Scribing machine water tank welding process method and welding auxiliary device

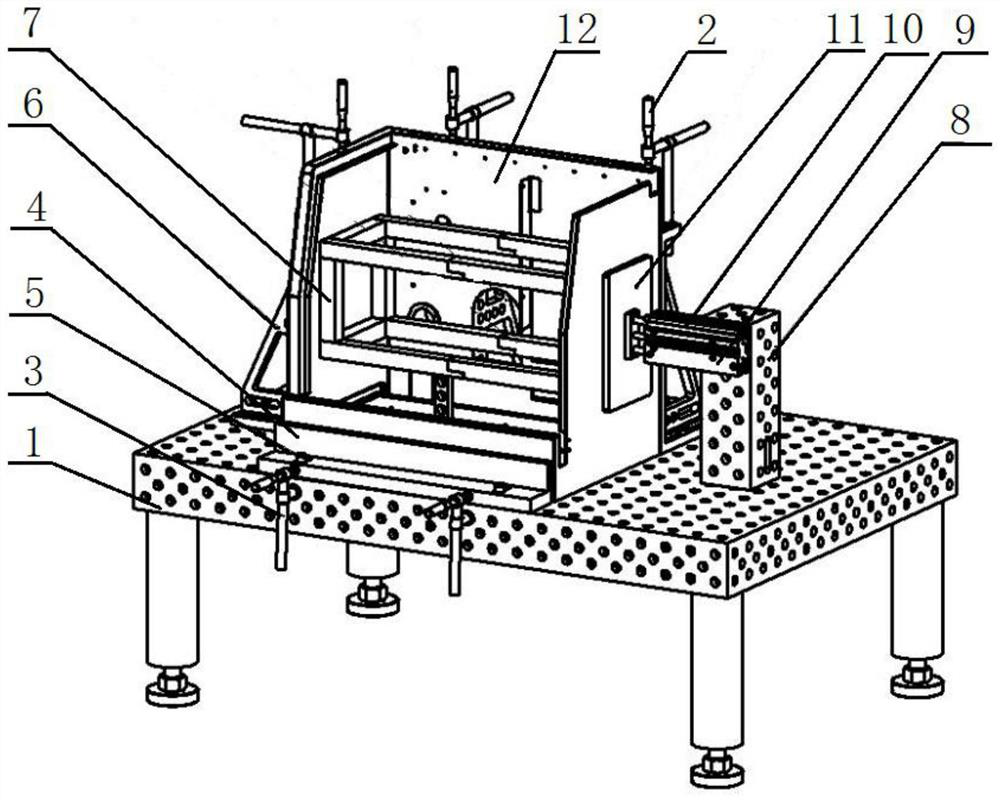

A technology of welding process and auxiliary device, which is applied in the field of dicing machine water tank welding process and welding auxiliary device, which can solve the problem of unsmooth sliding doors, large deformation after welding, protrusions on both sides of deformation, spindle or microscope cover plate and it Interference and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a welding process method for a water tank of a dicing machine, and the specific steps are:

[0024] Step 1: Mesh the water tank model, analyze the distribution of residual stress after welding, and design the 12 splicing structure of sheet metal parts;

[0025] Step 2: Design and specify the distribution and position of solder joints through genetic algorithm;

[0026] Step 3: Set the position of the clamper of the welding auxiliary device according to the welding sequence and steps;

[0027] Step 4: Set the welding auxiliary device to the initial state;

[0028] Step 5: Clamp and fix the sheet metal part 12 on the welding auxiliary device by a clamp;

[0029] Step 6: Weld according to the distribution and position of the solder joints obtained in Step 2; among them, the upper part of the bottom surface of the finished tank is full welding, and the rest is spot welding; and the overall spot welding is performed, and then the clamp is released ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com