Large pipeline continuous splicing structure and splicing method

A pipeline and large-scale technology, applied in the field of continuous splicing structure of large pipelines, can solve the problems of easy misalignment, difficult manual movement, heavy large pipelines, etc., and achieve the effect of preventing misalignment and avoiding the impact of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

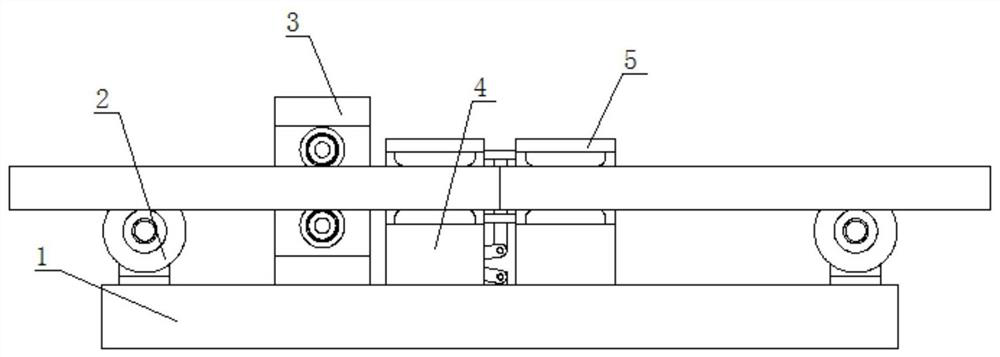

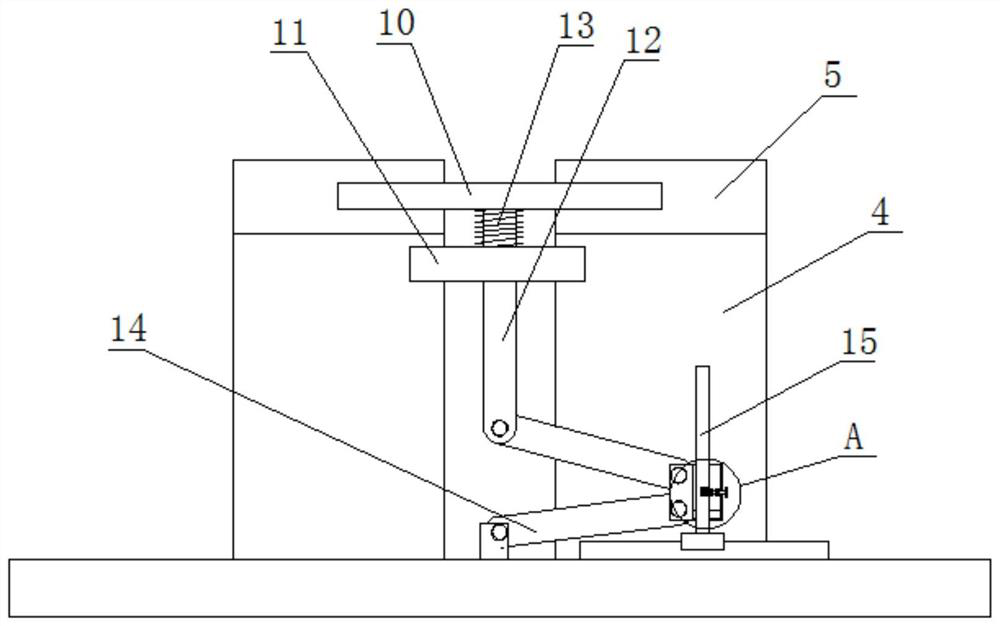

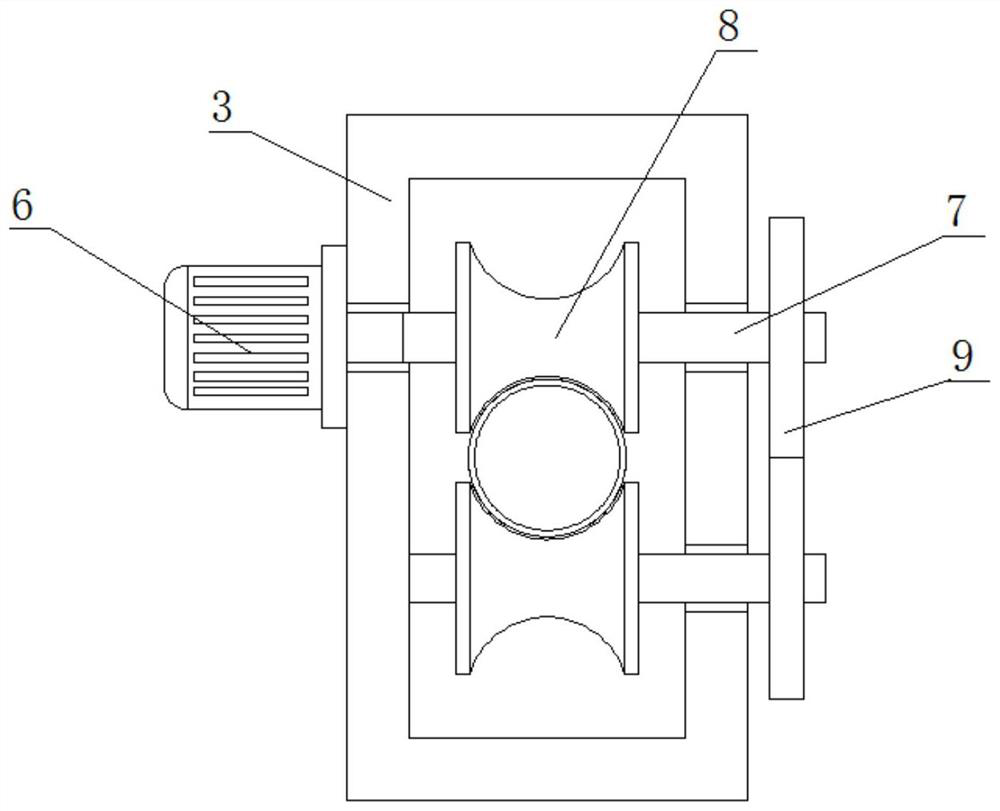

[0031] The invention provides a continuous splicing structure for large pipelines, referring to Figure 1-4 , including a base 1, the top of the base 1 is symmetrically fixed with two support bases 4, and one side of the two support bases 4 is slidably connected to the same fixed rod 10, and one side of the fixed rod 10 is symmetrically fixedly mounted with two pressure plates 5 , and the side where the pressure plate 5 and the support seat 4 are close to each other is clamped with the same pipe, the two pipes are in contact, the top of the base 1 is slidingly connected to the limit rod 15, and the limit rod 15 is slidingly sleeved with a moving ring 16 , the moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com