Slightly spicy gelled candy and preparation process thereof

A technology for gelling candy and preparation process, which is used in the confectionery industry, confectionery, and food ingredients as a taste improver, etc., can solve the problems of no yogurt flavor, complex production process, unhealthy and other problems, and achieve good spicy taste, Simple production process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

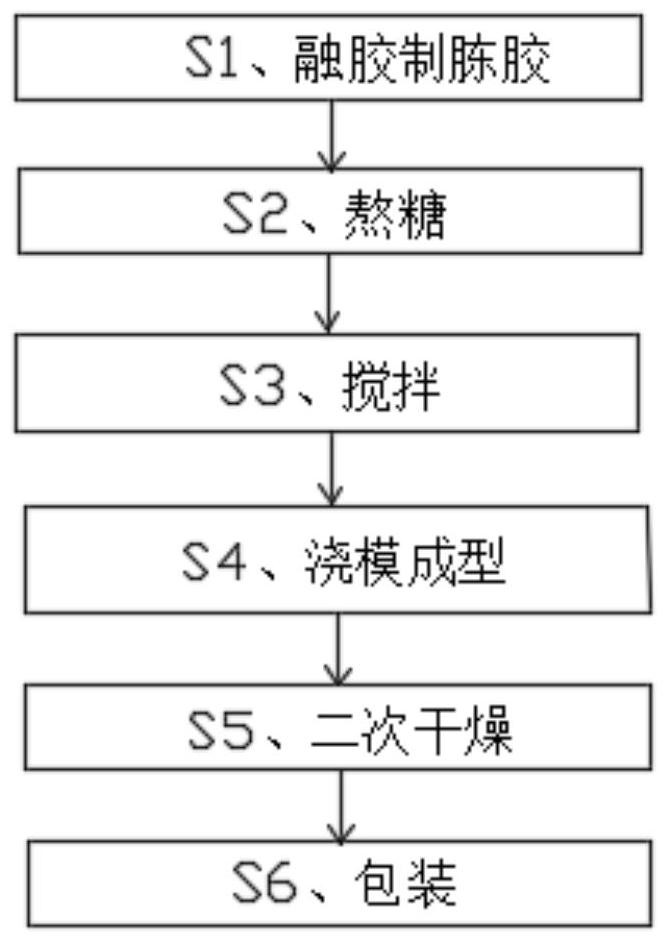

Image

Examples

Embodiment 1

[0032] refer to figure 1 , a slightly spicy jelly candy, comprising the following components in percentage by weight:

[0033] White granulated sugar 56.62%;

[0034] Glucose syrup 33%;

[0035] Edible salt 0.2%;

[0036] Spices 0.2%;

[0037] The rest are food additives.

[0038] Among them, the food additives include the following percentages of the total mass of the gel candy: acetate starch 9%, gum arabic 0.5%, lactic acid 0.2%, calcium lactate 0.1%, caprylic, capric glyceride 0.02%, shellac 0.05%, Carnauba Wax 0.1%, Allura Red 0.01%.

[0039] The analysis shows that: the slightly spicy jelly candy produced by the preparation process of this slightly spicy jelly candy has a good spicy taste, unique taste and good mouthfeel due to the addition of spices; It is much reduced, and it does not need to add a lot of glue during production, which is very healthy.

Embodiment 2

[0041] refer to figure 1 , a slightly spicy jelly candy, comprising the following components in percentage by weight:

[0042] White sugar 52.96%;

[0043] Glucose syrup 35%;

[0044] Edible salt 0.2%;

[0045] Spices 0.3%;

[0046] The rest are food additives.

[0047] Among them, the food additives include the following percentages of the total mass of the gel candy: 10% starch acetate, 0.7% gum arabic, 0.3% lactic acid, 0.2% calcium lactate, 0.03% caprylic glyceride, 0.1% shellac, Carnauba Wax 0.2%, Allura Red 0.01%.

Embodiment 3

[0049] The difference from Example 1 is that the present invention also provides a preparation process for slightly spicy jelly candy, which specifically includes the following steps:

[0050] S1. Melting peptone glue: mix and pulverize acetate starch, gum arabic, lactic acid, calcium lactate, caprylic and capric glycerides, shellac, carnauba wax, and allura red in food additives and add them to the cooking pot Carrying out boiling, first boiling it to boiling, and then boiling it at a temperature of 90° C. for 4 hours to obtain peptone gum;

[0051] S2. Boiling sugar: first dissolve the white granulated sugar, then add the glucose syrup, and boil the sugar after it is completely melted. Control the boiling temperature of the syrup to 115°C, and the sugar boiling time is 20 minutes;

[0052] S3. Stirring: when the syrup temperature of S2 is cooled to 98°C, add the peptone glue prepared by S1 melted peptone glue for stirring and blending, then add spices and stir to exhaust, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com