Straw crushing device

A straw pulverizing and straw technology is applied in the field of straw pulverizing devices, which can solve the problems of equipment damage and inability to guarantee the size of material particles, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

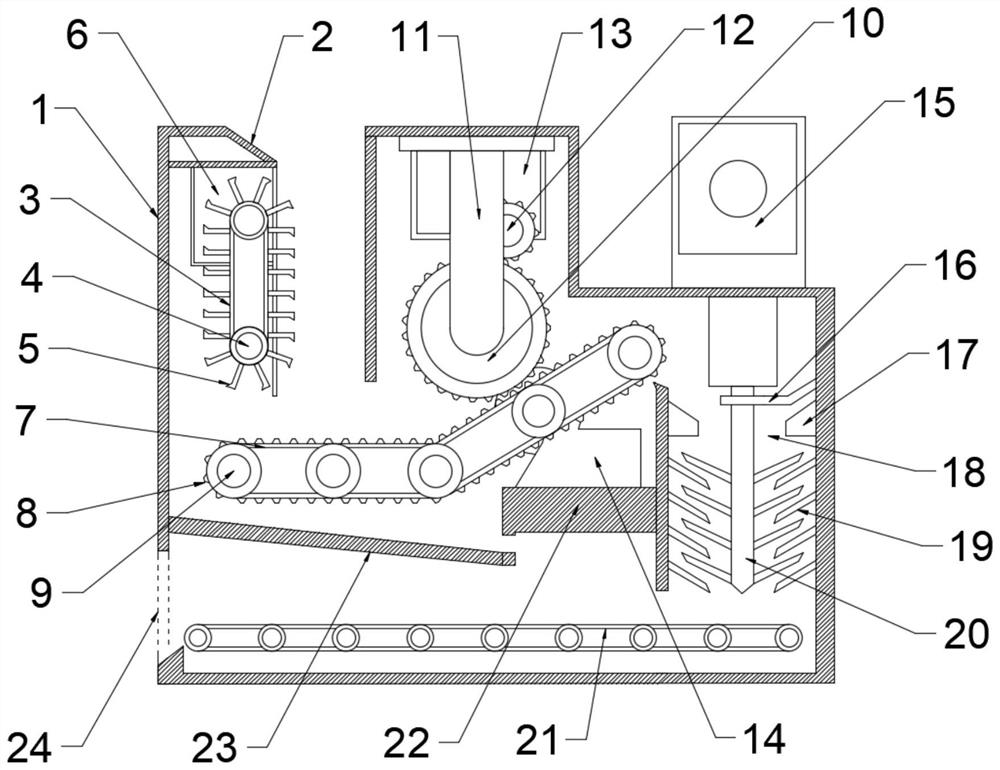

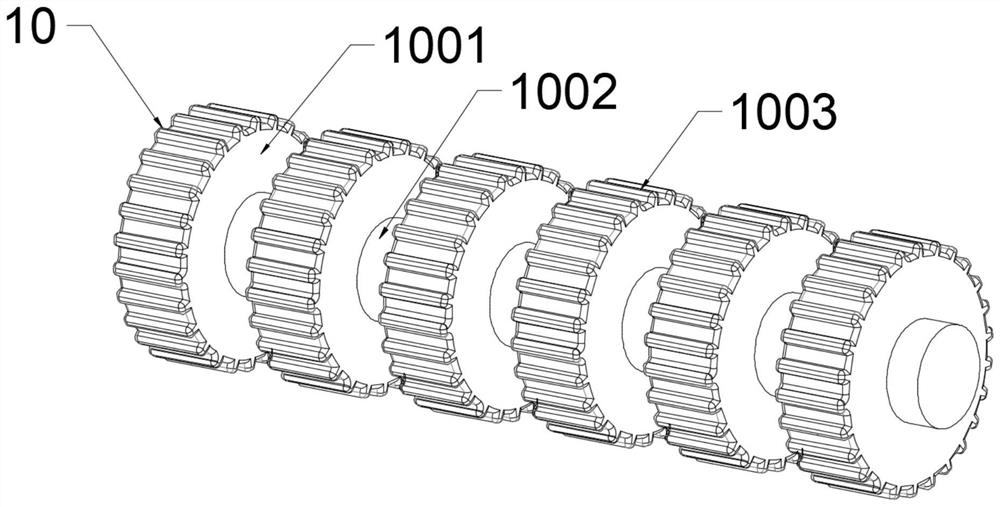

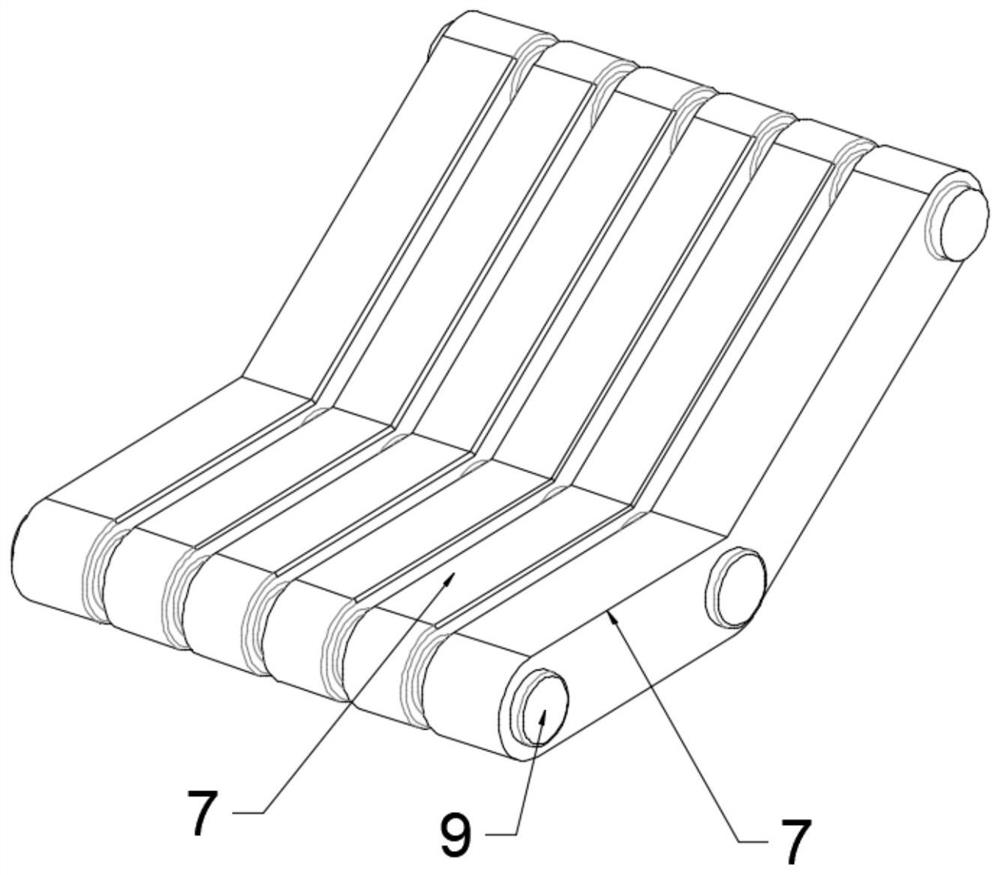

[0028] see Figure 1 ~ Figure 4 , a straw crushing device, comprising a straw crushing box 1, an auxiliary feeding belt 7, a feeding tooth 8, a feeding wheel 9, a pressing device 10, a section cutting device 14, a crushing motor 15, a rotary cutter 20 and a discharge pulley 21, wherein the feeding wheel 9 is set in the middle of the straw crushing box 1, the feeding wheel 9 is provided with an auxiliary feeding belt 7, the surface of the auxiliary feeding belt 7 is provided with a number of feeding teeth 8, and the upper part of the auxiliary feeding belt 7 is provided. The pressing device 10, the pressing device 10 includes a pressing wheel 1001, a linkage shaft 1002 and a pressing tooth 1003, wherein the middle part of the pressing wheel 1001 is provided with a linkage shaft 1002, and the pressing wheels 1001 are equidistantly installed on the linkage shaft 1002. A number of pressing teeth 1003 are provided on the surface of the material wheel 1001, and a segmented cutting d...

Embodiment 2

[0033] see Figure 5 , a straw crushing device, the main structure of which is the same as that of Embodiment 1, the material crushing chamber 18 is improved, and the rotary cutting knife 20 is replaced by an arc-shaped cutting shaft 25, and the bottom of the arc-shaped cutting shaft 25 is provided with a bearing 28, The side of the bearing 28 is provided with a hollow fixed frame 29, and the hollow fixed frame 29 is fixedly connected with the straw crushing box 1. The side of the arc-shaped cutting shaft 25 is provided with an arc-shaped cutting block 26, and the surfaces of the arc-shaped cutting shaft 25 and the arc-shaped cutting block 26 are Cutting blades 27 are arranged on the top, and an infrared rangefinder 30 is arranged below the pulverizing motor 15 .

[0034] The working principle of the present invention is: when the cut stalks follow the auxiliary feeding belt 7 and fall into the material crushing chamber 18 on the right, the crushing motor 15 above the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com