A punching and positioning device for automobile frame

A technology of positioning device and automobile frame, which is applied to vehicle parts, transportation and packaging, etc., can solve the problems of slow speed and low drilling efficiency, and achieve the effect of fast drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

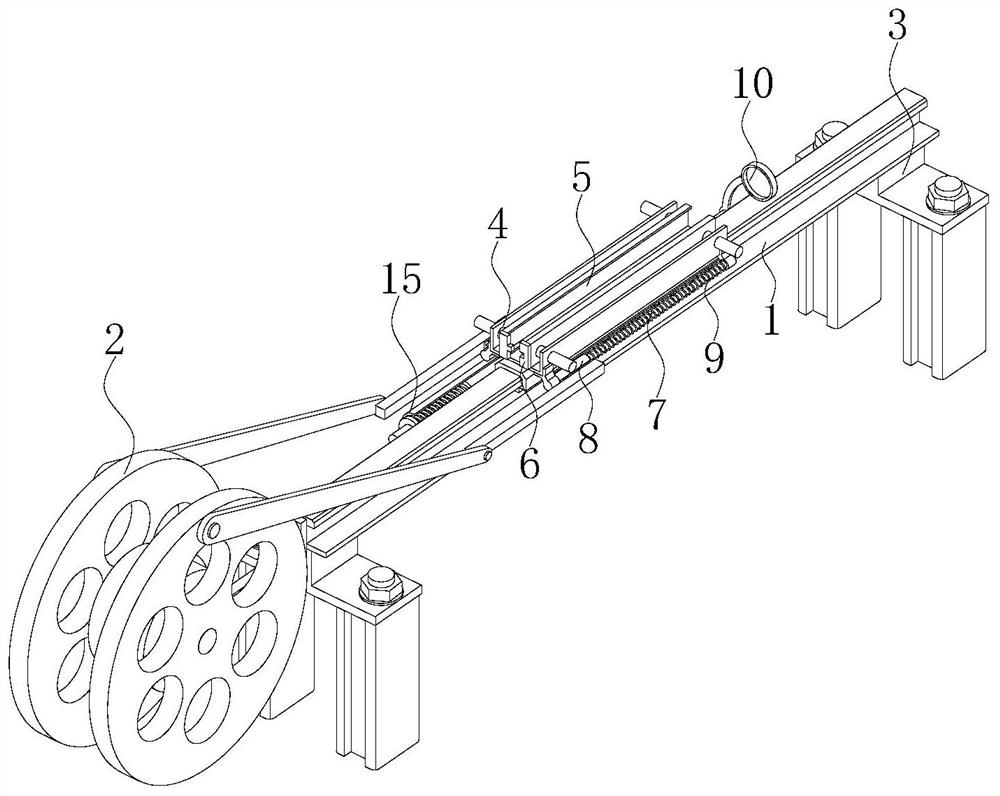

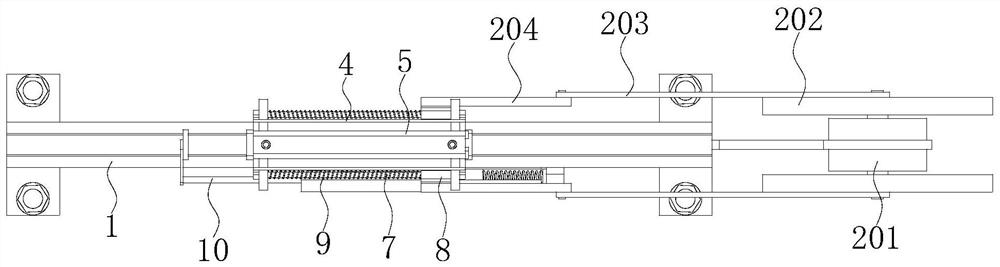

[0028] Such as Figure 1-7 As shown, a punching and positioning device for an automobile frame includes a guide rail 1, a reciprocating mechanism 2 and two brackets 3, the reciprocating mechanism 2 is installed on the left end of the guide rail 1, and the two brackets 3 are respectively located at the left and right sides of the guide rail 1. On the side, the two brackets 3 are fixedly connected with the guide rail 1, the bracket 3 can be used to support the guide rail 1, the bracket 3 can be connected with other devices, a U-shaped plate 4 is arranged above the guide rail 1, and the U-shaped plate 4 slides with the guide rail 1 connection, the bottom surface of the U-shaped plate 4 is fixed with a sliding sleeve 14, the sliding sleeve 14 is clamped on the upper end of the guide rail 1, the sliding sleeve 14 is slidingly connected with the guide rail 1, and two splints 5 are installed inside the U-shaped plate 4, U-shaped A hydraulic cylinder is installed on the plate 4, which...

Embodiment 2

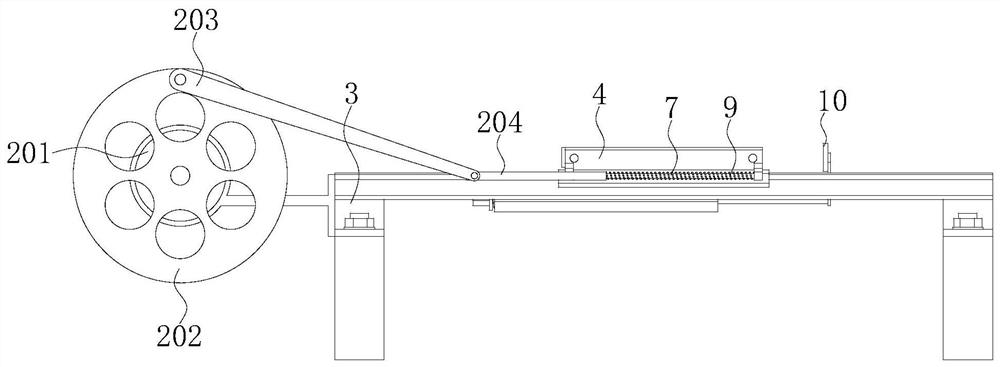

[0032] Such as Figure 1-4 As shown, the reciprocating mechanism 2 includes a biaxial motor 201, two flywheels 202 and two rockers 203, the biaxial motor 201 is fixedly connected with the left end of the guide rail 1, and the two flywheels 202 are respectively connected to the two outputs of the biaxial motor 201. The shafts are fixedly connected, and one end of the two rockers 203 is rotationally connected to the sides of the two flywheels 202 that are far away from each other. Crossbars 204 are hinged at one end of the two crossbars 202 , and the ends of the two crossbars 204 away from the two rockers 203 are respectively fixedly connected with the two sliders 8 .

[0033] When in use, the thin parts that make up the automobile body frame can be placed between the two splints 5 through the grabbing mechanism, and the effect of clamping the workpiece can be realized by making the two splints 5 close to each other, and the biaxial motor 201 is controlled to rotate , the work ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com