Lipophilic microbial nutritional agent

A nutrient and lipophilic technology, applied in the field of lipophilic microbial nutrient, can solve the problems affecting microbial growth, petroleum hydrocarbon utilization ability and loss, and achieve the effect of increasing bacterial growth, improving alkane degradation rate, and high sample loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

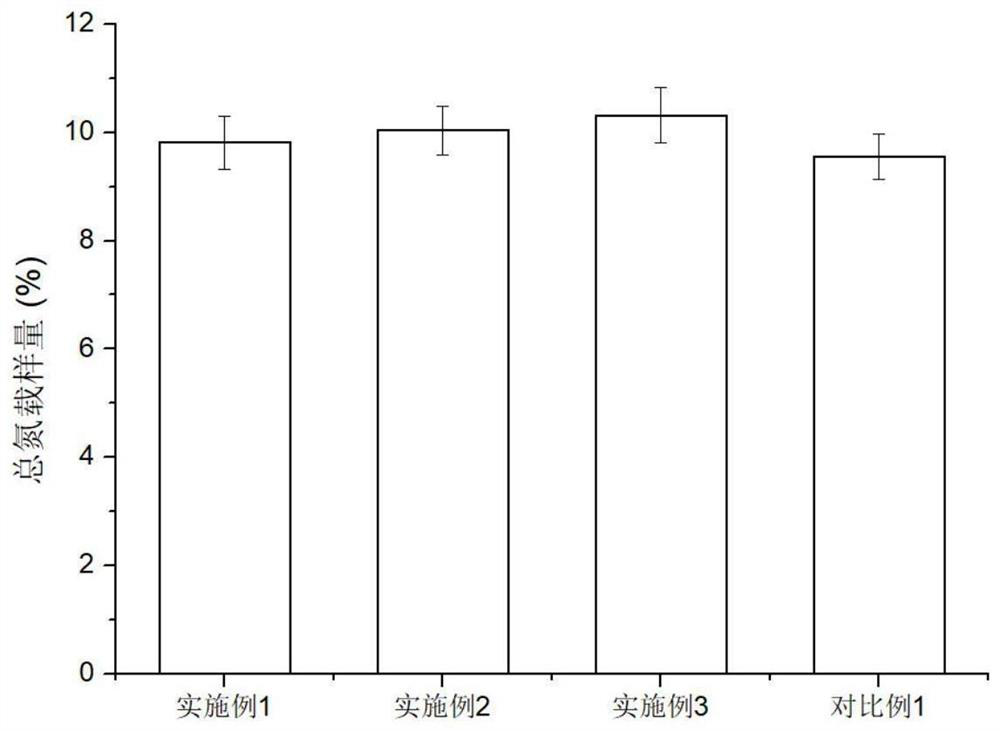

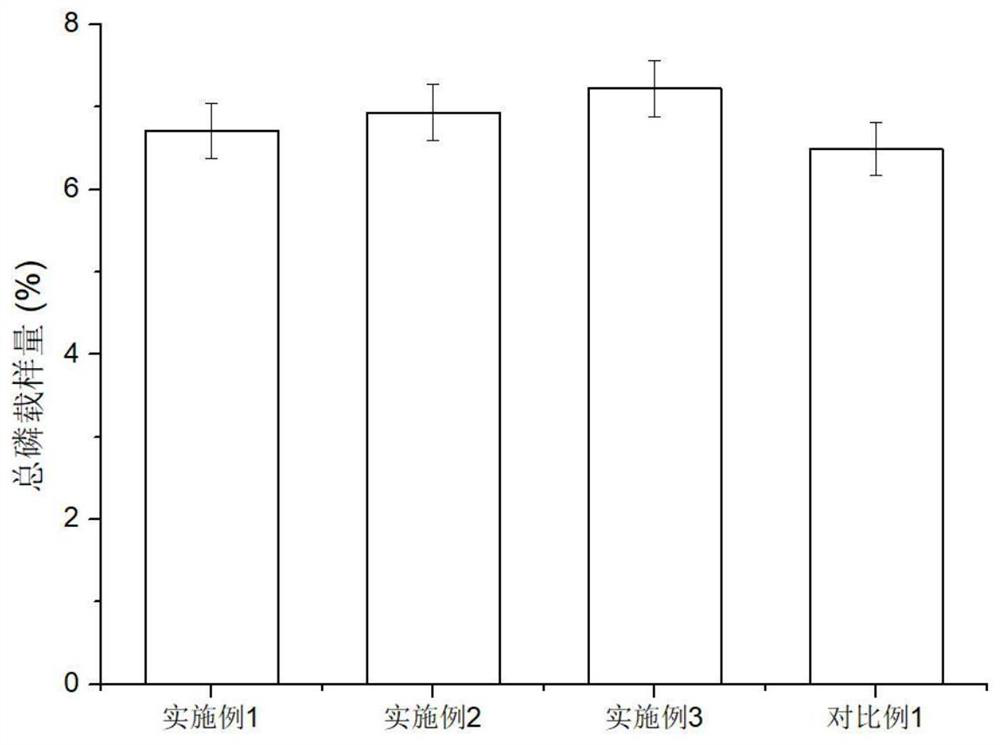

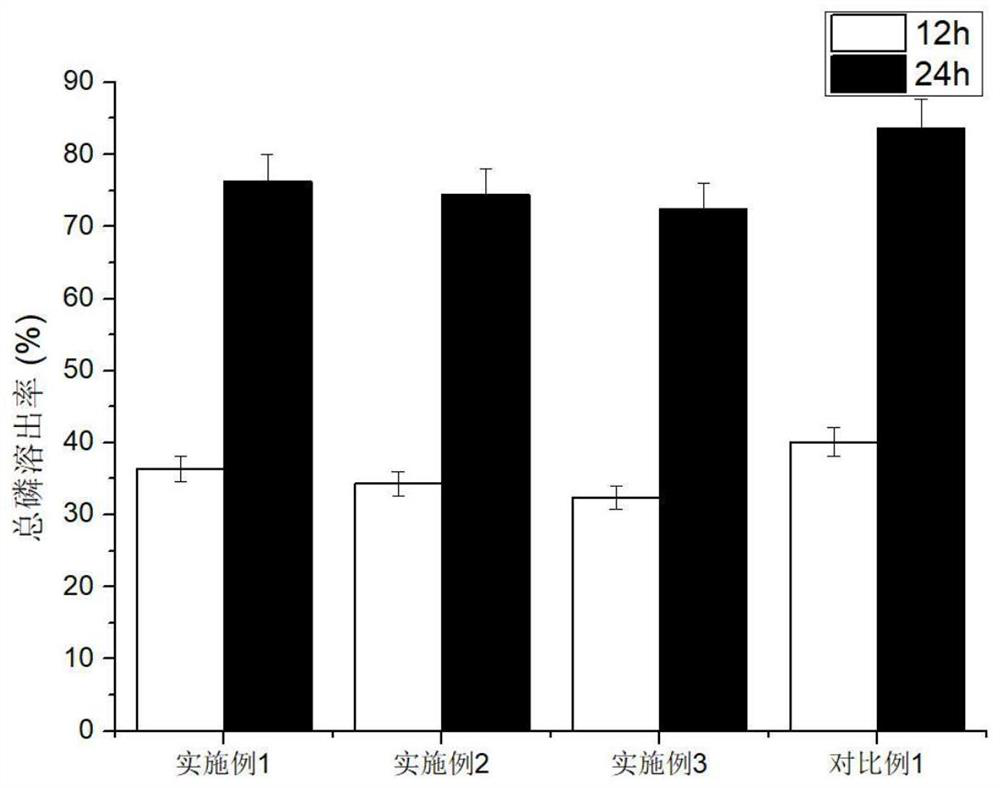

Embodiment 1

[0042] A preparation method of lipophilic microbial nutrient,

[0043] Add sodium alginate and additives to the ethanol solution, stir at 25°C for 20 minutes to obtain a wall material solution, add nutrients to the wall material solution, stir and mix thoroughly for 30 minutes to obtain a nutrient-wall material mixed solution, and mix the nutrients- The wall material mixed solution is added to the paraffin liquid containing the active agent, fully stirred and mixed for 20 minutes, added to the calcium chloride solution for fixation, fully stirred and mixed for 40 minutes, centrifuged at 25°C, washed with acetone, dried and solidified to obtain lipophilic microbial nutrition agent; the mass fraction of ethanol solution is 30wt%, and the addition amount of sodium alginate is 2wt% of ethanol solution, and additive comprises nancandle xyloside and rhamnoside, and the addition amount of nancandle xyloside is sodium alginate 15wt%, the rhamnosyl ester is 2-O-rhamnopyranosyl-rhamnopy...

Embodiment 2

[0045] A preparation method of lipophilic microbial nutrient,

[0046]Add sodium alginate and additives to the ethanol solution, stir at 25°C for 20 minutes to obtain a wall material solution, add nutrients to the wall material solution, stir and mix thoroughly for 30 minutes to obtain a nutrient-wall material mixed solution, and mix the nutrients- The wall material mixed solution is added to the paraffin liquid containing the active agent, fully stirred and mixed for 20 minutes, added to the calcium chloride solution for fixation, fully stirred and mixed for 40 minutes, centrifuged at 25°C, washed with acetone, dried and solidified to obtain lipophilic microbial nutrition agent; the mass fraction of ethanol solution is 30wt%, and the addition amount of sodium alginate is 2wt% of ethanol solution, and additive comprises nancandle xyloside and rhamnoside, and the addition amount of nancandle xyloside is sodium alginate 25wt%, the rhamnosyl ester is 2-O-rhamnopyranosyl-rhamnopyr...

Embodiment 3

[0048] A preparation method of lipophilic microbial nutrient,

[0049] Add sodium alginate and additives to the ethanol solution, stir at 25°C for 20 minutes to obtain a wall material solution, add nutrients to the wall material solution, stir and mix thoroughly for 30 minutes to obtain a nutrient-wall material mixed solution, and mix the nutrients- The wall material mixed solution is added to the paraffin liquid containing the active agent, fully stirred and mixed for 20 minutes, added to the calcium chloride solution for fixation, fully stirred and mixed for 40 minutes, centrifuged at 25°C, washed with acetone, dried and solidified to obtain lipophilic microbial nutrition agent; the mass fraction of ethanol solution is 30wt%, and the addition amount of sodium alginate is 2wt% of ethanol solution, and additive comprises nancandle xyloside and rhamnoside, and the addition amount of nancandle xyloside is sodium alginate 35wt%, the rhamnosyl ester is 2-O-rhamnopyranosyl-rhamnopy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com