Four-hole button uniform perforating machine for clothes

A technology of punching machine and button, applied in the field of punching machine, can solve the problems of easy movement and poor drilling effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

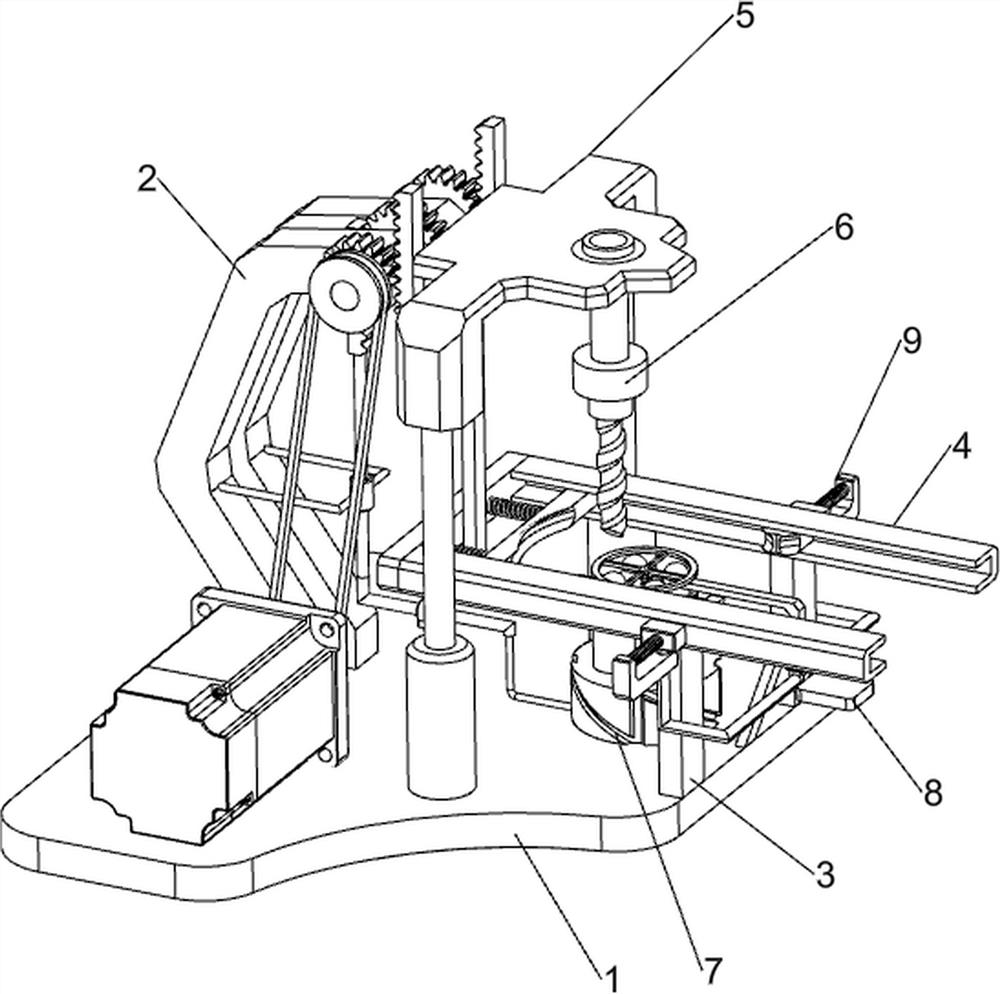

[0025] A four-hole button uniform punching machine for clothing, such as figure 1 As shown, it includes a bottom plate 1, a first support column 2, a second support column 3, a feeding frame 4, a lifting mechanism 5, an electric drill 6 and a rotating mechanism 7, and the top left side of the bottom plate 1 is fixedly connected to the front and rear symmetrically with the first support Column 2, a second support column 3 is fixedly connected front and rear symmetrically on the top right side of the bottom plate 1, a feeding rack 4 is connected between the top of the second support column 3, and a lifting mechanism 5 is arranged between the bottom plate 1 and the first support column 2, An electric drill 6 is installed at the bottom of the lifting mechanism 5 , and a rotating mechanism 7 is installed on the right side of the top of the bottom plate 1 .

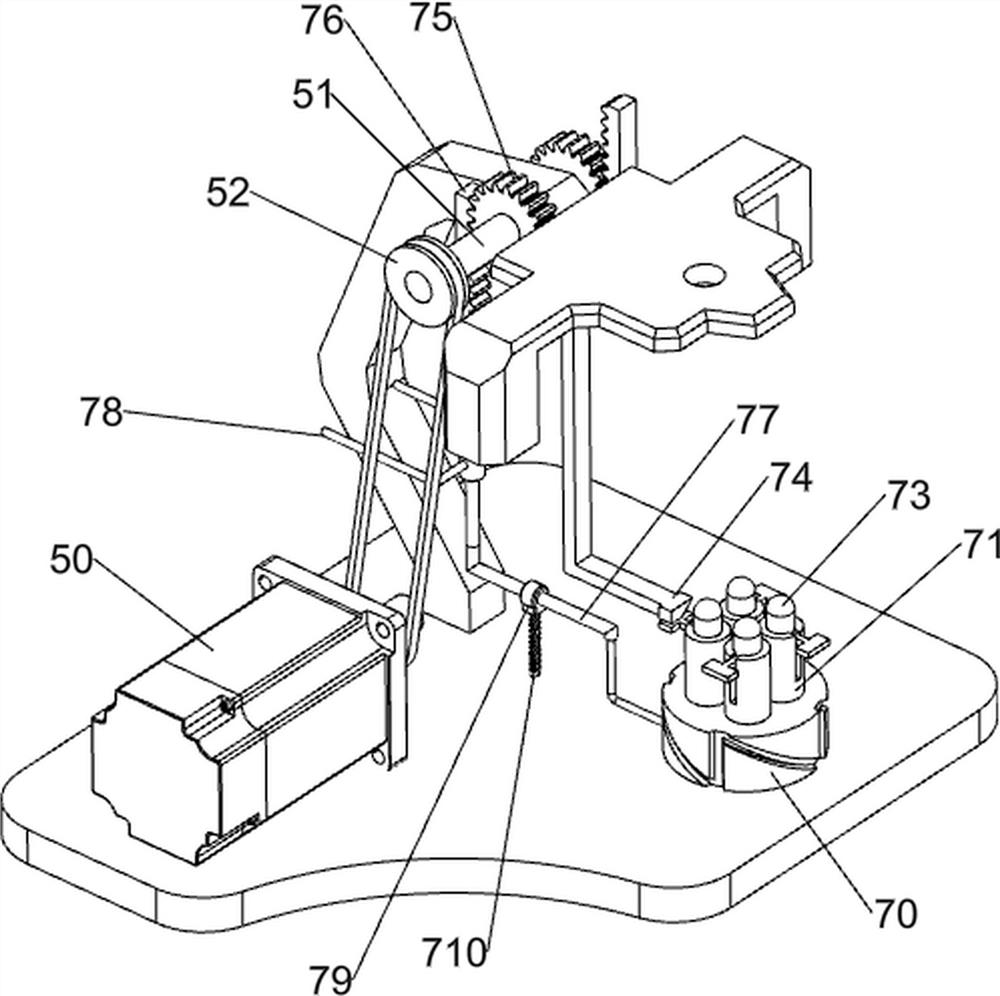

[0026] like figure 2 and image 3 As shown, the lifting mechanism 5 includes a servo motor 50, a first rotating shaft 51, ...

Embodiment 2

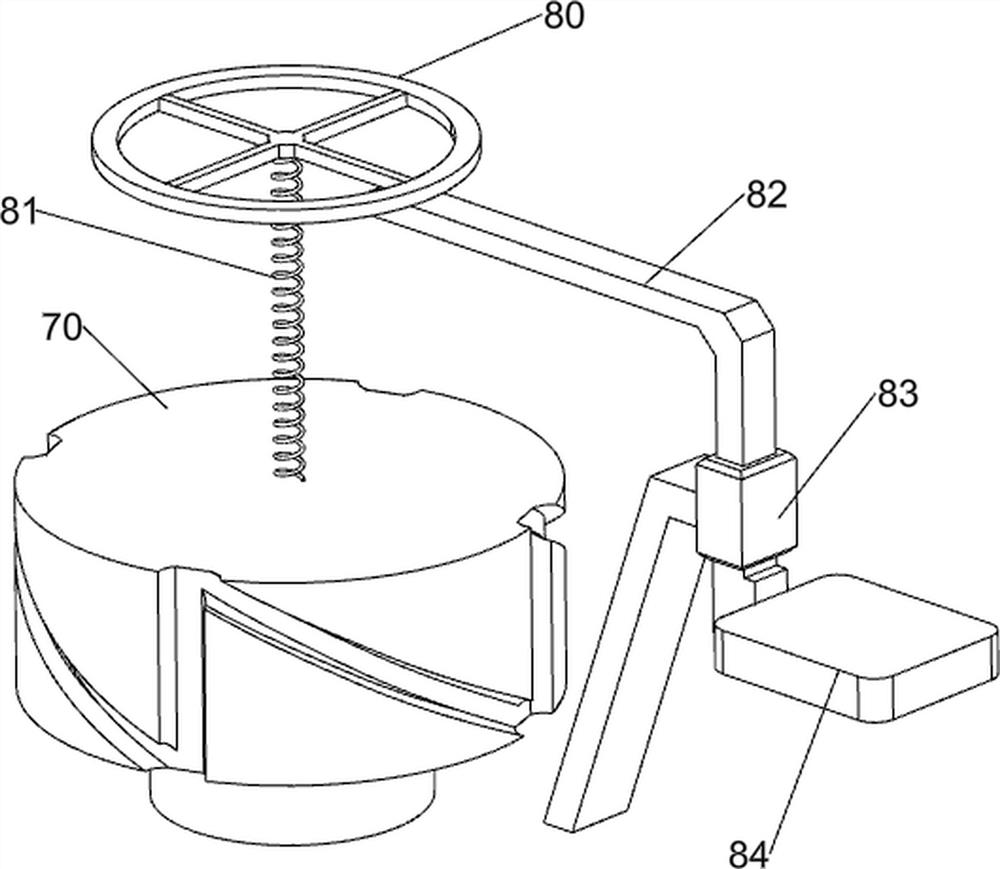

[0032] On the basis of Example 1, as Figure 7 As shown, it also includes a pressing mechanism 8. The pressing mechanism 8 includes a pressing plate 80, a fourth spring 81, a sliding plate 82, a second fixing frame 83 and a first fixing plate 84. The top of the sheave 70 is connected with a fourth The spring 81, the top of the fourth spring 81 is connected with a pressure plate 80, the middle of the top right side of the bottom plate 1 is fixedly connected with a second fixing frame 83, the second fixing frame 83 is slidably provided with a sliding plate 82, and the left end of the sliding plate 82 is fixed with the pressure plate 80 For connection, the lower end of the sliding plate 82 is connected with a first fixing plate 84 .

[0033] like Figure 8 As shown, it also includes a limiting mechanism 9, the limiting mechanism 9 includes a sliding block 90, a fifth spring 91, a second fixing plate 92, a clamping block 93, a sixth spring 94 and a fixing rod 95, and the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com