Washing machine drain valve tractor

A drain valve and tractor technology, applied in the field of washing machines, can solve problems such as the failure of washing machines to work smoothly, and achieve the effect of ensuring smooth work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

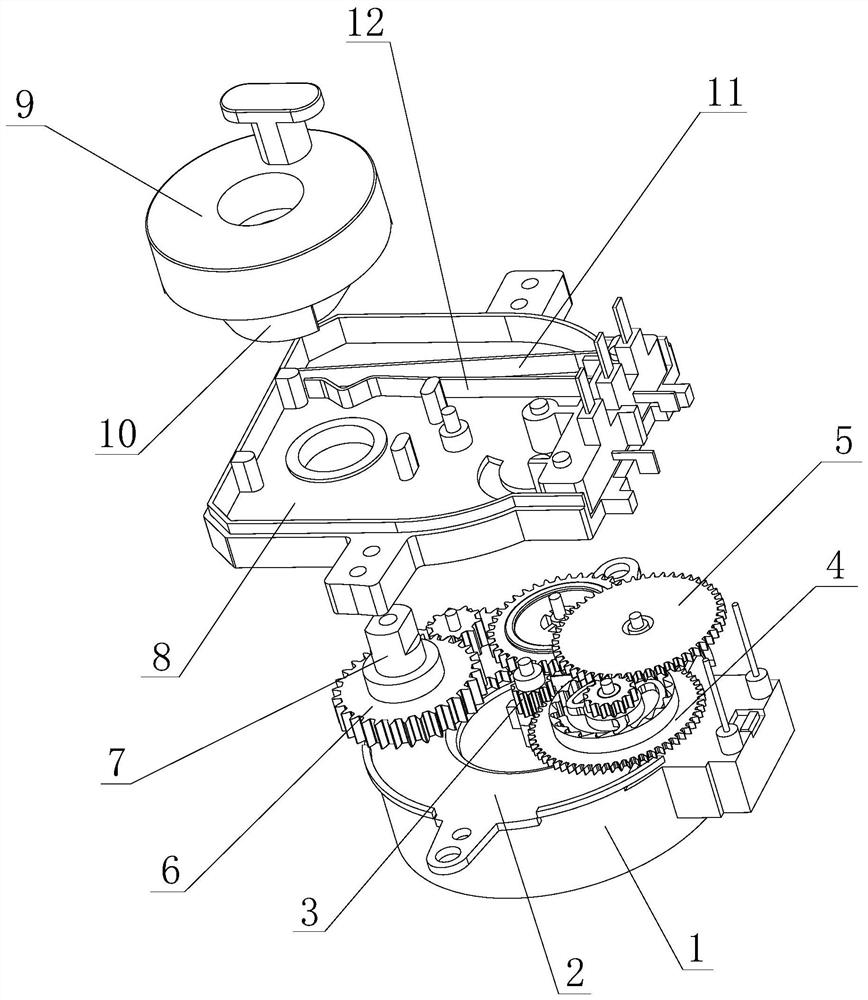

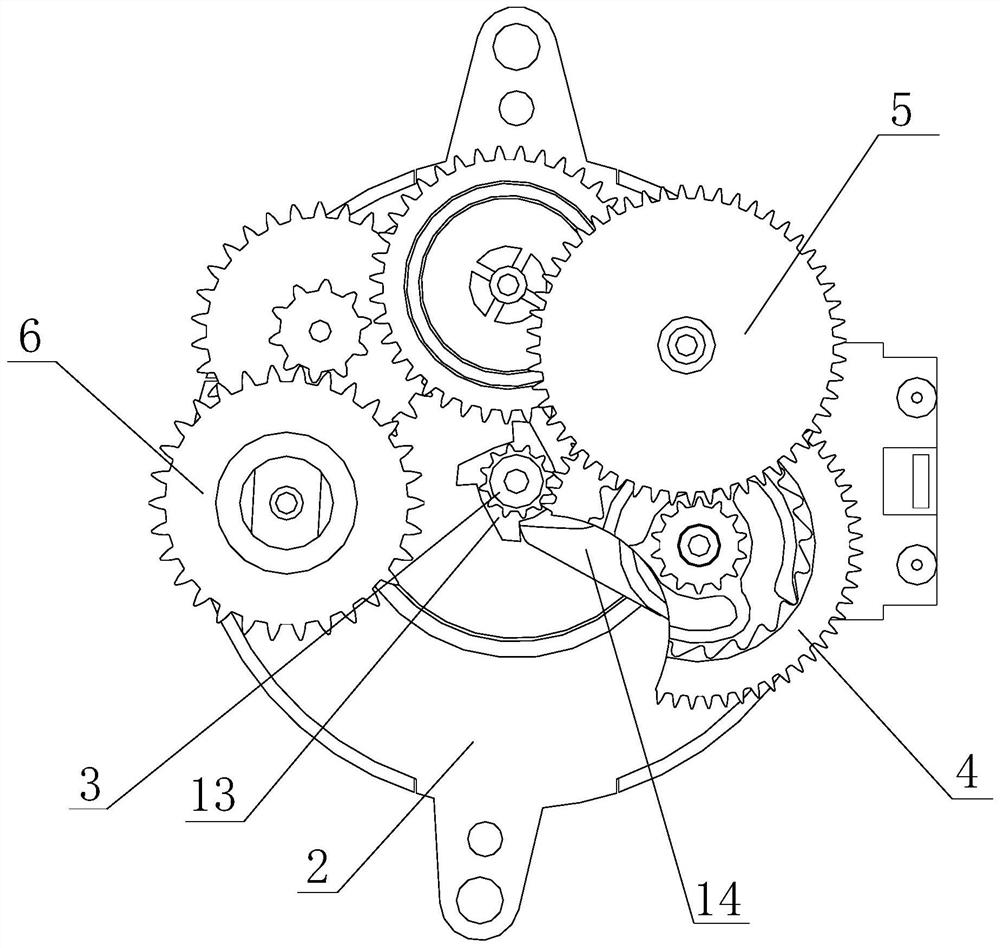

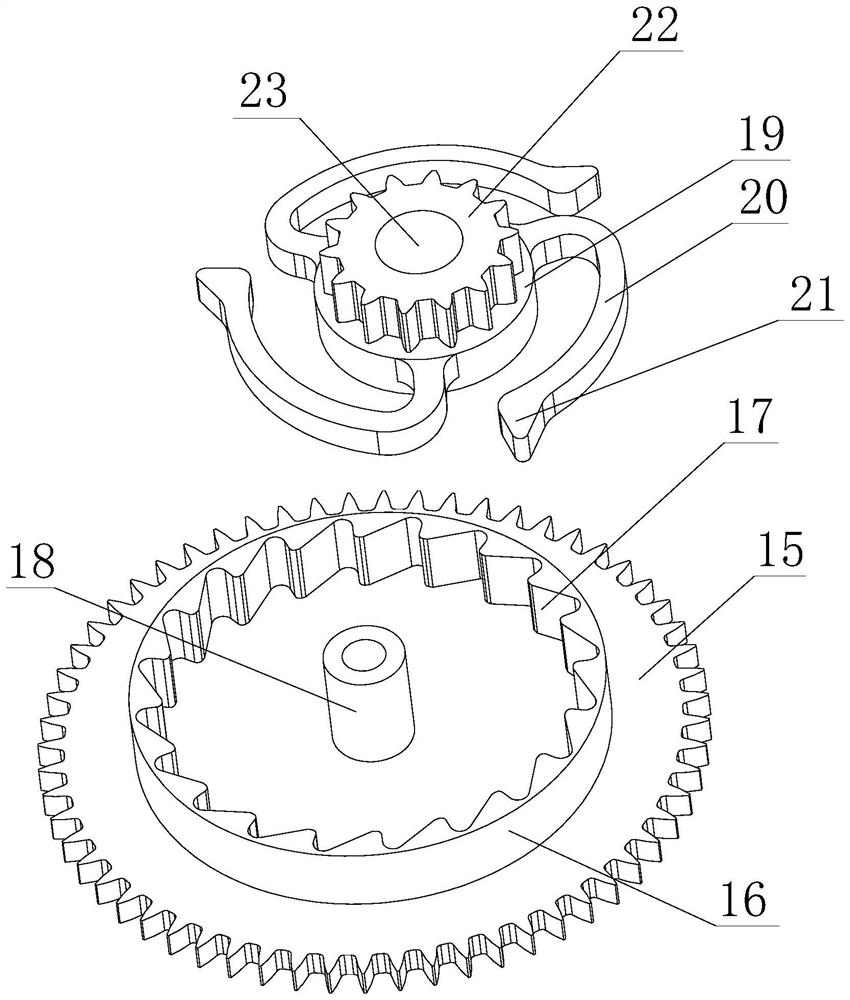

[0028] Such as Figure 1 to Figure 6 As shown, a puller for the drain valve of a washing machine includes a motor 1, a reduction mechanism and an electrical connection mechanism. Motor 1 is a synchronous motor. The reduction mechanism includes a first mounting plate 2 which is fixedly connected to the motor 1 . A one-way wheel 4 and a knob gear 6 are rotatably arranged on the first mounting plate 2 , and a plurality of sequentially connected intermediate transmission gears 5 are connected between the one-way wheel 4 and the knob gear 6 . An output gear 3 meshing with a one-way wheel 4 is arranged on the output shaft of the motor 1 . The knob gear 6 is provided with a connecting shaft 7, and the connecting shaft 7 is connected with a drainage knob 9. A protruding shaft is arranged eccentrically on the drain knob 9 . The electrical connection mechanism includes a second mounting board 8 connected to the first mounting board 2 . The second mounting plate 8 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com