Plastic product strength detection device

A technology for strength testing and plastic products, applied in the field of plastic parts processing, can solve the problems of lack of safety protection, inconvenient clamping, low detection efficiency, etc., and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

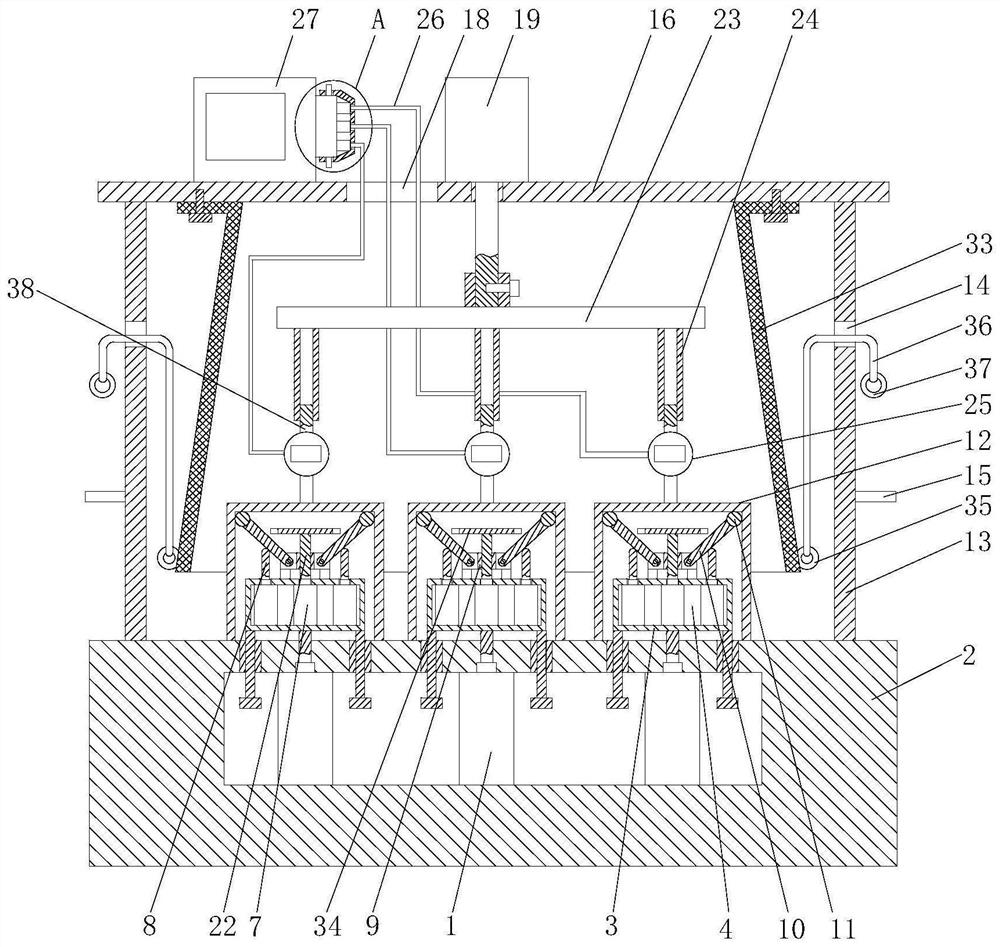

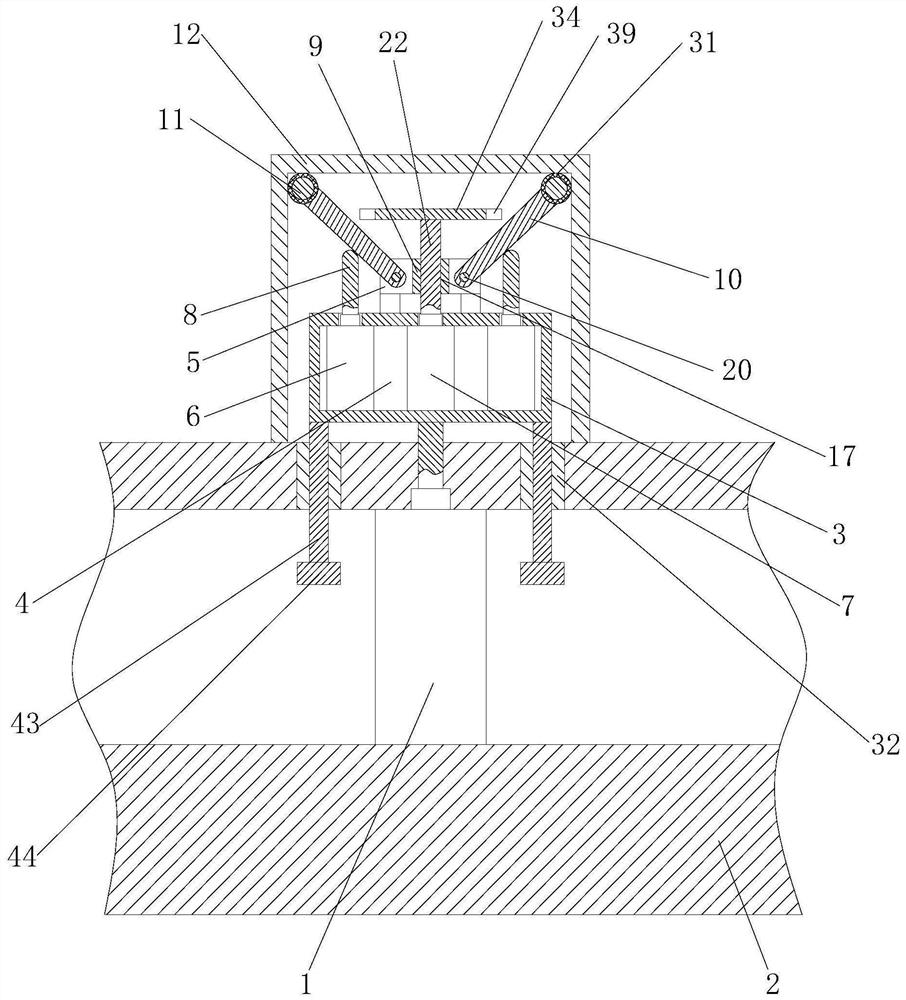

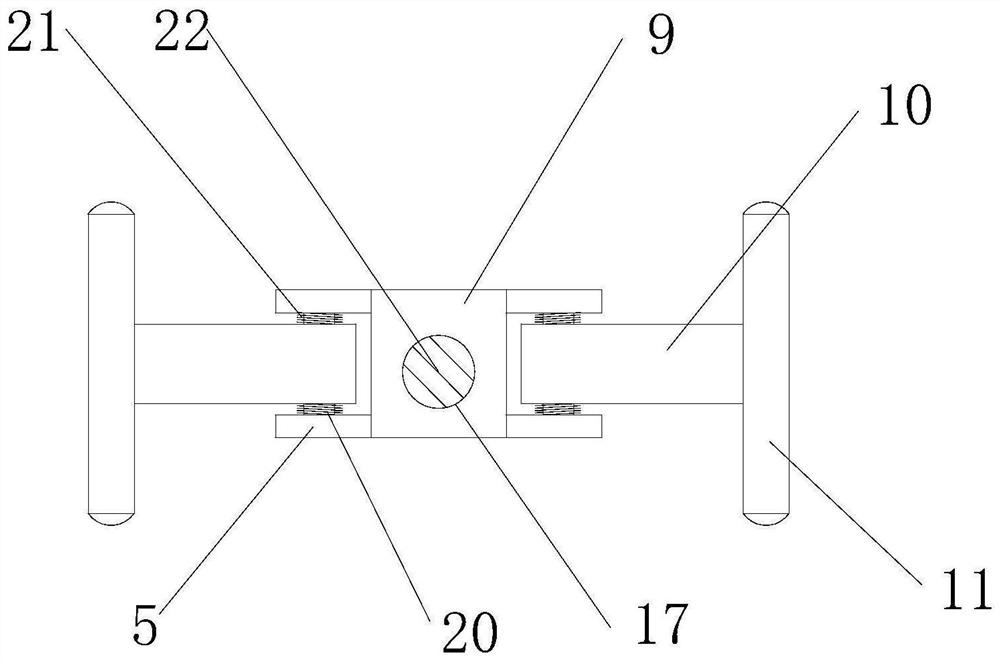

[0036] see Figure 1-5 , a plastic product strength detection device, including a mounting seat driving device 1, including a support seat 2;

[0037] A mounting seat driving device 1 is installed on the supporting base 2, and the output end of the mounting seat driving device 1 is connected with a fixture mounting seat 3 located above the supporting base 2, and the top end of the fixture mounting seat 3 is connected with a movable connecting seat 9, and the movable connecting seat 9 Both sides of the connecting ear assembly are provided with a connecting ear assembly, and the connecting ear assembly includes two connecting ears 5 arranged at intervals. The two connecting ears 5 are connected to a movable rod 10 through a connecting shaft 20 in rotation, and the end of the movable rod 10 is also connected to a support rod 11. A torsion spring 21 is also connected to the connecting shaft 20, and the torsion spring 21 acts on the movable rod 10, so that the movable rod 10 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com