Method for producing fat standardized milk products and system thereof

A dairy, fat technology for the production of at least one fat-standardized dairy product with the effect of improving response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

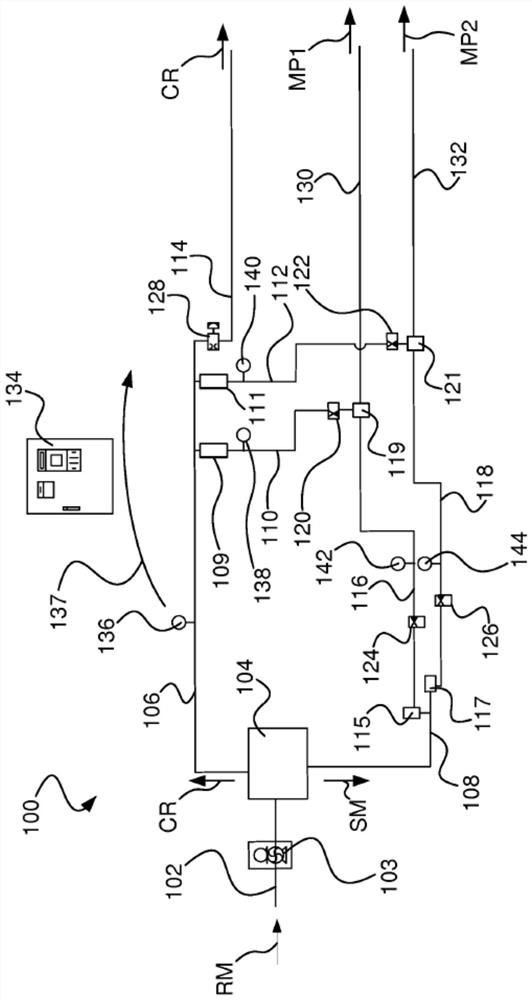

[0029] refer to figure 1 , shows by way of example a system 100 for producing a first standardized dairy product MP1 and a second standardized dairy product MP2. Even though figure 1 The example shown in involves two dairy products, it being understood that the general concept can also be used to produce one dairy product or more than two dairy products.

[0030] Raw milk RM may be fed into the system 100 via a raw milk tube 102 using a raw milk pump 103 . After entering the system 100, raw milk RM may be separated into cream CR and skim milk SM by using a separator 104. Cream CR may be fed from separator 104 in main cream line 106 (also referred to as cream line), and skim milk SM may be fed from separator 104 in main skim milk line 108 .

[0031] By using at least one divider (valve or branch) shown here by the first divider 109 and the second divider 111, the cream CR in the cream pipe 106 can be divided such that a portion of the cream is fed into the First cream remix...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap