Transformer structure and manufacturing method thereof

A manufacturing method and technology of transformers, which are applied in the manufacture of inductors/transformers/magnets, transformer/inductor shells, transformers/inductor magnetic cores, etc., can solve the problems of impeding the flow of potting glue and unfavorable mold cavity air bubble discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Some typical embodiments embodying the features and advantages of the present application will be described in detail in the description in the following paragraphs. It should be understood that this case can have various changes in different aspects without departing from the scope of this case, and the descriptions and drawings therein are used for illustration in nature rather than for limiting this case.

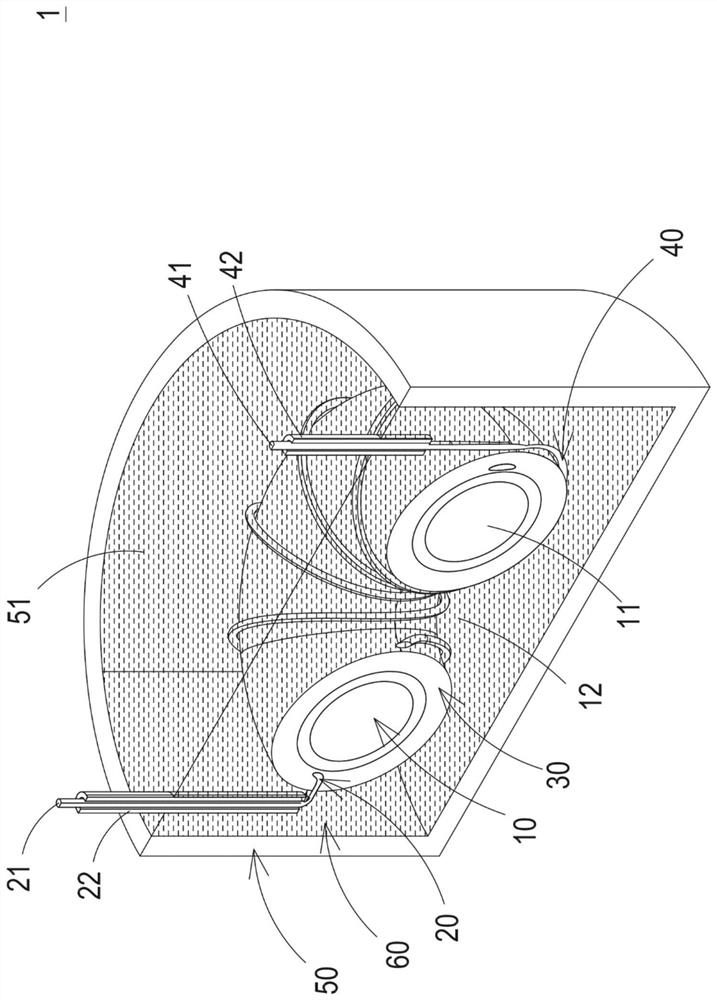

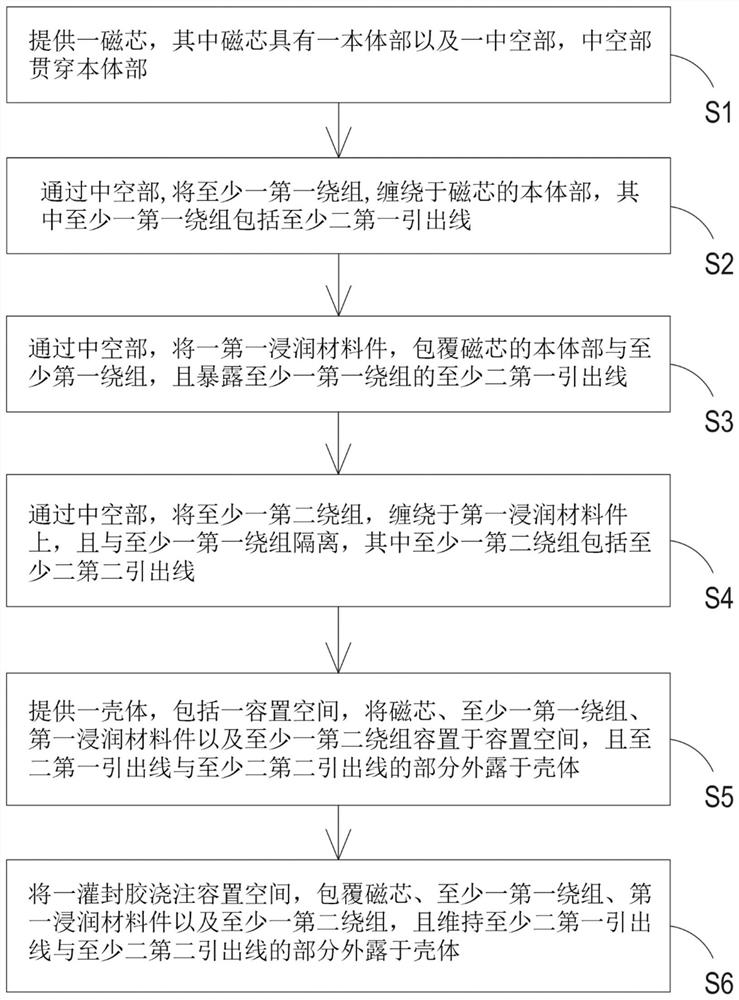

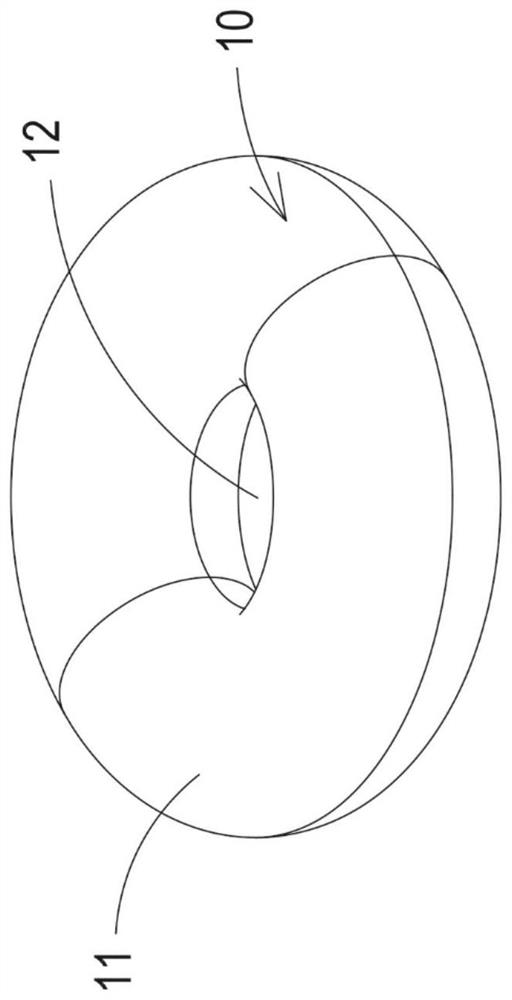

[0069] figure 1 It is a cross-sectional structure diagram of the transformer structure of the first preferred embodiment of the present application. figure 2 To disclose the manufacturing method of the transformer structure of the first preferred embodiment of the present case. Figure 3A to Figure 3E It is a schematic diagram of the transformer structure in various stages of manufacture in the first preferred embodiment of the present case. In this embodiment, the transformer structure 1 includes a magnetic core 10 , at least one first winding 20 , a first wet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com