Orbital spraying robot

A spraying robot and track-type technology, which is applied in the direction of manipulators, spraying devices, program-controlled manipulators, etc., can solve the problems of expensive price and complex structure, and achieve the effects of convenient operation, improved processing efficiency and good spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

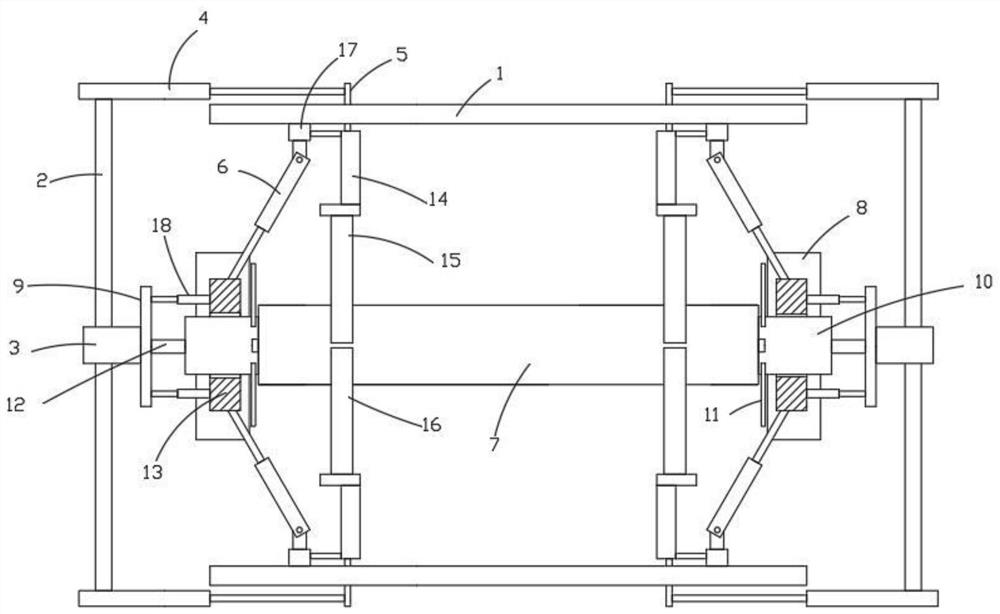

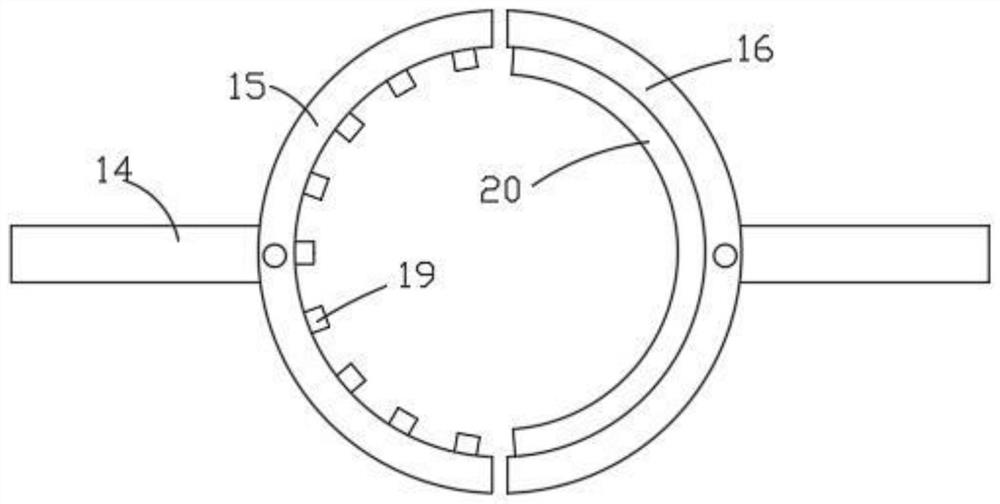

[0031] see Figure 1-4 , a track-type spraying robot, including two vertically arranged side panels 1, and each side panel 1 is provided with strip holes along the horizontal direction at both ends.

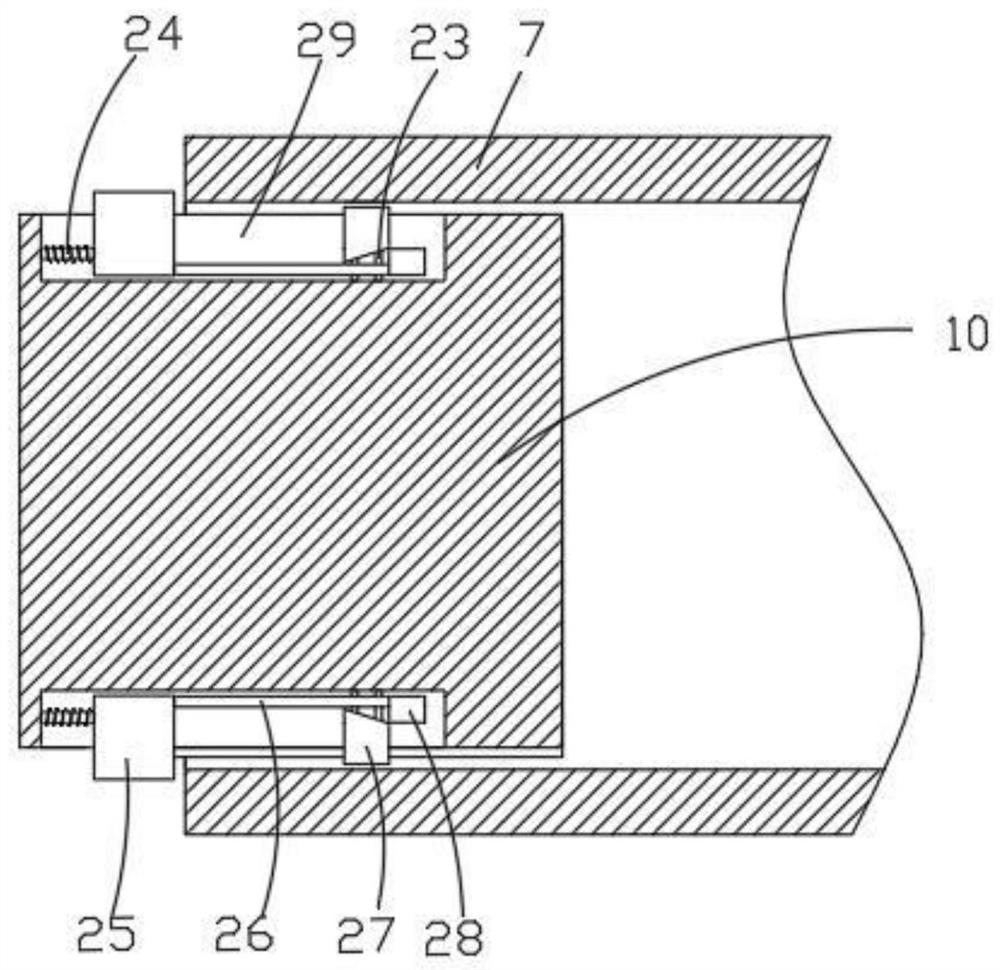

[0032] Two bases 8 are symmetrically arranged between the two fast side plates 1, and a second connecting plate 13 is vertically fixed on each base 8, and a through hole is provided on the second connecting plate 13, and a positioning plate is movable in the through hole. Block 10, the pipe 7 is clamped between the two positioning blocks 10, and one end of the positioning block 10 protrudes into the pipe 7, and presses against the inner wall of the pipe 7 through a pressing mechanism.

[0033] Rotating shafts 12 are respectively fixed on the far sides of the two positioning blocks 10, and the rotating shafts 12 are arranged coaxially, and the other ends of the two rotating shafts 12 are driven and connected with motors, and the two motors are respectively installed in the two sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com