Iron-nitrogen doped hollow porous carbon material and preparation method thereof

A porous carbon material, hollow technology, used in electrical components, battery electrodes, circuits, etc., can solve the problems of restricting the application of MOFs, poor conductivity, etc., to increase the density of active sites, uniform size, enhance conductivity and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

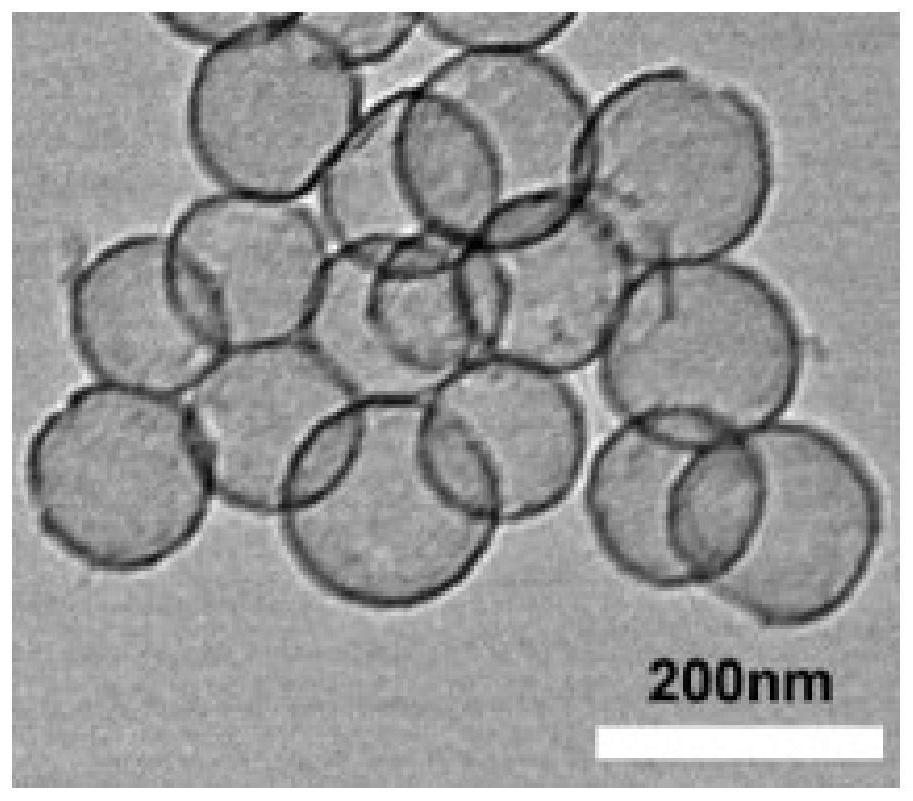

[0029] An embodiment of the iron-nitrogen-doped hollow porous carbon material of the present invention, the preparation method of the iron-nitrogen-doped hollow porous carbon material described in this embodiment includes the following steps:

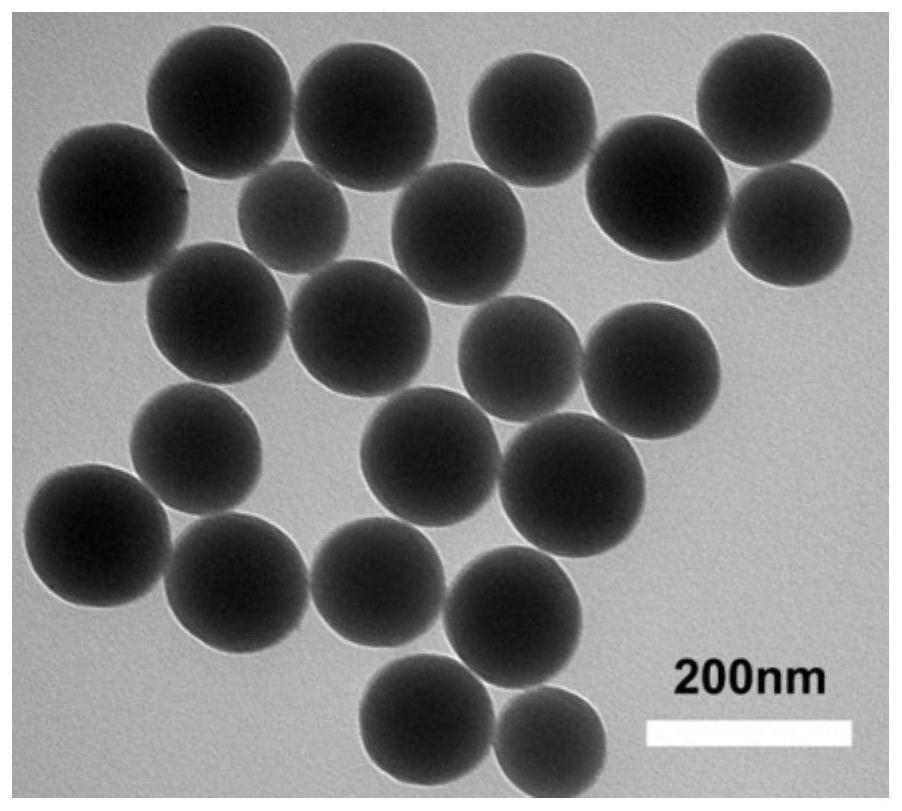

[0030] (1) SiO 2 Synthesis of spheres: Mix 0.6mL tetraethyl orthosilicate, 15mL ethanol, 0.7mL ammonia water with a mass fraction of 25-28% and 5mL deionized water, stir for 10h, centrifuge at 8000rpm for 3min, wash with ethanol 3 times, After drying in a vacuum oven for 12h, the SiO 2 ball;

[0031] (2) PP-SiO 2 Preparation: 3g SiO 2 Add 80mL PDDA mass fraction of 1% PDDA solution into the ball, stir for 1h, centrifuge and wash to obtain P-SiO 2 ; Then the prepared P-SiO 2 Add 80mL of PSS solution with a mass fraction of 1% PSS, stir for 1h, centrifuge and wash to obtain the PP-SiO 2 ;

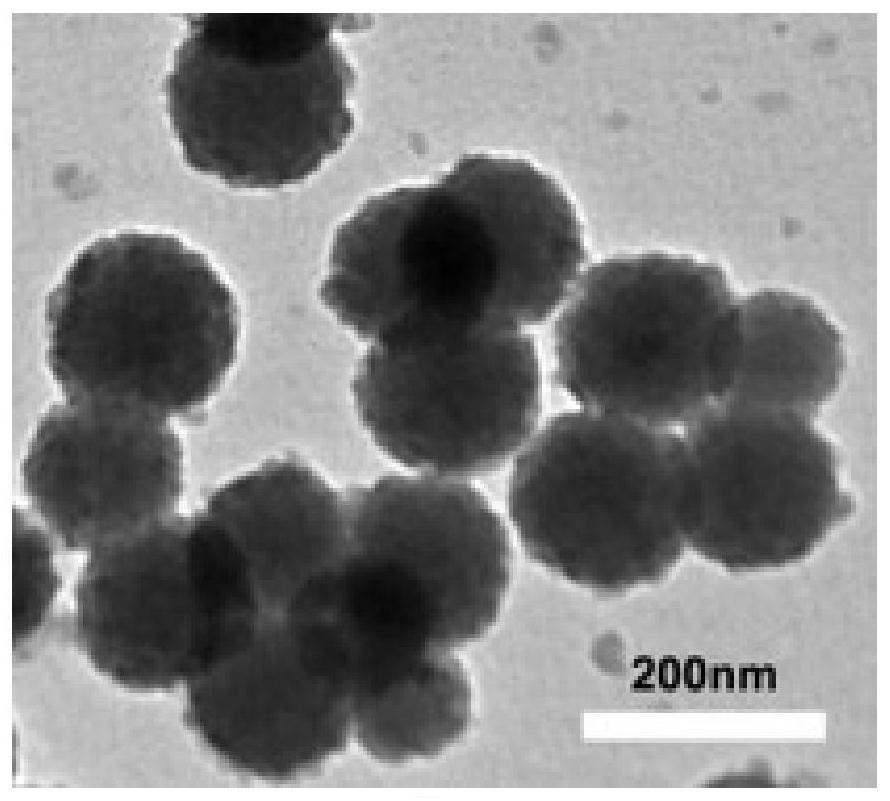

[0032] (3) PP-SiO 2 Preparation of @ZIF-8-Fe: Dissolve 200mg 2-methylimidazole in 10mL methanol to obtain 2-methylimidazole solution; then 150...

Embodiment 2

[0035] An embodiment of the iron-nitrogen-doped hollow porous carbon material of the present invention, the preparation method of the iron-nitrogen-doped hollow porous carbon material described in this embodiment is except that the content of iron nitrate nonahydrate is 10 mg, the remaining preparation steps All the same as in Example 1.

Embodiment 3

[0037] An embodiment of the iron-nitrogen-doped hollow porous carbon material of the present invention, in the preparation method of the iron-nitrogen-doped hollow porous carbon material described in this embodiment, the content of iron nitrate nonahydrate is 20mg, and the content of PDDA solution Consumption is 90mL, in PDDA solution, the massfraction of PDDA is 0.8%, the consumption of PSS solution is 90mL, in PSS solution, the massfraction of PSS is 0.8%, all the other preparation steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com