A safety transportation device for new energy cell processing

A technology for transportation devices and batteries, which is applied in the directions of transportation and packaging, packaging, and packaged item types, etc. It can solve the problems of inconvenient picking up batteries one by one, and achieve the effect of enhancing the stability of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Such as figure 1 , figure 2 and image 3 As shown, a safe transportation device for new energy cell processing includes a bottom plate 1, a workbench 2, a pushing mechanism 3 and a boxing mechanism 4. 2 The rear side is provided with a push mechanism 3, and the top of the bottom plate 1 is provided with a packing mechanism 4 under the workbench 2.

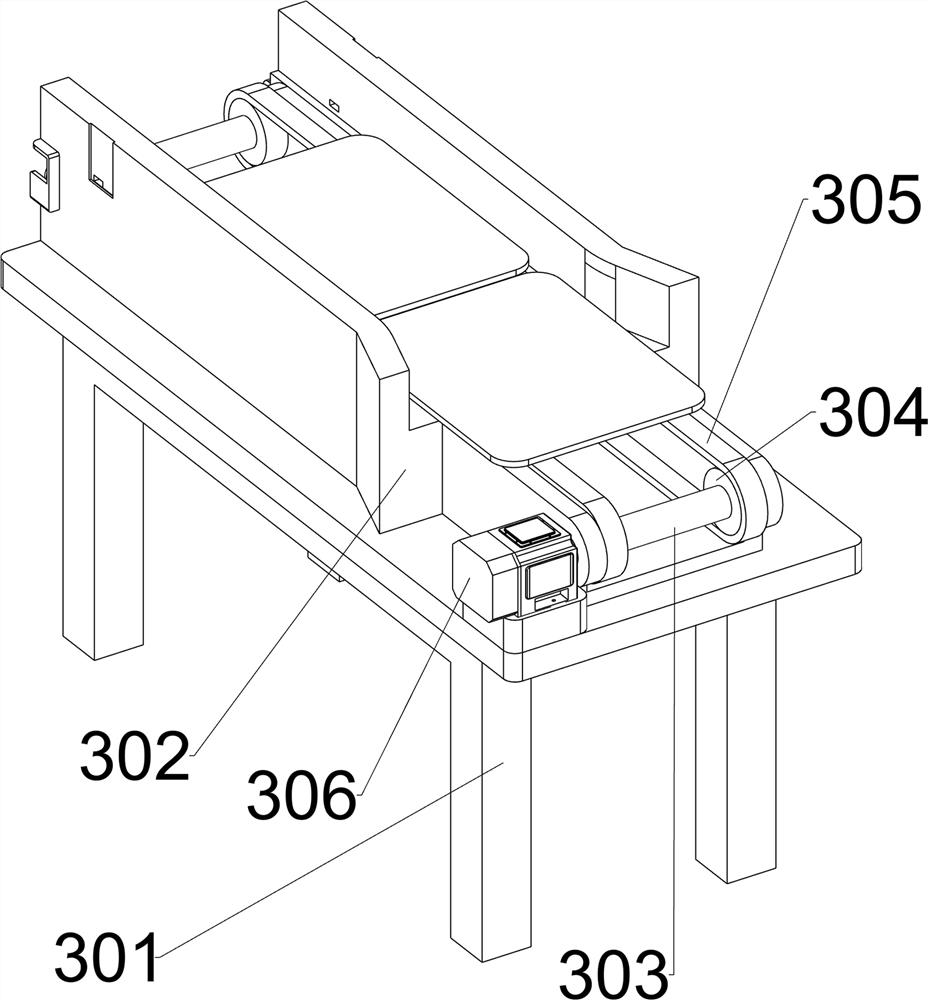

[0027] The push mechanism 3 includes a first support seat 301, a limit baffle 302, a first rotating shaft 303, a pulley 304, a conveyor belt 305, and a servo motor 306. The limit baffle 302 is arranged symmetrically on the top left and right, the first rotating shaft 303 is arranged symmetrically on the top of the first support base 301, and the belt pulley 304 is arranged symmetrically on the left and right on the first supporting seat 301, and a conveyor belt is arranged between the two pulleys 304 on the same side 305, a servo motor 306 is provided on the rear side of the top of the first support base 301, and the out...

Embodiment 2

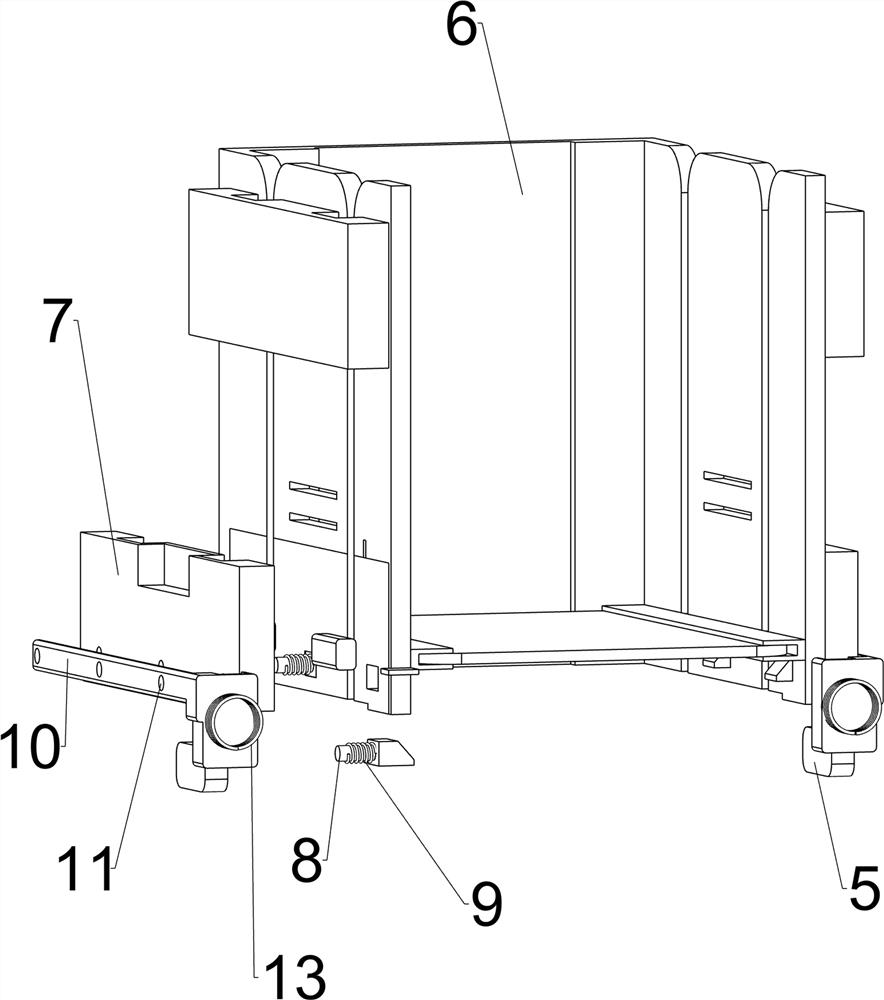

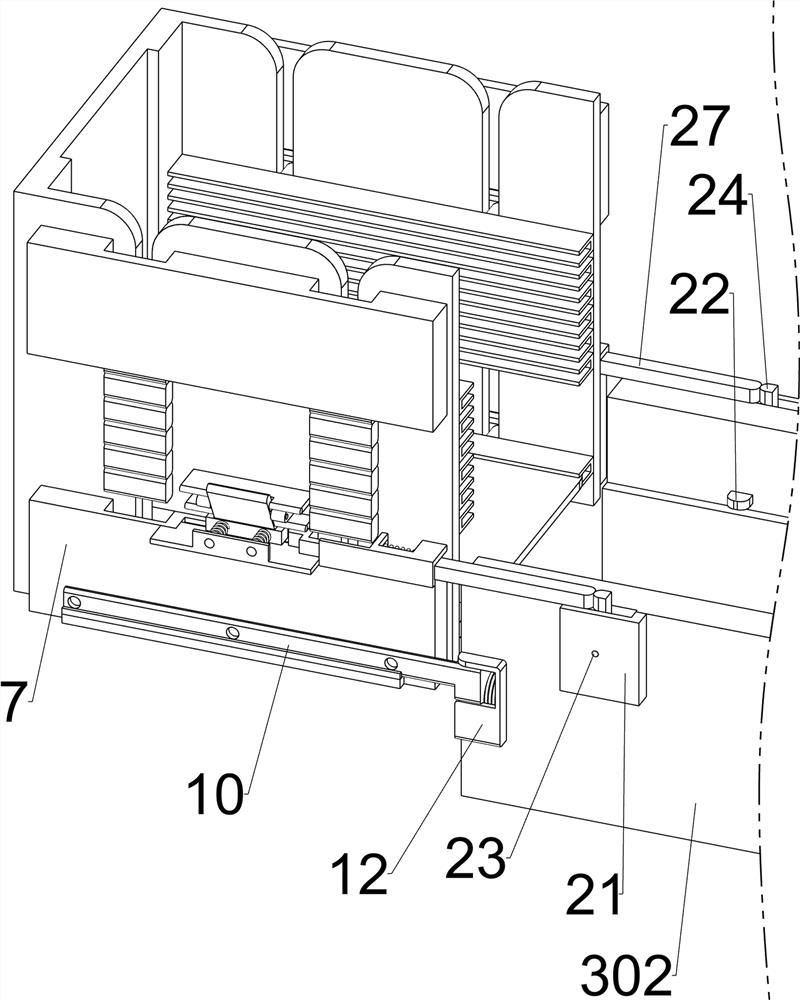

[0031] Such as Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, on the basis of Example 1, a safety transportation device for new energy cell processing also includes a top block 5, a plywood box 6, a support block 7, a limit block 8, a first elastic member 9, a limit block The gear bar 10, the block 12 and the second elastic member 13, two top blocks 5 are arranged on the cell splint 405, the splint box 6 is arranged on the top of the workbench 2, and the left and right side walls of the splint box 6 are symmetrically opened. Locating groove 404, plywood box 6 lower sides are arranged with support block 7 left and right symmetry, plywood box 6 lower sides are evenly spaced left and right symmetrical sliding type and are provided with limit block 8, and limit block 8 is slidably matched with adjacent support block 7, and limit block 8 cooperates with the cell splint 405, a first elastic member 9 is set between the limit block 8 and the adjacent support block 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com