Efficient dust-removing and heat-dissipating device in computer host

A heat dissipation device and computer technology, applied in the field of computers, can solve problems such as uneven heat dissipation, poor heat dissipation effect, and shortened lifespan, and achieve good heat dissipation effect, good user experience, and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

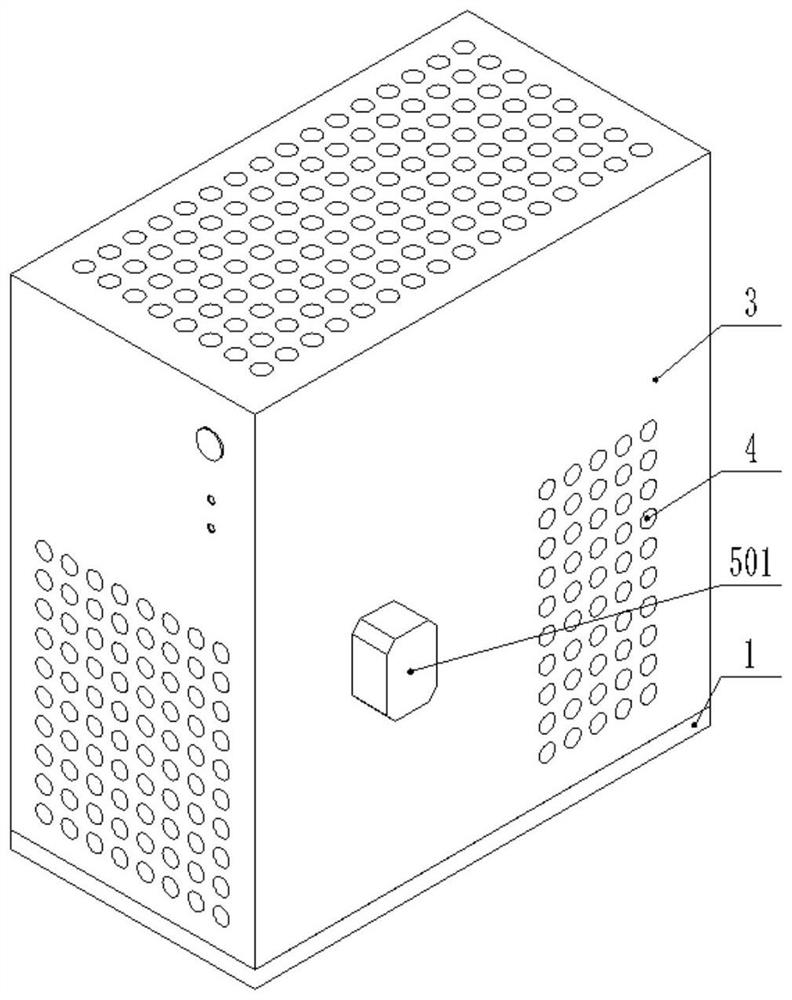

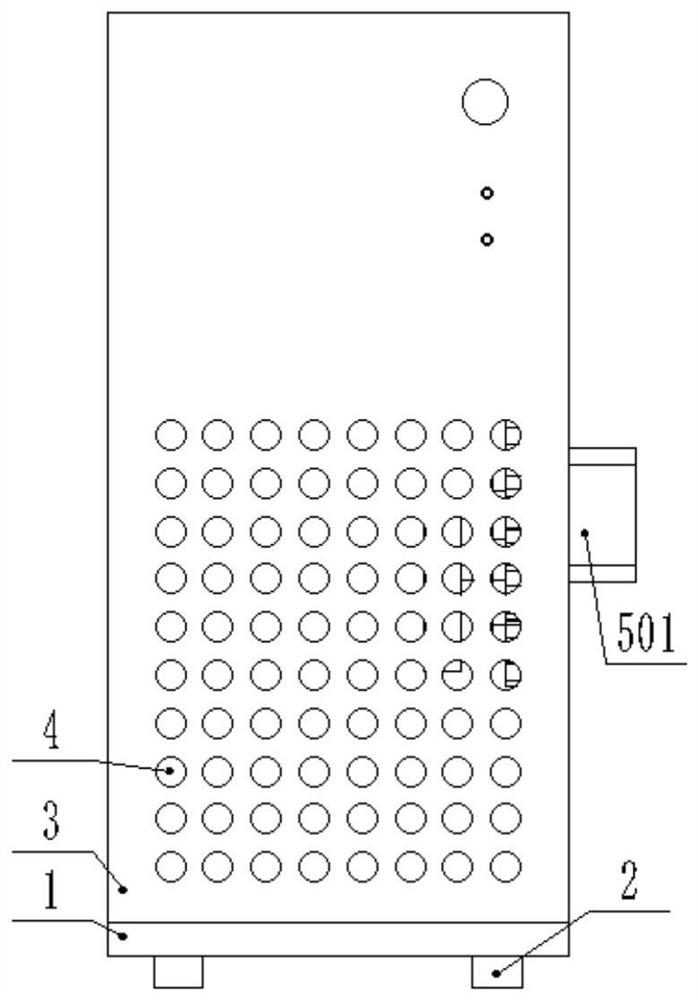

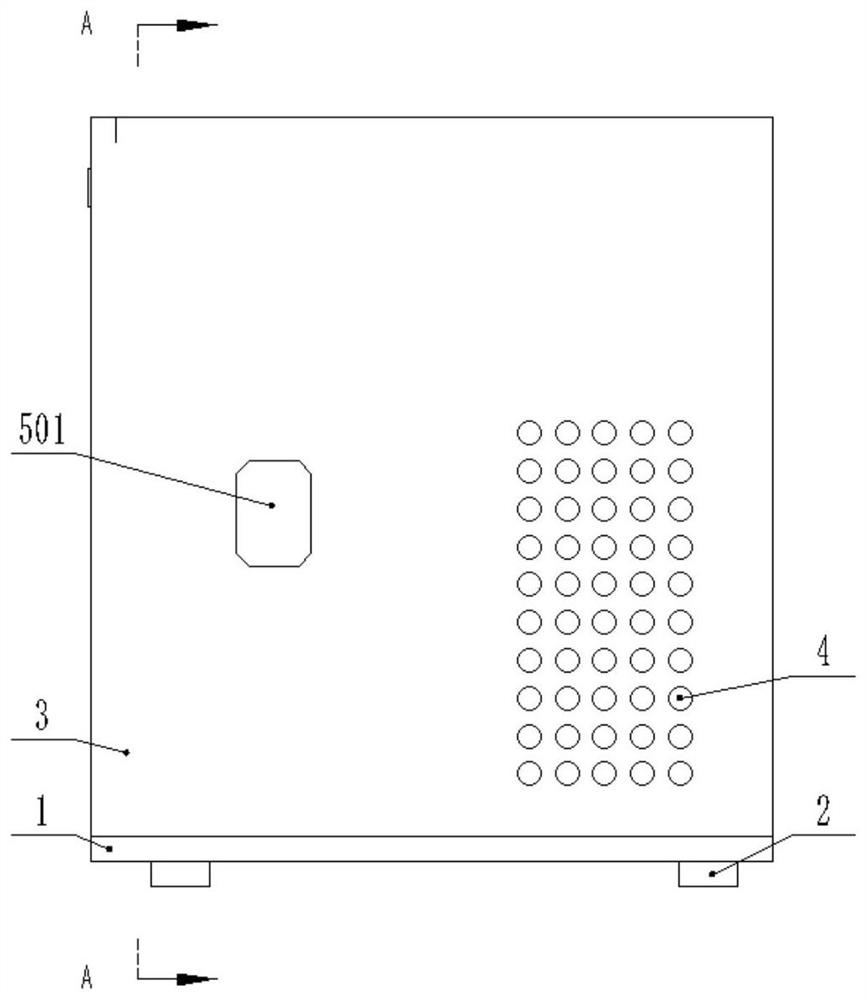

[0024] Example 1: Please refer to Figure 1-5 , a high-efficiency dust-removing and heat-dissipating device inside a computer mainframe, comprising a base 1, a cushion block 2 is fixedly connected to the bottom of the base 1, front, rear, left, and right, and a box body 3 is fixedly connected to the top of the base 1, and the surface of the box body 3 is provided with Cooling hole 4;

[0025] The front end of the outer middle part of the right wall of the box body 3 is fixedly connected with the driving mechanism 5. When in use, the driving motor 501 and the rotating motor 802 are turned on, and the output end of the driving motor 501 rotates to drive the rotation of the motor rotating shaft 502, thereby making the rotating plate 503 surround the motor rotating shaft 502 rotates, and then drives the driven gear 903 to rotate around the motor shaft 502 while rotating, and then makes the rotating gear 702 meshed with the transmission gear 701 rotate around the motor shaft 502 wh...

Embodiment 2

[0037] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the material of the dust removal plate 704 is activated carbon.

[0038] The working principle of the present invention is: when in use, the driving motor 501 and the rotating motor 802 are turned on, the output end of the driving motor 501 rotates and then drives the rotation of the motor shaft 502, and then the rotation plate 503 rotates around the motor shaft 502, and then drives the driven gear 903 Rotate around the motor rotating shaft 502 while rotating, and then make the rotating gear 702 meshed with the transmission gear 701 rotate around the motor rotating shaft 502 while rotating, and then drive the rotating rod 703 to rotate, and then make the dust removal plate 704 fixedly connected with it to rotate automatically Rotate around the motor shaft 502 at the same time, and then remove the dust inside the box body 3; the output end of the rotating motor 802 rotates and then drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com