Full-automatic hanging scaffold mechanism

A fully automatic, hanging tray technology, applied in thin material handling, conveying filamentous materials, transportation and packaging, etc., can solve the problems of large space, easy to scratch the surface of the wrapped wire, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

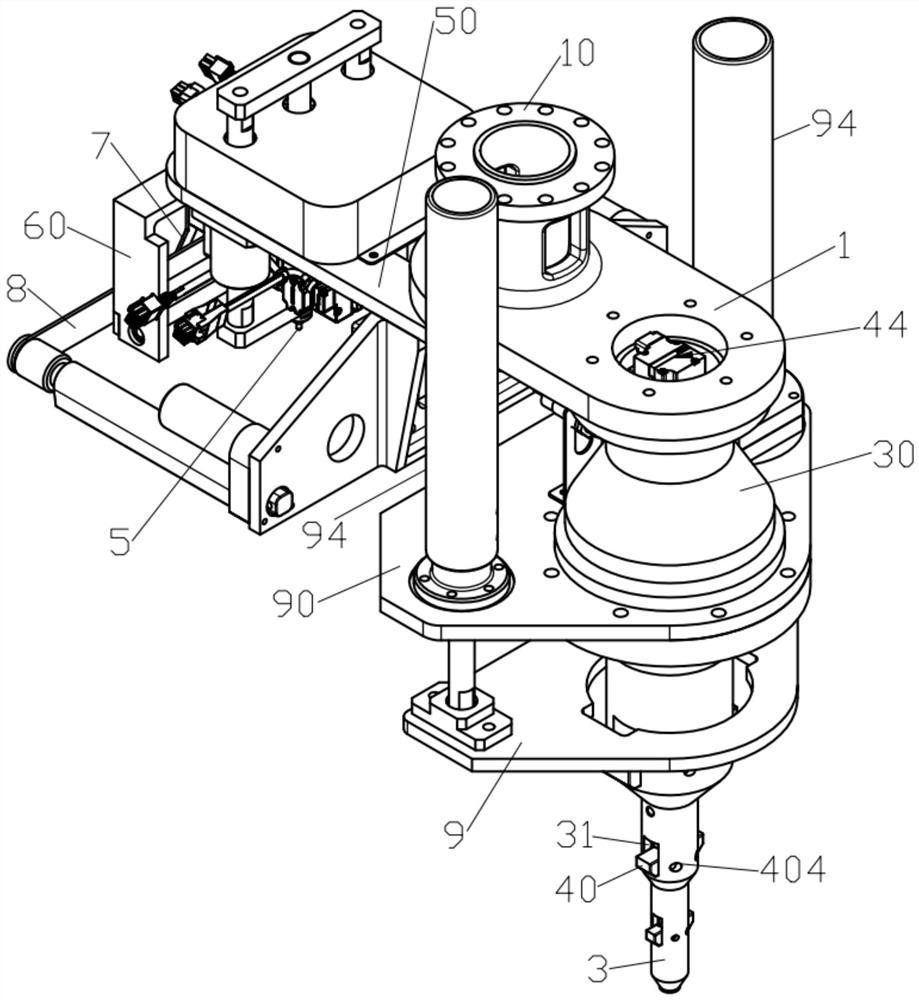

[0049] Such as Figures 1 to 4 As shown, a fully automatic suspension mechanism according to an embodiment of the present invention includes a base 1 , a thread end processing device disposed at one end of the base 1 , and a hoisting device disposed at the other end of the base 1 .

[0050] A manipulator positioning ring 10 is installed on the base 1, and the manipulator positioning ring 10 is used to connect the manipulator, so as to realize the cooperation between the fully automatic suspension mechanism and other equipment parts.

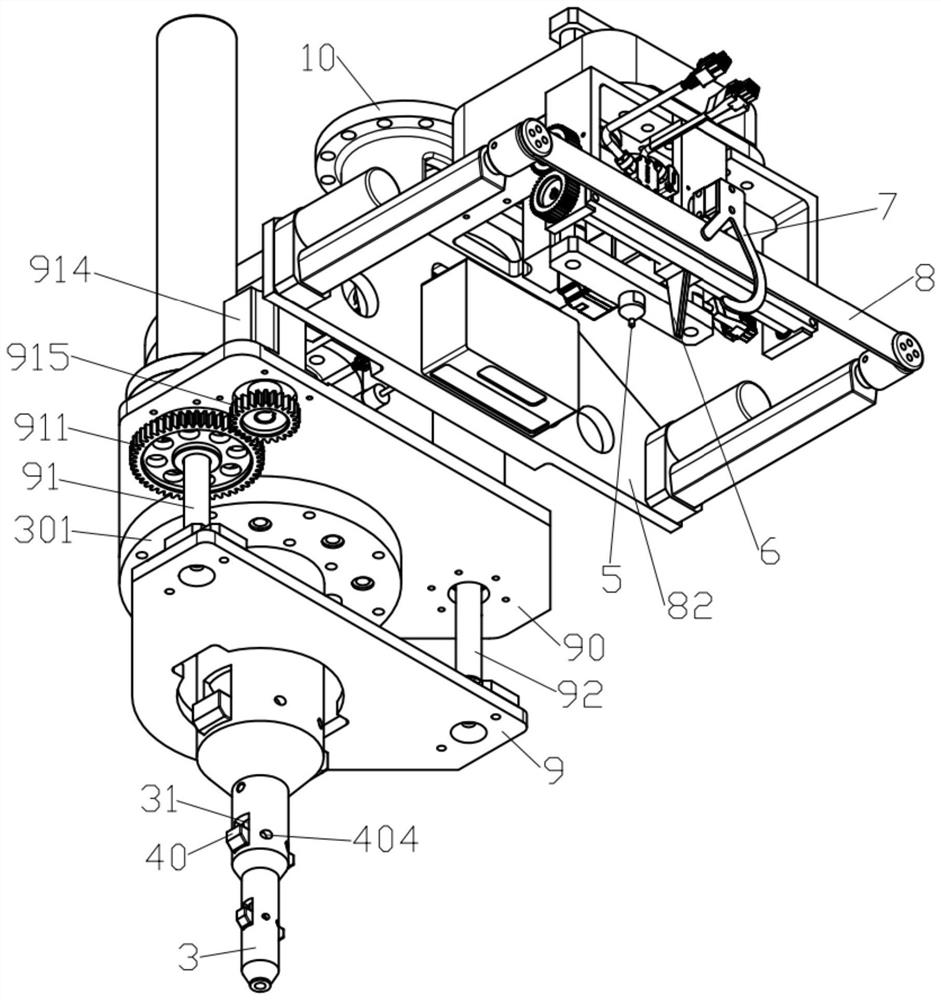

[0051] Such as Figures 5 to 7 As shown, the hoisting device includes a suspension pan shaft 3 , a control shaft 4 and a hinge block assembly 40 . The suspension pan shaft 3 is a hollow structure, the control shaft 4 is located in the suspension pan shaft 3, the hinge block assembly 40 is arranged symmetrically with respect to the control shaft 4, and the hinge block assembly 40 is rotatably connected to the suspension pan shaft 3 through the po...

Embodiment 2

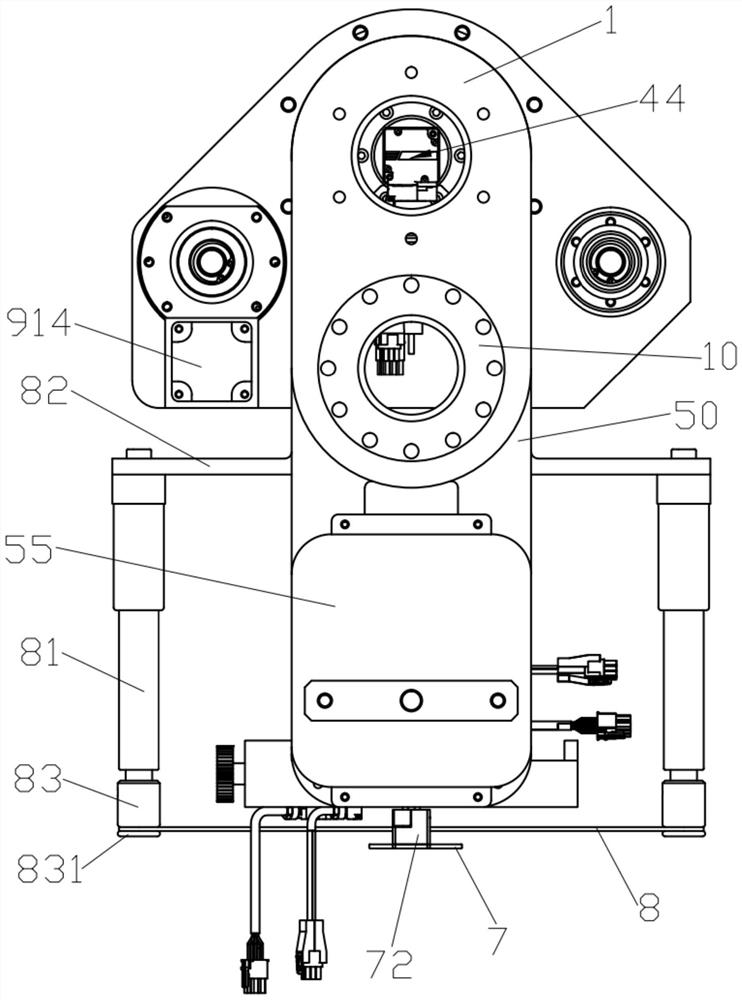

[0071] Such as Figures 21 to 22 As shown, the main difference between the full-automatic suspension mechanism described in Embodiment 2 and Embodiment 1 is that the control shaft driver 44 for driving the control shaft 4, the lifting structure of the driving plate tool pressing plate 9, and the driving off-line top 5 The off-line drivers are different. In this embodiment, pneumatic control is mainly used.

[0072] Such as Figure 22 As shown, the control shaft driver 44 is a cylinder 44B. The cylinder body of the cylinder 44B is installed on the top of the suspension pan shaft 3 . The piston rod of the cylinder 44B is connected to the top of the control shaft 4 . When the cylinder 44B is used as the control shaft driving member 44, the up and down movement of the control shaft 4 relative to the suspension pan shaft 3 is realized through the expansion and contraction of the piston rod of the cylinder 44B. Specifically, when the piston rod of the cylinder 44B stretches out, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com