Torsion wire loosening device for communication cable stripping machine

A communication cable and peeling machine technology, which is applied to electromechanical devices, equipment for dismantling/armoring cables, electrical components, etc., can solve the problems of difficult peeling of the protective layer, and achieve the effect of good separation effect and improved peeling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

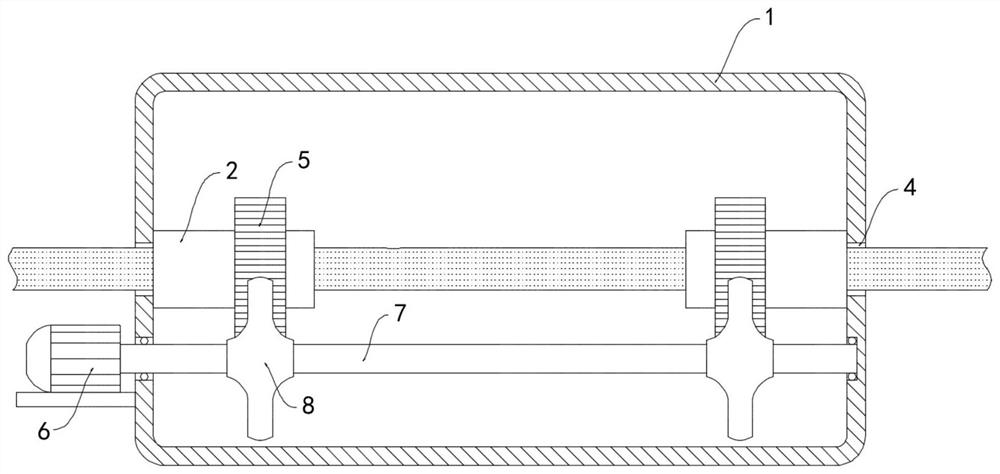

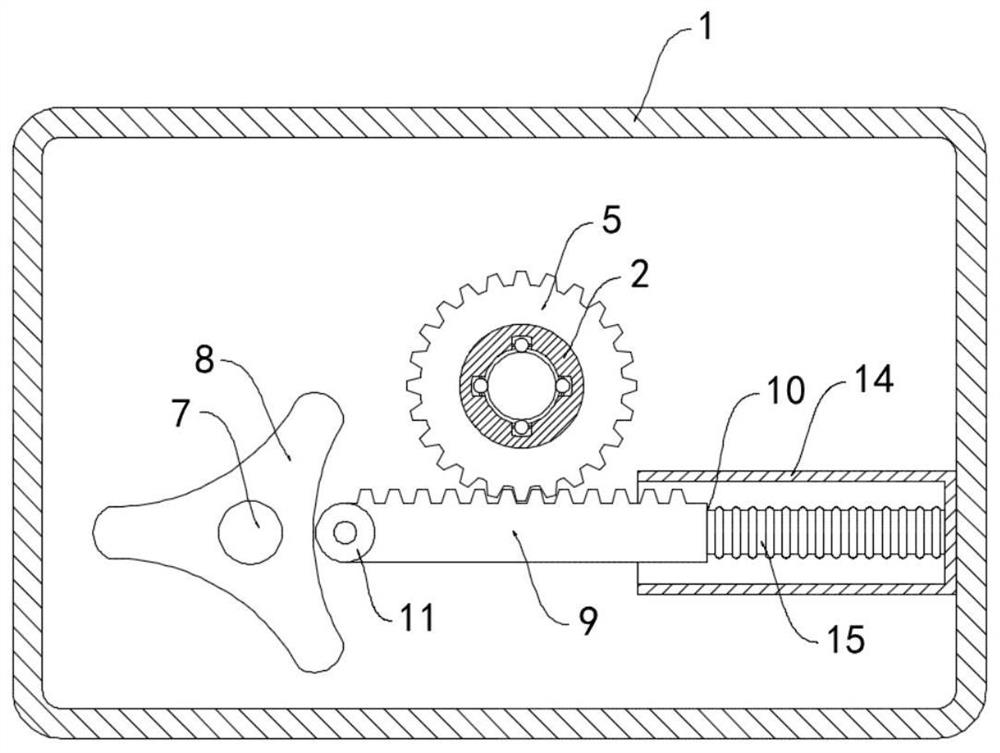

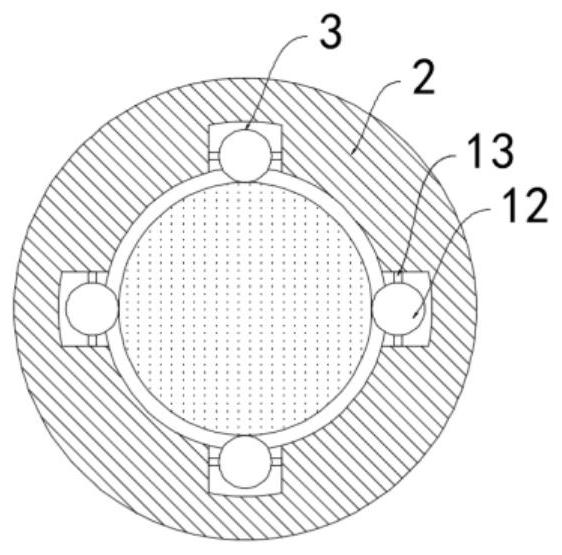

[0019] like Figure 1-3 As shown, a twisting and loosening device for a communication cable stripping machine includes a housing 1, and a rotating drum 2 is rotatably connected to the inner walls on both sides of the housing 1, and the rotating drum 2 is provided with a wire that only allows the communication cable to move along its axis. To the limit mechanism 3 that slides, the limit mechanism 3 includes grooves that are distributed on the inner side wall of the drum 2 in an annular array, and balls 12 are arranged in the grooves, and the balls 12 pass through the limit rotating rod 13 and the side wall of the groove. Rotationally connected, the limit rotating rod 13 only allows the ball 12 to rotate toward the axis of the drum 2 , and the side wall of the housing 1 is provided with a threading hole 4 corresponding to the drum 2 .

[0020] A gear 5 is coaxially and fixedly sleeved outside the drum 2, a motor 6 is installed on the side wall of the housing 1, and a rotating sh...

Embodiment 2

[0023] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that: the inner top surface and the inner bottom surface of the housing 1 are fixedly connected with the mounting seat 16, and the mounting seat 16 is provided with a plurality of equidistantly arranged chute 17 , the slide groove 17 is sealed and slidably connected with a slider 18, the slider 18 is fixedly connected with a push rod 19, the push rod 19 located on the inner top surface of the housing 1 and the push rod 19 located on the inner bottom surface of the housing 1 are alternately arranged, the sliding The slots 17 communicate with the elastic airbag 15 through the air duct 20 .

[0024] In this embodiment, when the rack 9 reciprocates in the horizontal direction, it repeatedly squeezes and stretches the elastic airbag 15. When the elastic airbag 15 is compressed, the gas in the elastic airbag 15 is squeezed into the chute 17, and the chute The air pressure in 17 increases, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com