A paint spraying device for automobile door panel processing

A technology for door panels and automobiles, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of increasing the labor force of workers and affecting the effect of painting, so as to achieve the effects of improving spraying effect, improving usability and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

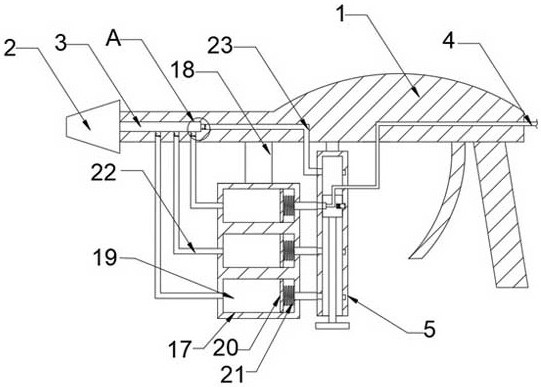

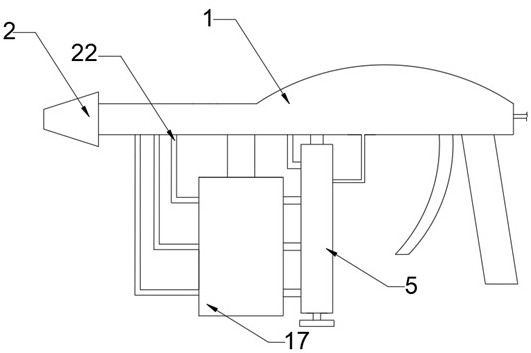

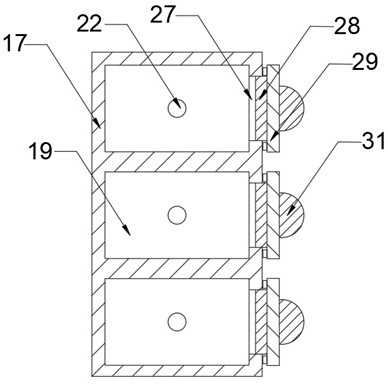

[0032]The following preferred embodiments of the present invention in conjunction with the accompanying drawings will be described, it should be understood that the preferred embodiments described herein are only used to illustrate and interpret the present invention, and are not intended to limit the present invention:

[0033] as Figure 1-9 Show: a car door plate processing spraying device, including the gun body 1, one end of the gun body 1 is connected to the nozzle 2, the gun body 1 is opened with a storage chamber 3, the storage chamber 3 is connected with the nozzle 2, one end of the gun body 1 is worn with the first intake pipe 4, the lower end of the gun body 1 is fixedly connected with the column 5, the lower end of the column 5 is opened with a circular groove 6, the surface of the column 5 is opened with multiple air outlets 7, the air outlet 7 is connected with the circular groove 6, the circular groove 6 is provided with the first piston 8, and the surface of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com