Replacement damage type continuous wear-resistant pneumatic high-temperature butterfly valve

A high-temperature butterfly valve and pneumatic head technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of ineffective sealing, easy to generate loopholes, and reduced airtightness, so as to reduce loss, increase service life, Effect of reducing mechanical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

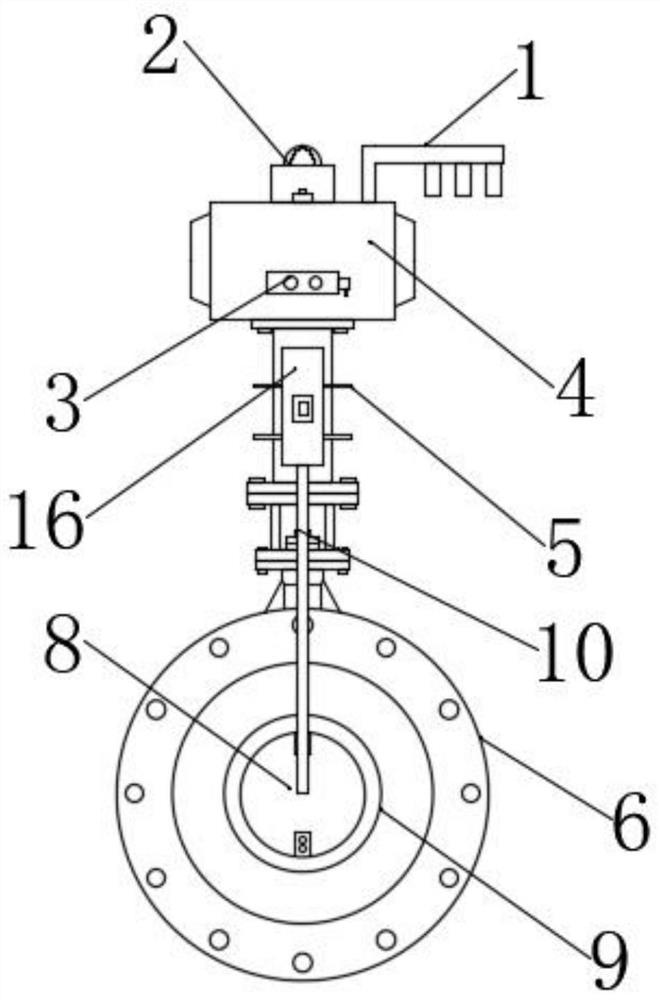

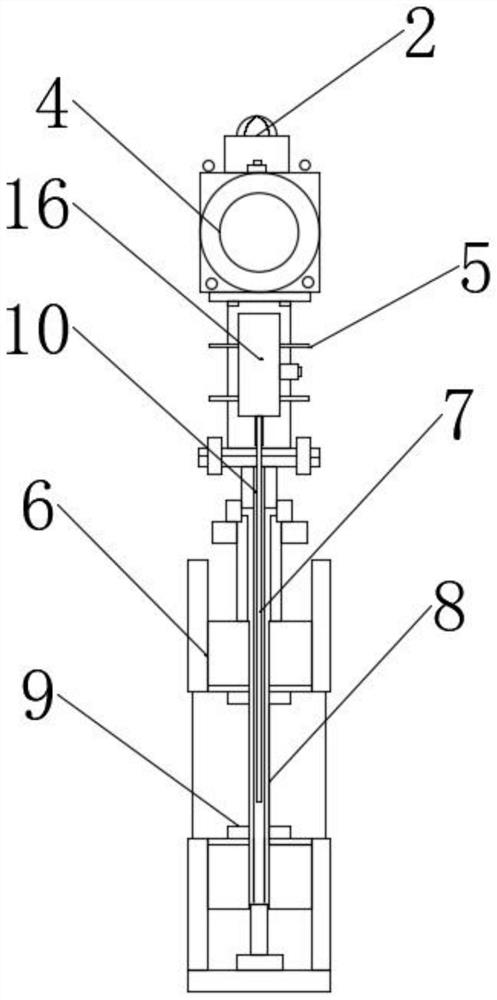

[0042] see Figure 1-2 , a replacement damage-type continuous wear-resistant pneumatic high-temperature butterfly valve, including a triple piece 1, the lower end of the triple piece 1 is fixedly connected with a pneumatic head 4, the upper end of the pneumatic head 4 is fixedly connected with a reply 2, and the outer end of the pneumatic head 4 is fixed. The solenoid valve 3 is connected, the lower end of the pneumatic head 4 is fixedly connected with the valve body 6, the outer end of the valve body 6 is fixedly connected with a plurality of cooling plates 5, the lower end of the pneumatic head 4 is connected with the valve stem 7 in rotation, and the valve stem 7 extends to In the valve body 6, the lower end of the valve stem 7 is fixedly connected with a valve plate 8, please refer to image 3 , the outer end of the valve plate 8 is fixedly connected with a sealing block 9, and the valve body 6 is provided with a storage bin 16, through which the restoration regeneration l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com