Visual detection system for fuse box

A fuse box and visual inspection technology, applied in the field of fuse box visual inspection systems, can solve problems such as unfavorable popularization and use, lack of details, etc., and achieve the effect of avoiding out-of-warehouse and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

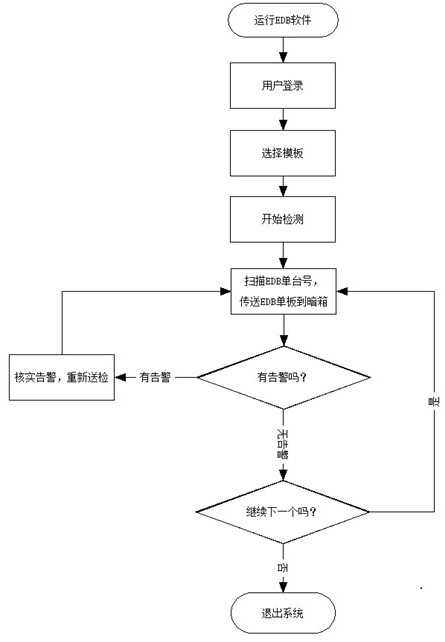

[0029] The present invention will be specifically described below in conjunction with the accompanying drawings.

[0030] as attached figure 1 , 2Shown, a kind of fuse box vision detection system is characterized in that: comprise industrial camera 4, camera obscura 1, conveyer belt 6, computer; Described industrial camera is installed on the top of camera obscura; A plurality of photographing light sources are arranged inside camera obscura; Relative position of camera obscura bottom The inlet 3 and the outlet 2 for entering and exiting the fuse box are set; the limit plate 8 is respectively set between the inlet and the outlet along the movement direction of the fuse box board 7; The initial position of the fuse box veneer is positioned at the same time; the black box is fixed on the conveyor belt; during detection, the fuse box veneer to be detected is placed on the conveyor belt 6 at the entrance, and passes through the dark box as the conveyor belt moves; the dark box an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com