Bearing material ring feeding and discharging device and using method thereof

A material ring and bearing technology, applied in the field of the bearing material ring loading and unloading device, can solve the problems of complex structure of the loading and unloading device, many mechanical actions, long loading and unloading time, etc., and achieves simple structure, less mechanical action, and short loading and unloading time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

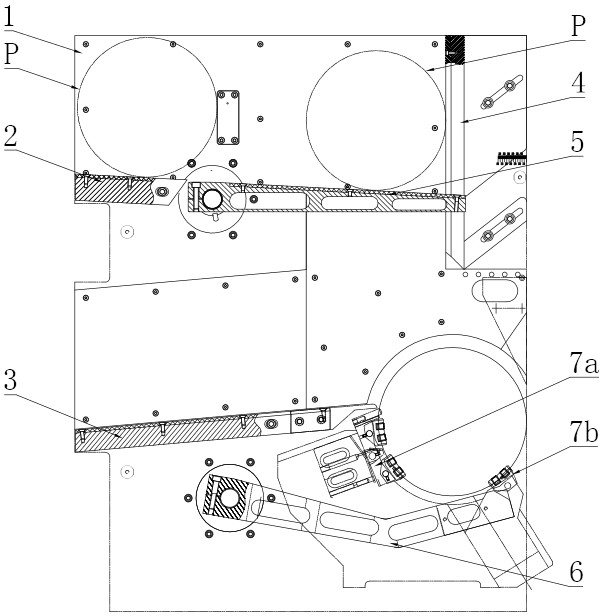

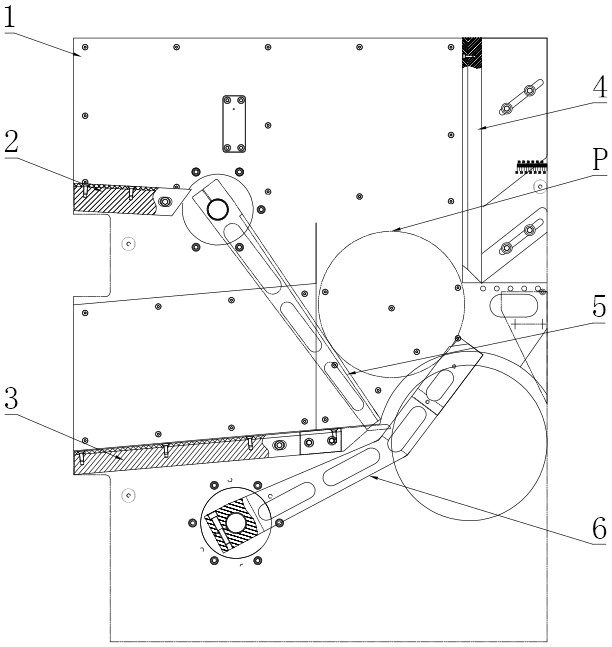

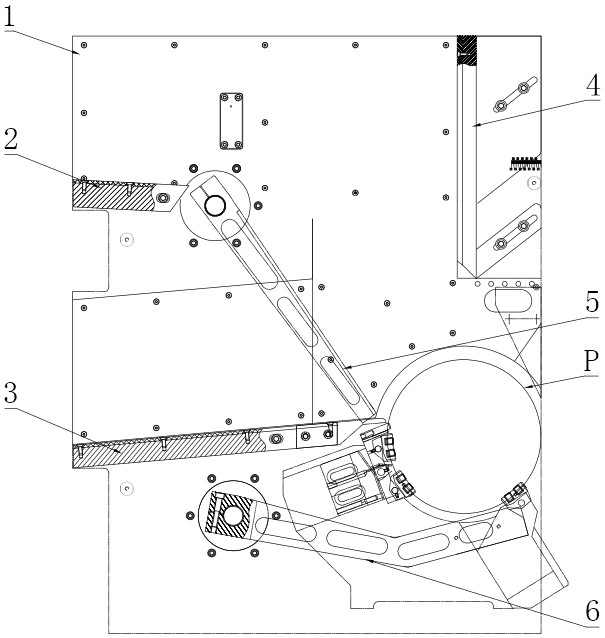

[0021] Such as figure 1 As shown, the loading and unloading device for the bearing material ring, wherein the bearing material ring P is an outer ring or an inner ring, and the device includes a front panel (not shown), a rear panel 1, a front panel and a rear panel 1 spaced apart from each other and arranged in parallel. The feed guide plate 2, the discharge guide plate 3, the transition guide plate 4, the material holder, and the upper rotating arm 5 and the lower rotating arm (not shown) are fixedly installed between them, and the feeding guide plate 2 faces downward to the right. Inclined setting, the discharge guide plate 3 is inclined to the lower left, so that the bearing material ring can roll down under the action of its own weight, the discharge guide plate 3 is located at the lower side of the feed guide plate 2, and the transition guide plate 4 is vertically arranged and located On the right side of the feed guide plate 2, the upper rotating arm 5 is located betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com