An Optimal Design Method for Brake Support Structure

A technology of support structure and optimization design, applied in design optimization/simulation, mechanical equipment, combustion engine, etc., can solve problems such as damage and brake failure, and achieve the effect of optimizing manufacturing process and optimizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

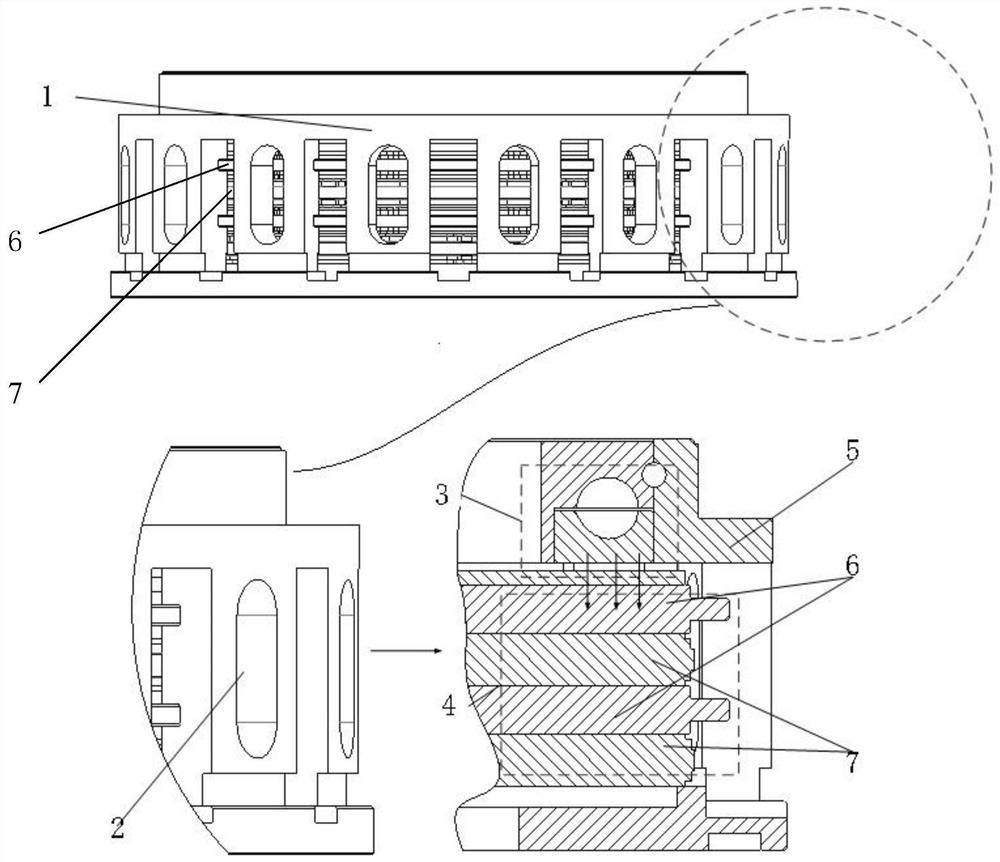

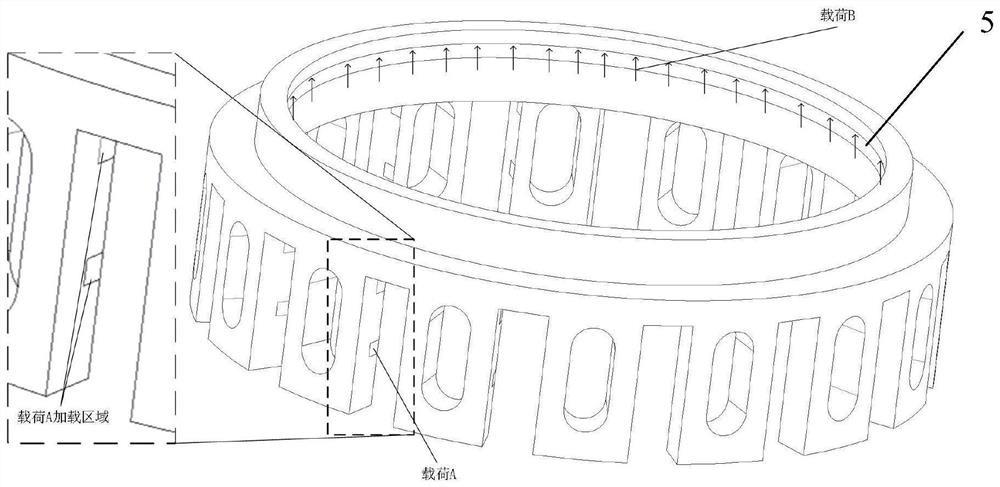

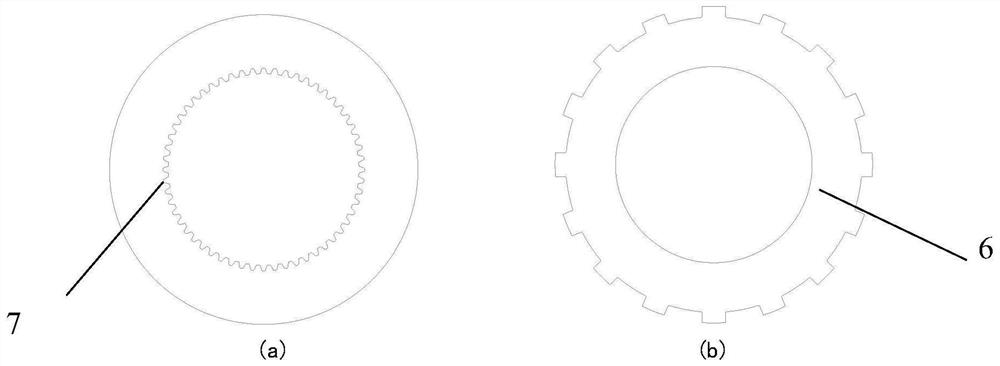

[0145] The embodiment is aimed at a certain type of dry disc brake, and the optimal design method of the present invention is used to optimize the design of its supporting structure. The brake structure is as follows: figure 1 shown. The dry disc brake has a simple and reliable structure and is easy to operate. Due to its complete contact continuous friction, the instantaneous temperature rise of the brake is low and evenly distributed, and the braking effect is stable and reliable. It is also used in various heavy vehicles. A certain type of brake support structure consists of 16 support struts fixed to the bottom surface, and the circumferential rotation effect generated by the manipulation action is converted into an axial compression effect through the marble pressing mechanism. Before the optimal design of the brake support structure, the support structure is first simplified and a 3D model is established to remove unnecessary structures such as bolt holes, card slots and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com