Highway engineering drill core sampling device

A sampling device and engineering drill technology, applied in the direction of sampling devices, etc., can solve problems such as cumbersome operation, affecting test accuracy, and operational errors, and achieve the effect of simple operation and guaranteed sample accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

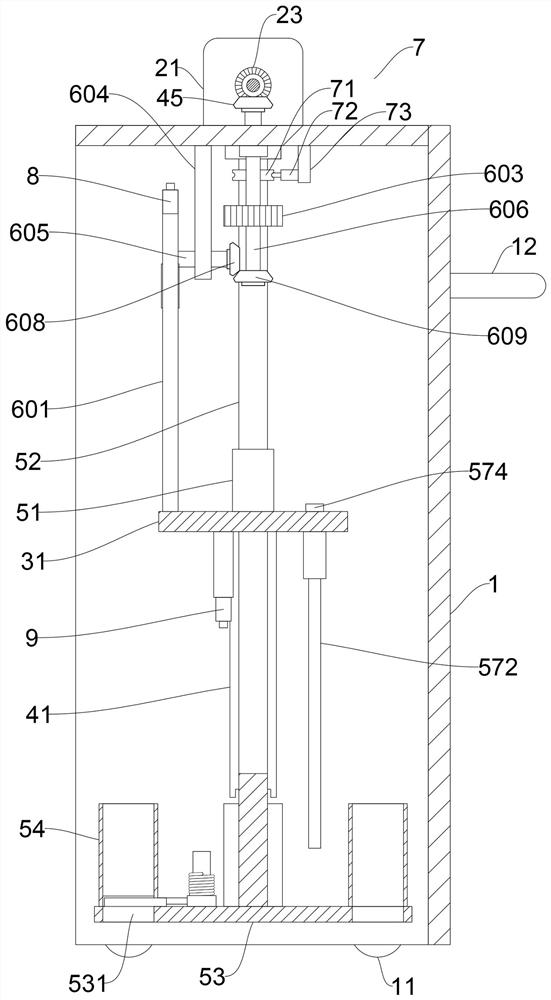

[0026] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 Shown: a highway engineering drilling core sampling device, including a frame 1, and:

[0027] The drive mechanism 2 for providing power, the drive mechanism 2 includes a long-axis motor 21 and a reducer 22, the long-axis motor 21 and the reducer 22 are installed on the frame 1, and the long-axis motor 21 and the reducer 22 are located on the top of the frame 1 , to facilitate power transmission, the output end of the long-axis motor 21 is connected to the input end of the reducer 22, and the output end of the long-axis motor 21 is equipped with a driving bevel gear 23;

[0028] The lifting mechanism 3 vertically lifts inside the frame 1, the lifting mechanism 3 includes a lifting frame 31, a ball screw, a first guide sleeve 32 and a first guide rod 33, the ball screw includes a screw 34 and a nut seat 35, the screw The upper end of 34 is connected to the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com