Quantitative characterization method for early-stage propagation rate of single crystal ultrahigh-cycle fatigue internal crack

A technology of growth rate and internal crack, applied in the field of fatigue crack testing, can solve the problem of measuring crack growth rate, etc., to achieve the effect of increasing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

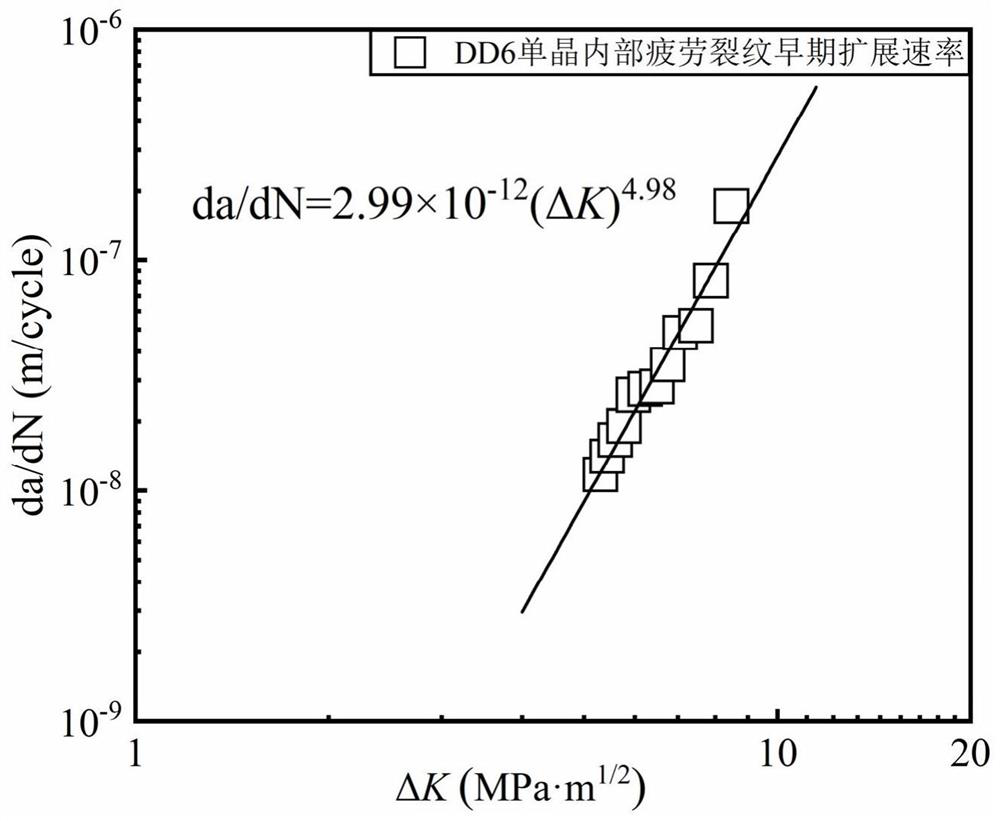

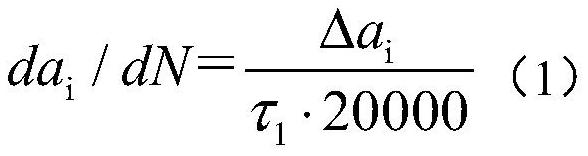

[0030] Taking DD6 single crystal as an example, the specific steps of quantitative characterization of the early growth rate of internal cracks in ultra-high cycle fatigue of single crystal based on fracture notch are as follows:

[0031] (1) Design and process the DD6 single crystal ultrasonic fatigue specimen, which is marked as specimen 1. Ultrasonic fatigue testing machine is used to conduct ultra-high cycle fatigue test on specimen 1. The test temperature is 1000°C, the test frequency is 20kHz, and the load spectrum is : 200MPa / 120ms+20MPa / 360ms, the fatigue life data and fatigue fracture of specimen 1 were obtained after the test;

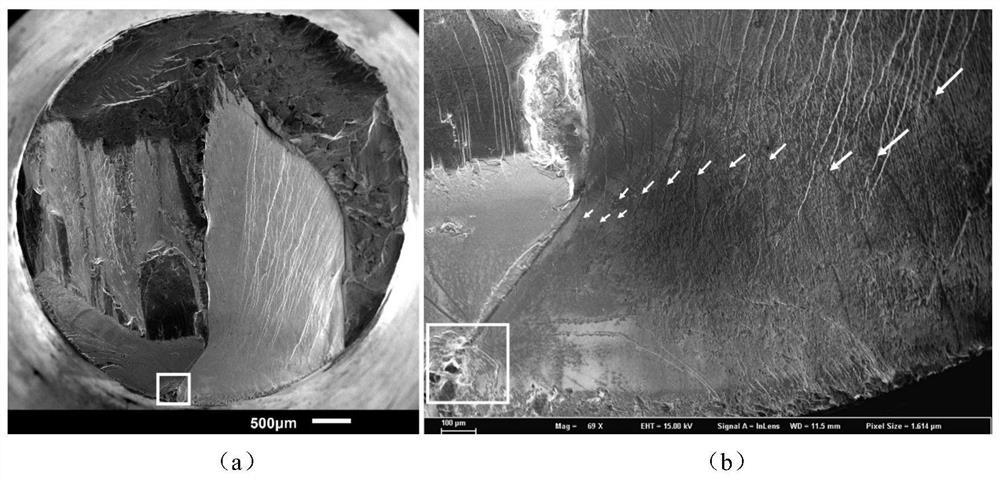

[0032] (2) Utilize scanning electron microscope to observe the fatigue fracture that obtains in step (1), figure 1 (a) is the overall morphology of the fatigue fracture (the white box shows the fatigue source area), the fatigue cracks initiate from the loose part of the internal casting, and there is a fatigue arc near the fatigue source area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com