Vertical shaft construction method

A construction method and technology for shafts, which are applied in the directions of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as hole blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-5 The application is described in further detail.

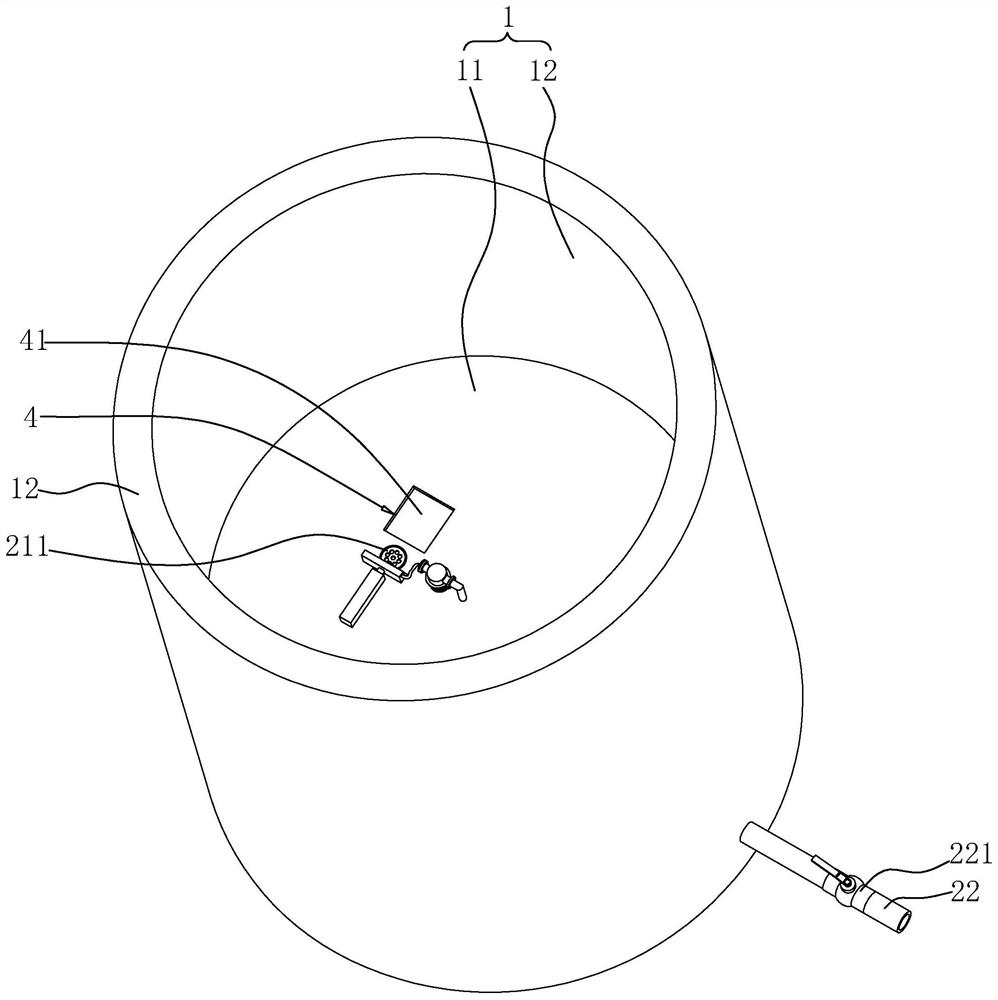

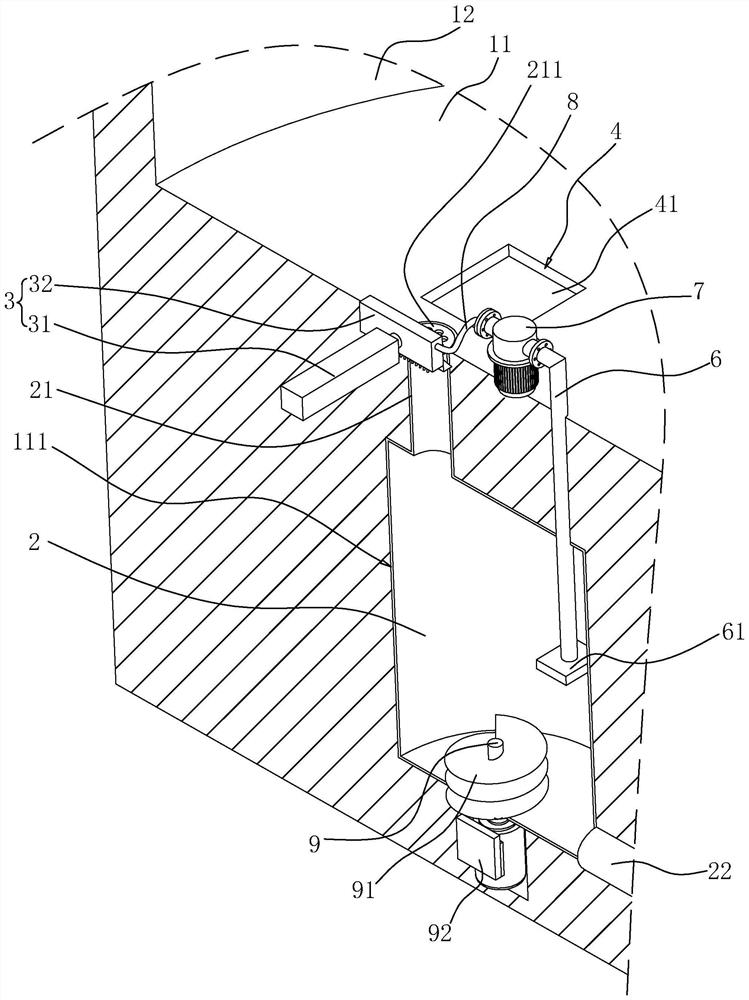

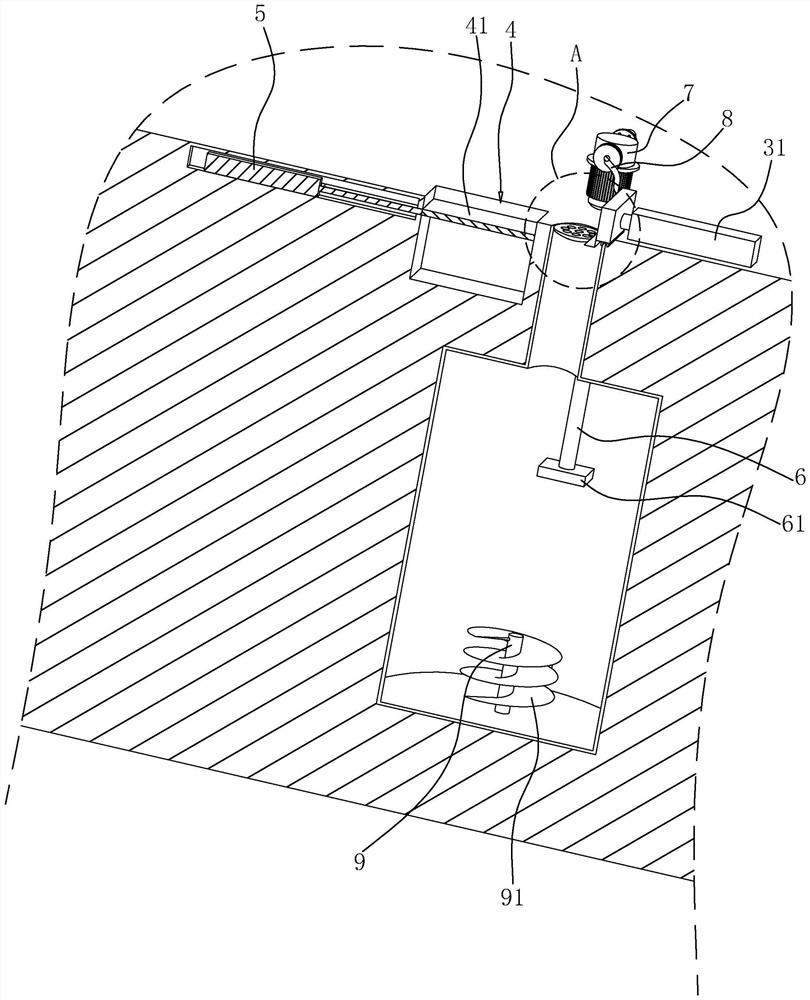

[0042] The embodiment of the application discloses a shaft construction method. refer to figure 1 and figure 2 , the shaft includes a bottom wall 11 and a side wall 12, the bottom wall 11 and the side wall 12 form a shaft space 1, the bottom wall 11 is provided with an installation groove 111, and a water collection tank 2 is arranged in the installation groove 111, and the top of the water collection box 2 is fixedly connected There is a water collection pipe 21, and a filter screen 211 is fixedly installed on the top of the water collection pipe 21. The upper surface of the filter screen 211 is flush with the upper surface of the bottom wall 11, and the bottom wall 11 is inclined to the filter screen 211 side to facilitate the accumulation of water in the shaft. Into the water collecting pipe 21. A drainpipe 22 is fixedly connected to one side of the water collecting tank 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com