Rotary electric machine stator and rotary electric machine provided with same

A technology for rotating electrical machines and stators, which is used in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of thermal damage to insulating films, easy reduction of stator coil manufacturing yields, and reduced electrical insulation, and achieves low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0057] (rotating motor)

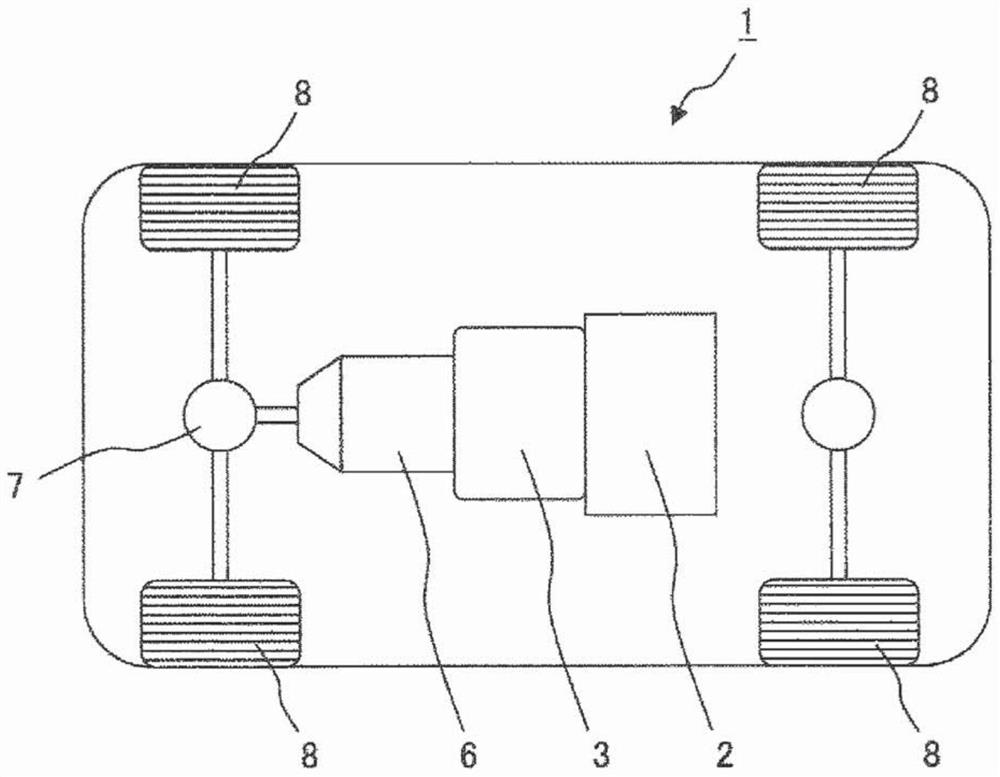

[0058] figure 1 It is an example of a block diagram of a hybrid electric vehicle equipped with a rotary electric machine according to the present invention. like figure 1 As shown, a vehicle 1 of a hybrid electric vehicle is equipped with an engine 2 and a rotating electric machine 3 as power sources of a vehicle drive system. The rotational torque generated by the engine 2 and the rotary electric machine 3 is transmitted to wheels (drive wheels 8 ) via a transmission 6 (for example, a continuously variable transmission, a stepped transmission) and a differential gear 7 . The rotary electric machine 3 is usually installed between the engine 2 and the transmission 6 or mounted on the transmission 6 . Therefore, the rotary electric machine 3 is required to be smaller and higher in output in order to minimize the space occupied in the vehicle 1 and to increase the driving force.

[0059] In addition, although figure 1 Not shown in , but it is also p...

no. 2 Embodiment approach

[0104] Compared with 1st Embodiment, 2nd Embodiment differs only in the form of the exposed part of the conductor wire which forms the welding part of a stator coil, and is the same in all other things. Therefore, only the form of the welded portion and the exposed portion of the conductor wire will be described.

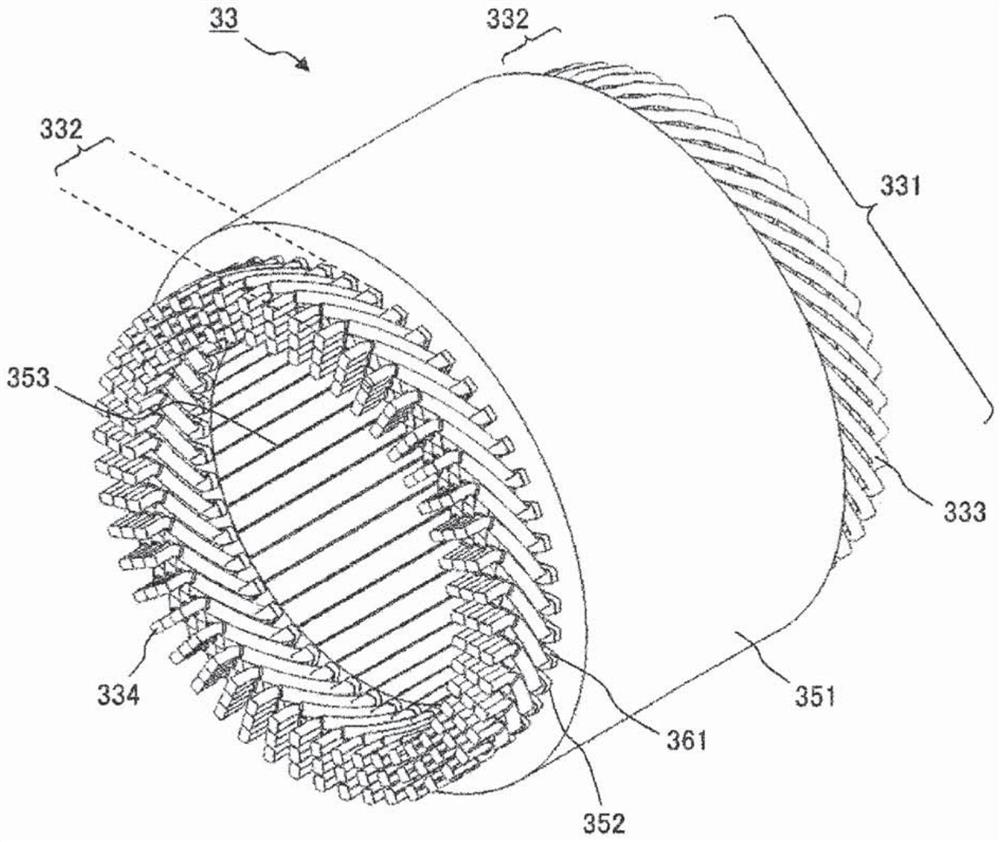

[0105] Figure 9 It is an enlarged schematic side view showing an example of a welded portion of a stator coil in the second embodiment. like Figure 9 As shown, the welding part 334' of the stator coil 331' according to the second embodiment is characterized in that only one conductor wire exposed part 343' of the paired segment conductors 333' constituting the welding part 334' has a root 343b , the transfer portion 343t and the junction portion 343j , the junction portion 343j is offset by a displacement x of “2±0.4 times” the thickness of the insulating film 342 in the radial direction relative to the root portion 343b . The shift amount x is more preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com