 80°C for 12h, and calcining i...

Embodiment 3

[0046] 1) Mix 34.0 g of cetyltrimethylammonium bromide with 132.0 mL of ammonia water in 1600 mL of deionized water, and stir for 1 h;

[0047] 2) 120.0 mL of ethyl orthosilicate was added to the mixed solution in step 1) and stirred for 4 h;

[0048] 3) Weigh 100.0 g of bentonite, add it to the mixture in step 2), stir at room temperature for 6 hours, transfer it to a round-bottomed flask, and react at a constant temperature in an oil bath at 100°C for 24 hours;

[0049] 4) After suction filtration and washing of the solid-liquid mixture in step 3), the solid phase was dried at a constant temperature of 80° C. for 12 hours, and then mixed with the bentonite raw material powder used in the present invention according to a mass ratio of 30:1, and 18 mL of 1.3% PVA aqueous solution was added. And fully mixed, after granulation (the particles are cylindrical with a diameter of 1-2mm and a length of 2-3mm), after drying at a constant temperature of 80°C for 12h, and calcining in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com