Intelligent wire checking instrument based on coding communication

A technology of coding communication and calibration instrument, which is applied in the field of calibration instrument, can solve the problems of easily scattered terminals and cables, inconvenient retracting and unloading of the calibration instrument, inconvenient carrying operation, etc., so as to improve the use effect and facilitate viewing The display screen and the operation of the intelligent calibration instrument facilitate the effect of wiring operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

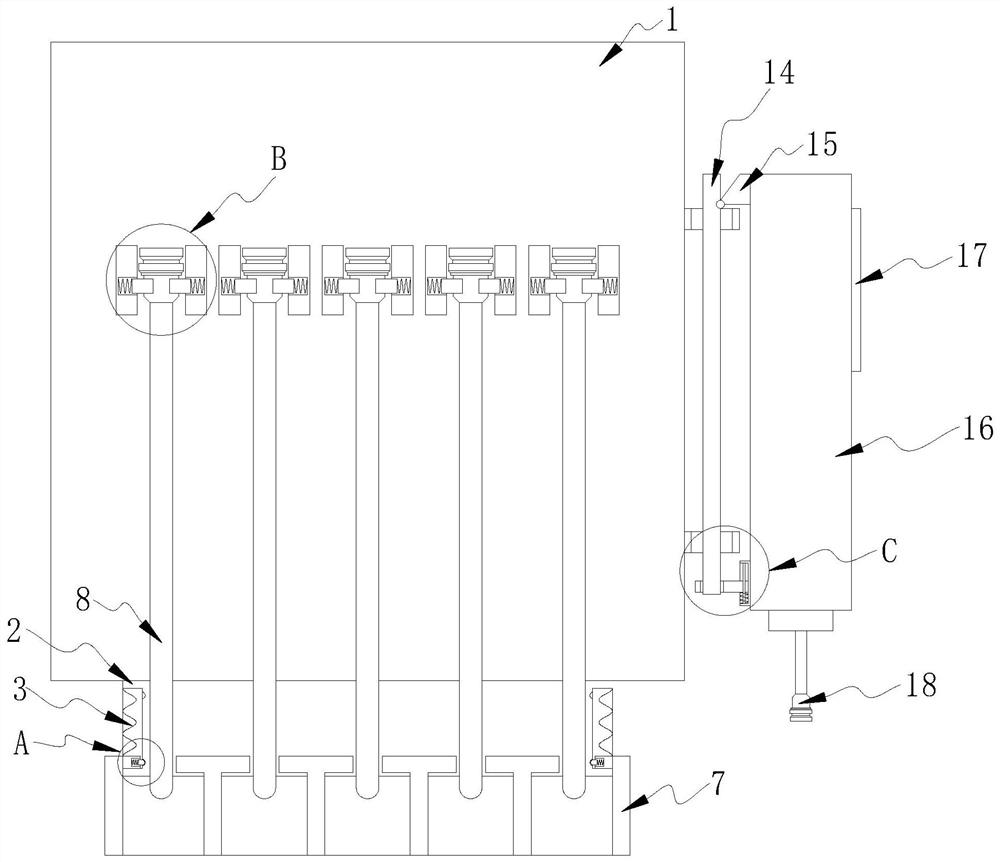

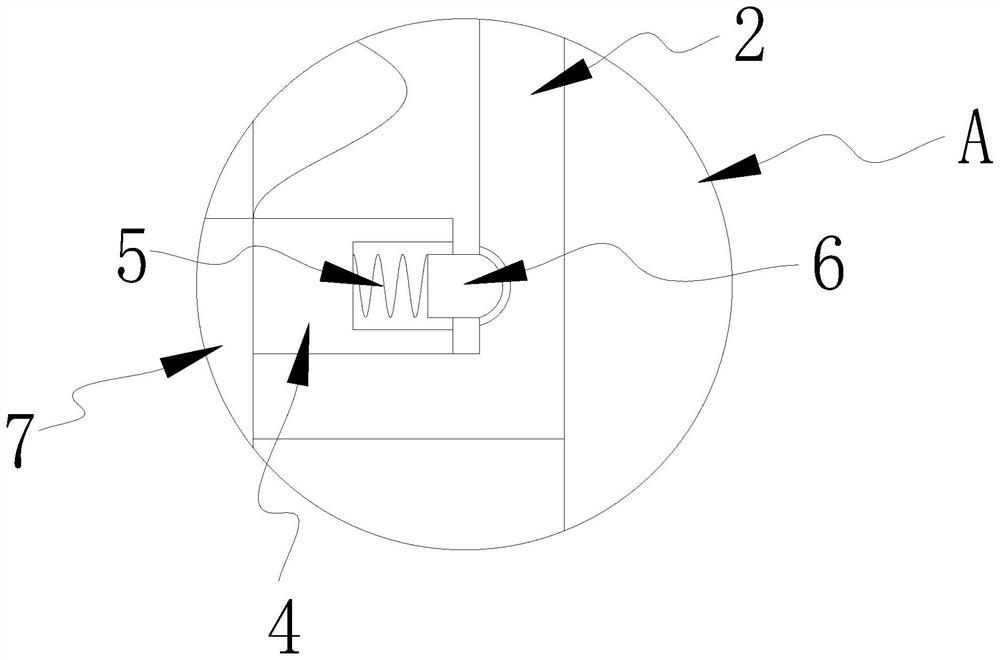

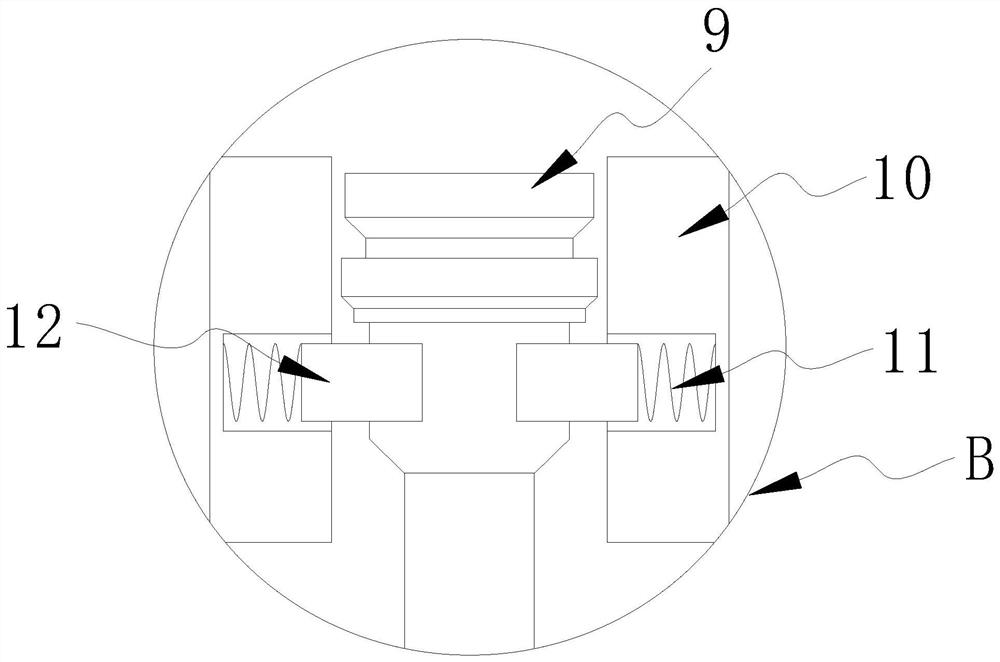

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 shown;

[0035] figure 1 It is a structural schematic diagram of the whole of the present invention;

[0036] figure 2 for the present invention figure 1 Schematic diagram of the structure at A;

[0037] image 3 for the present invention figure 1 Schematic diagram of the structure at B;

[0038] Figure 4 for the present invention figure 1 Schematic diagram of the structure at C;

[0039] Figure 5 It is a schematic diagram of the installation structure of the protective case in the present invention;

[0040] Figure 6 It is a schematic diagram of the installation structure of the terminal in the present invention;

[0041] Figure 7 It is an assembly drawing of the support rod in the present invention.

[0042]An intelligent line calibration instrument based on coded communication, comprising a detection box 1, the bottom end of the detection box 1 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com