Water surface transportation tool

A technology of transportation tools and cabins, which is applied in the field of transportation, and can solve problems such as the increase in the amplitude of the swing of the ship, the displacement of the cargo box, and the drop of the cargo box into the water, so as to increase the friction, reduce the amplitude, and avoid side effects. slippery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

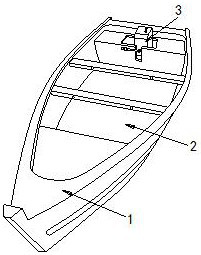

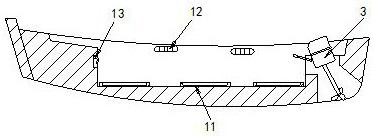

[0027] Its structure includes a hull 1, a cabin 2, and an engine 3. A cabin 2 is arranged in the middle of the hull 1. The engine 3 is installed at the rear end of the hull 1. The cabin 2 includes a fixing seat 11 and a rope tying block 12. , barb 13, described fixed seat 11 is provided with three and is installed in the inner end of cabin 2 transversely, and described rope block 12 is provided with two, and is installed in the both sides of cabin 2 respectively, and described barb 13 Embedded in the front end of the cabin 2.

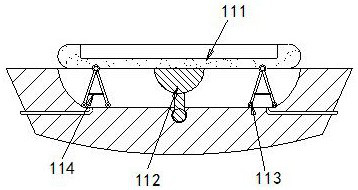

[0028] The fixed seat 11 includes a mounting seat 111, a rotating disk 112, a movable rod 113, and a tension spring 114. The bottom of the mounting seat 111 is provided with a rotating disk 112, and the rotating disk 112 is engaged in the cabin 2. The movable rod 113 There are four, and two by two are installed on the two ends of ...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0033] The mounting base 111 includes a loading groove b1, a clamping arm b2, a sliding groove b3, and a support plate b4. The two ends of the loading groove b1 are provided with a clamping arm b2, and the sliding groove b3 is provided with two, and are respectively located at both ends of the bottom of the loading trough b1. There are two support plates b4 located at both ends of the bottom of the loading trough b1. The support plates b4 are engaged in the sliding trough b3, which is conducive to placing the goods On the supporting plate b4, when the clamping arm b2 clamps the goods, the supporting plate b4 can move along with the goods.

[0034] The support plate b4 includes a board body b41, an engaging foot b42, and a rubber pad b43. The bottom of the board body b41 is provided with an engaging foot b42, and the engaging foot b42 is movably matched wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com