Finite element modeling method for forged steel piston

A modeling method and finite element technology, applied in 3D modeling, image data processing, special data processing applications, etc., can solve the problem of not truly reflecting the stress of the connection between the piston ring body and the body, and not being able to truly present the piston Problems such as ring body connection relationship and inaccurate finite element analysis results have been achieved to improve design and development efficiency, accurate technical support, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described The embodiments are only some of the embodiments of the present invention, not all of them.

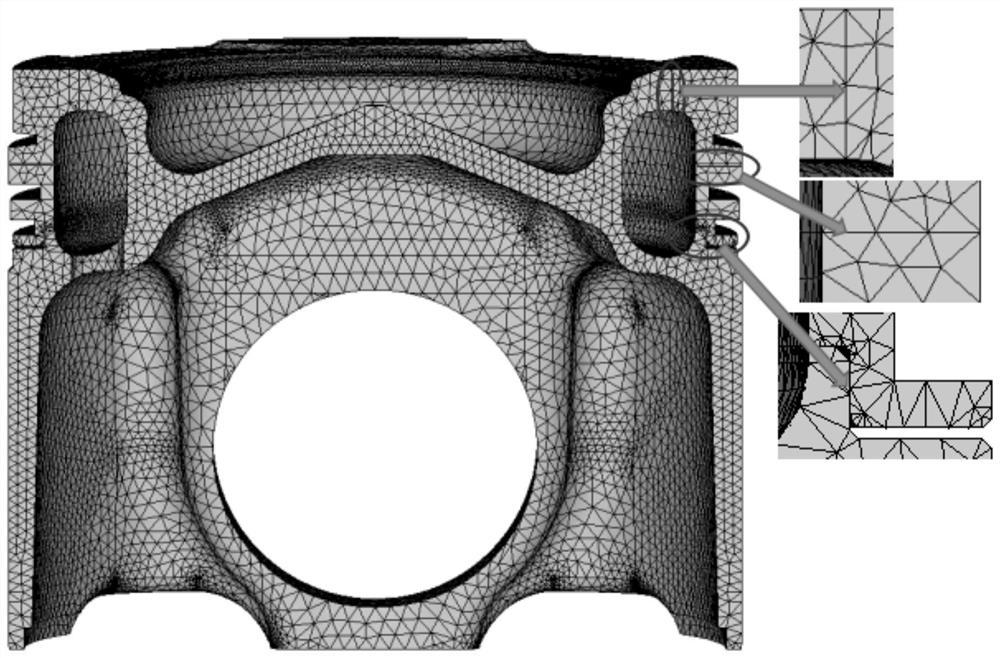

[0029] Such as Figure 1-3 As shown, a finite element modeling method of a forged steel piston specifically includes the following steps:

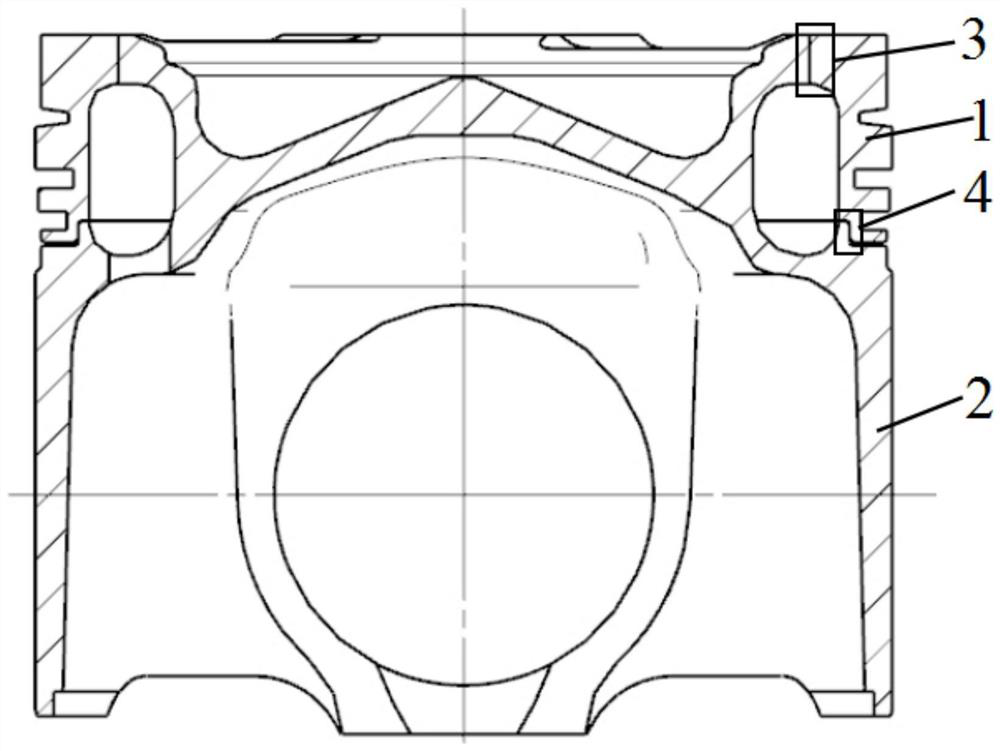

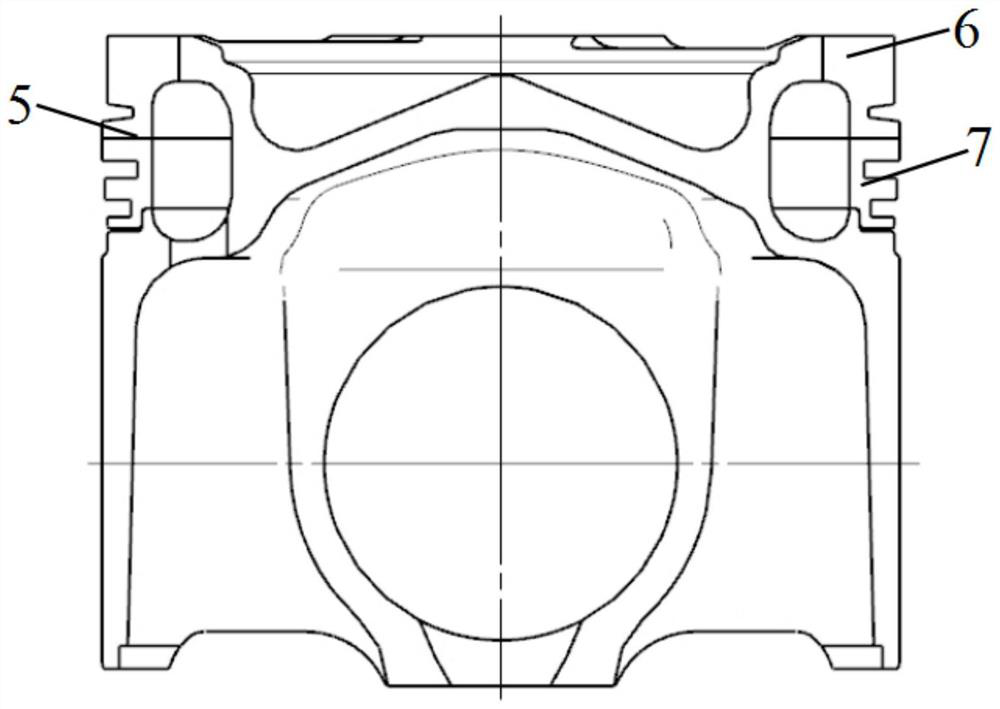

[0030] 1) Establish a three-dimensional model of the piston, and make the piston ring body 1 and the piston body 2 together, such as figure 1 As shown, the upper part is the welding area 3, and the lower part is the matching area 4; commonly used software includes: UG, Pro / E, CATIA, etc., using mature software, less investment, and high work efficiency.

[0031] The welding area 3 is where the outer cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com