Rubber sleeve with mounting structure and pipeline for mounting rubber sleeve

A technology of installation structure and rubber sleeve, which is applied in the direction of valve shell structure, sewer pipe system, valve device, etc., can solve the problems of inconvenient maintenance, low construction efficiency, high cost, etc., and achieve convenient installation, convenient installation and maintenance, and prevent backflow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

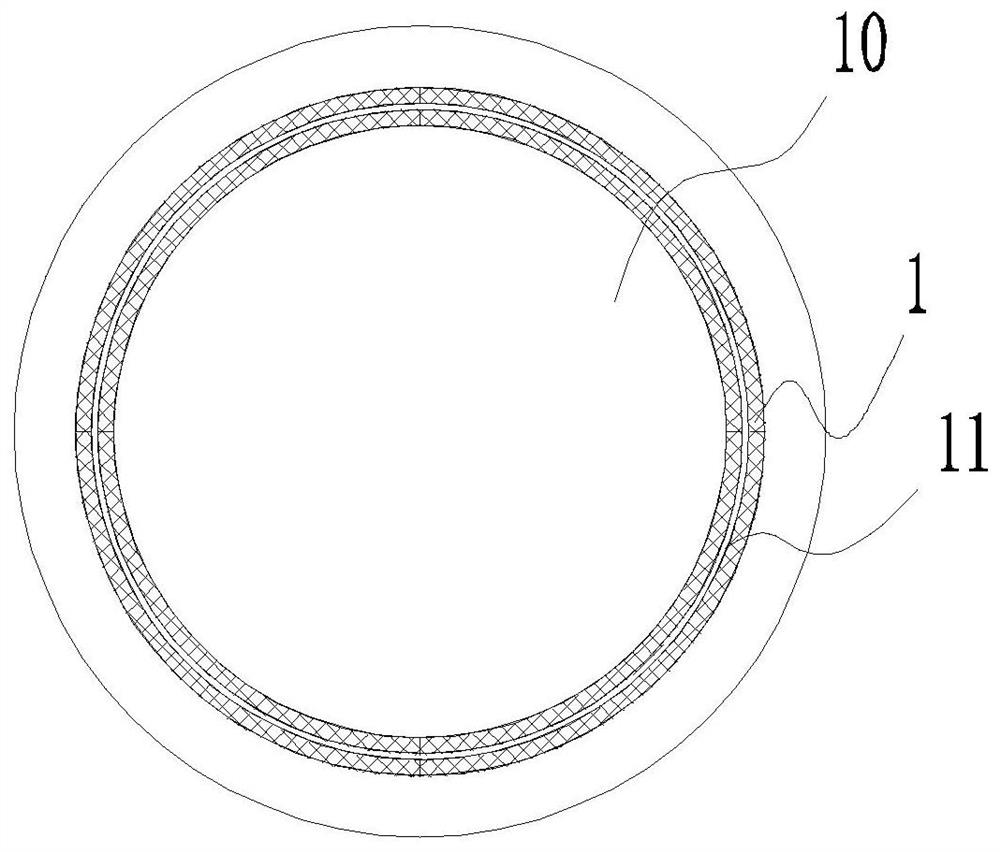

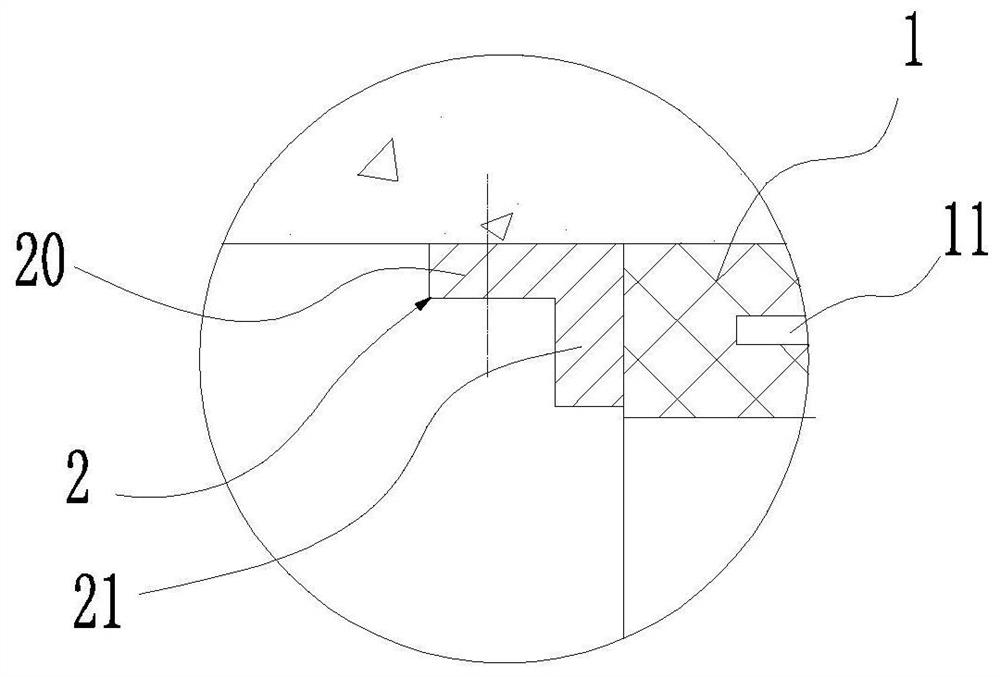

[0052] see Figure 1 to Figure 13 As shown, the present invention provides a rubber sleeve with a mounting structure, including a rubber sleeve 1 and a mounting structure, the rubber sleeve 1 is provided with a through flow passage 10, the rubber sleeve 1 is an integral structure, and the rubber sleeve 1 is provided with at least one independent pressure chamber 11, the rubber sleeve 1 is an integrated structure, and the rubber sleeve 1 is provided with at least one independent pressure chamber 11 at the position of each pressure chamber 11 1 has an outer rubber layer 12 and an inner rubber layer 13; each of the outer rubber layers 12 of the pressure chamber 11 is provided with an inlet and outlet hole, and the inlet and outlet holes communicate with the pressure chamber 11; the installation structure includes two limit positions Part 2, the two limiting parts 2 are fixed on both ends of the rubber sleeve 1 to clamp the rubber sleeve 1. In this embodiment, the rubber structur...

Embodiment 2

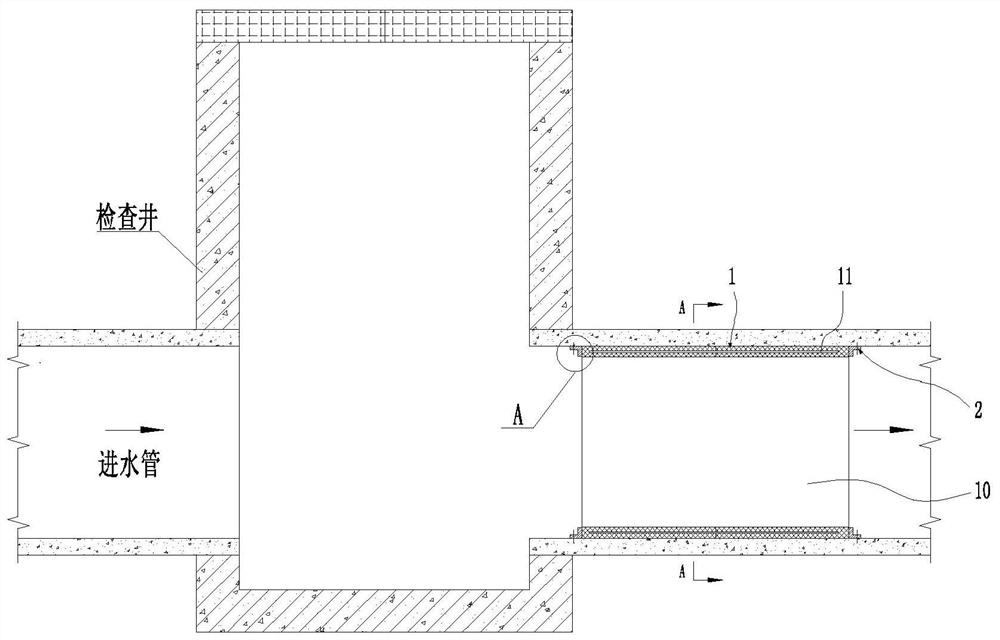

[0067] On the basis of embodiment 1, see figure 1 and Figure 12 Shown, a kind of pipeline, the rubber sleeve with installation structure of embodiment 1 is installed in the port 3 of pipeline;

[0068] The outer wall of the rubber sleeve 1 is attached to the inner wall of the port 3 of the pipe, and the limit part 2 of the installation structure 2 is fixed on the inner wall of the port 3 of the pipe at both ends of the rubber sleeve 1, and the rubber sleeve 1 is clamped on the limit Between bit parts 2.

[0069] or see also Figure 15-17 In another pipeline shown, the rubber sleeve with the installation structure of Embodiment 1 is installed in the port 3 of the pipeline; the outer wall of the rubber sleeve 1 is attached to the inner wall of the port 3 of the pipeline through the outer cover body 44, and the installation structure The limit part 2 of 2 is fixed at the port of the pipe, and is pressed against one end of the rubber sleeve 1 by the pressure plate, and one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com