Preparation and application method of fine-mesh dust suppression net for constructional engineering

A technology of construction engineering and dust suppression net, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of poor durability of dust suppression agents and low dust suppression efficiency, and achieve reduction of dust flying, material cost reduction and Construction cost, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment provides a dense-mesh dust suppression net for construction engineering, which is composed of a dense-mesh net and a dust-suppression film, wherein the dust-suppression film is formed by a dust suppression agent sprayed on the dense-mesh net.

[0021] In 600g of sodium alginate solution with a mass fraction of 1.0%, add 300g of methyl cellulose with a mass fraction of 0.10%, and after stirring evenly, add 100g of anhydrous calcium chloride with a mass fraction of 7.0%, so that it can fully react to form a uniform texture dust suppressant, and then evenly spray the dust suppressant on the 2200 mesh / 100cm 2 on the dense network.

Embodiment 2

[0023] This embodiment provides a dense-mesh dust suppression net for construction engineering, which is composed of a dense-mesh net and a dust-suppression film, wherein the dust-suppression film is formed by a dust suppression agent sprayed on the dense-mesh net.

[0024] In 600g of sodium alginate solution with a mass fraction of 1.0%, add 300g of methyl cellulose with a mass fraction of 0.10%, and after stirring evenly, add 100g of anhydrous calcium chloride with a mass fraction of 8.0%, so that it can be fully reacted to form a uniform texture dust suppressant, and then evenly spray the dust suppressant on the 2200 mesh / 100cm 2 on the dense network.

Embodiment 3

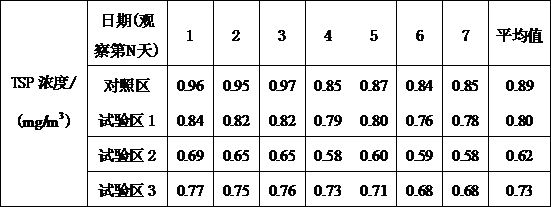

[0026] The test site is a project site with relatively open surroundings. Except for the dust generated by its own construction, it is less disturbed by road dust or other types of urban dust. This test is carried out during the main construction stage of the project. The test uses TSP concentration as the detection index of ambient air particulate matter concentration. Before the test starts, the TSP concentration in the test area and the control area is the same to ensure that the dust situation in the test area and the control area is comparable.

[0027] No treatment was done in the control area, and the test area 1 was set at 2200 mesh / 100cm 2 The dense-mesh net of the above-mentioned embodiment 1 is set in the test area 2, and the dense-mesh dust suppression net described in the above-mentioned embodiment 2 is set in the test area 3. By continuously monitoring the TSP concentration in the test area and the control area, the dense-mesh dust suppression net is evaluated. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com